50+ Years of

Excellence & Expertise

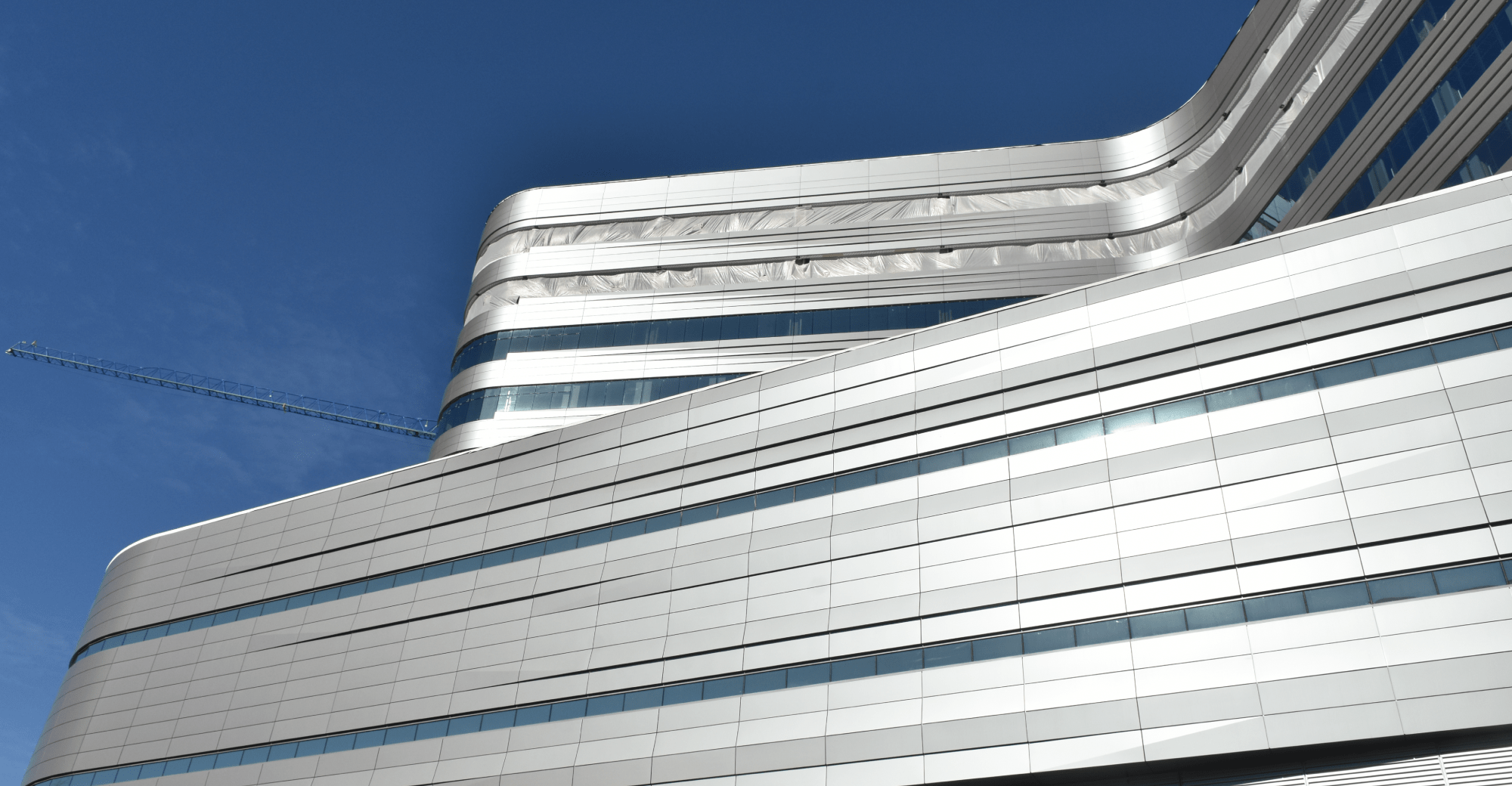

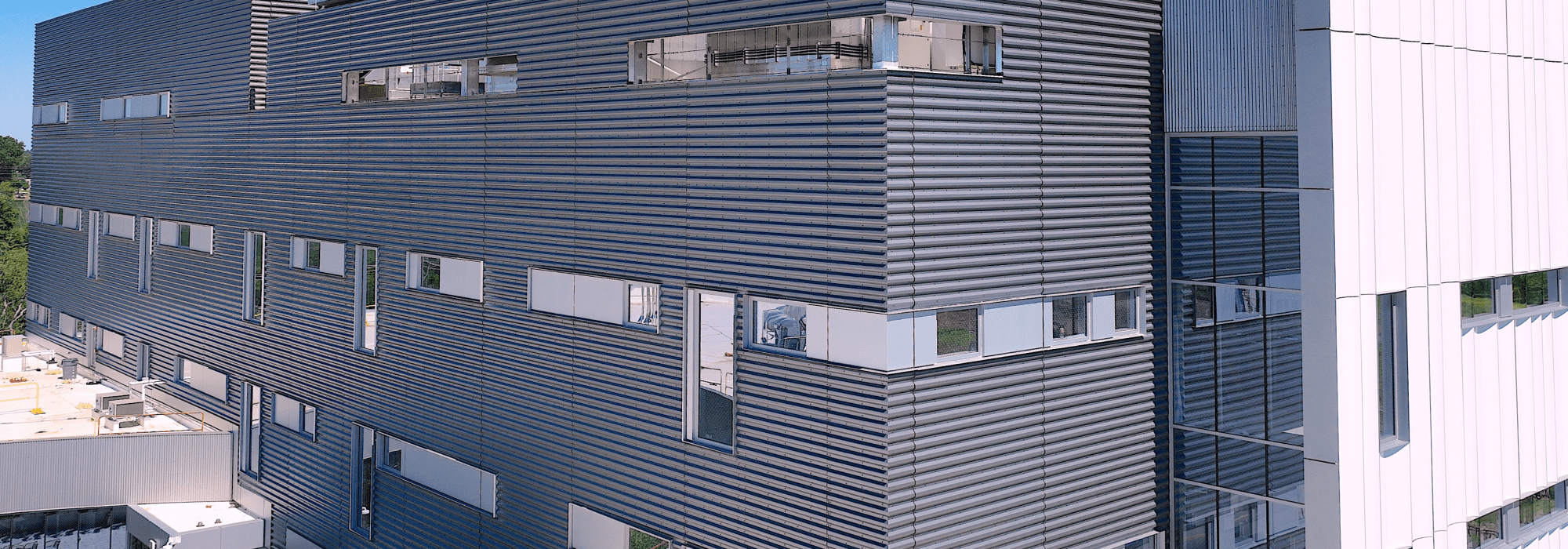

In the early 1970s, Eastern Exterior Wall Systems (EEWS) pioneered the prefabrication of exterior walls for large buildings. Since then, more than 20 million square feet of our prefabricated systems mark city landscapes from Boston to Charlotte and west to Chicago.

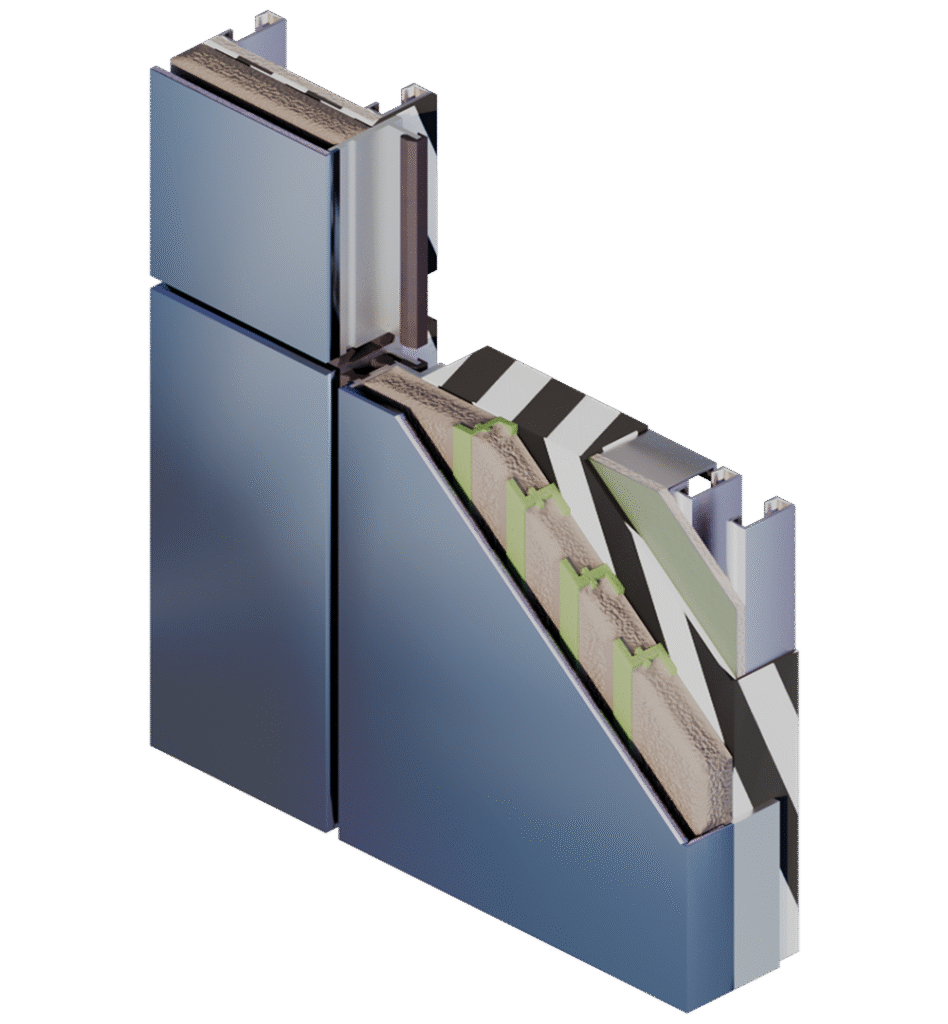

Each of EEWS’s projects are custom designed, manufactured and installed to the architect’s vision. Our systems include the wall framing outward to the finished cladding in either ventilated rainscreen or barrier performance models expertly integrated into one product.

Our systems are fabricated in 300,000 square feet of new climate-controlled facilities in Pennsylvania and New York.

Connect With Us

Prefabricated

Exterior Wall Systems

A high-quality prefabricated turnkey solution, from start to finish, provided in a design assist process by our team of experienced collaborative experts.

← Hover on image hotspots to explore.

Exterior Cladding

A lightweight yet highly durable manufactured aluminum product capable of producing very flat surfaces with crisp precise edges and complex shapes. Pans are manufactured in-house and are available in a wide variety of colors, finishes, woodgrains, or custom designs.

Learn More

We engineer the integration of windows and curtain wall units into our systems at our shop facility, thereby enabling the building to be fully enclosed at the time our panels are erected. EEWS has worked with many manufacturers and any quality manufacturer can be integrated.

Learn More

A thin single skin material typically formed from aluminum, zinc, or steel coil into numerous deep or shallow profile patterns, solid or perforated. Corrugated sheets are available from popular manufacturers in a variety of colors, textures, and finishes.

Learn More

Seamlessly integrated into our enclosure systems to service aesthetic and functional needs. Louvers are typically used in both active and inactive applications with integral blank offs and/or sound attenuation. Appearance can be presented as either trimmed sections or a seamless blade.

Learn More

EEWS successfully pioneered prefabricating EIFS system in the early 1970s. Providing creative flexibility and high thermal performance at the lowest cost. A variety of finishes are available such as Lymestone, granite, and stenciled brick.

Learn More

A solid aluminum product typically 1/8“ or 3/16” in thickness offering superior durability and fire resistance. Plate pans are produced in house and are available in a variety of colors and finishes either post painted heat-treated or coil coated depending on thickness.

Learn More

Terra cotta is a natural color fast clay product available in both large and small formats of varying thickness depending on the application. EEWS typically engages with manufacturers such as Shildan, Argeton, Boston Valley Terra Cotta, and Ludowici.

Learn More

Available as a barrier system on permabase or rainscreen system on a metal tray base. Accents, surrounds, stone, solider courses, arches, keystones, and corbeling are frequently integrated into EEWS’s systems.

Learn More

Fiber cement is a durable cementitious cladding material that offers the look of masonry with enhanced performance, moisture resistance, and long-term dimensional stability. Accents, surrounds, stone, soldier courses, arches, keystones, and corbeling are frequently integrated into EEWS’s systems.

Learn More

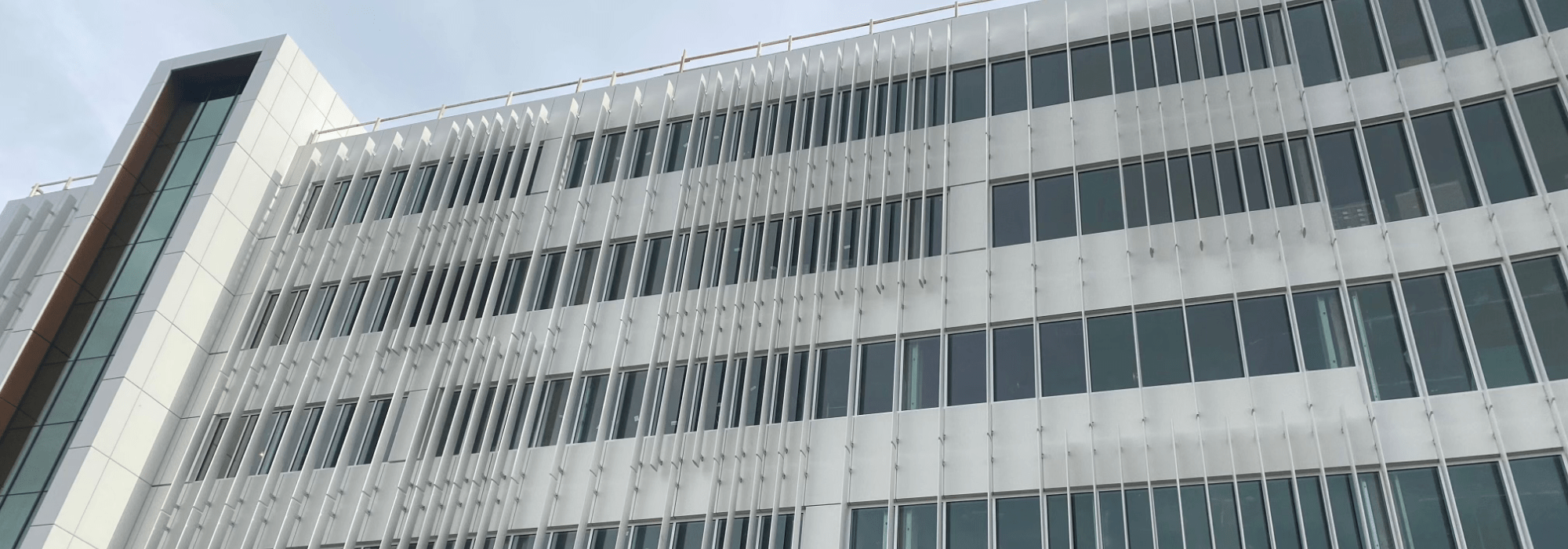

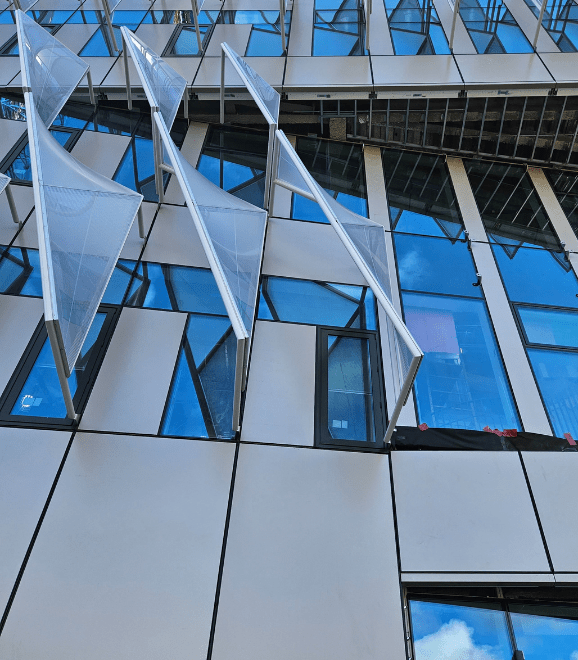

Fins, sunshades, and architectural accents improve solar control while adding depth and definition to the façade. These components integrate seamlessly into Eastern Exterior Wall Systems assemblies to create cohesive, high-performance building enclosures.

Learn MoreInsulation & Girts

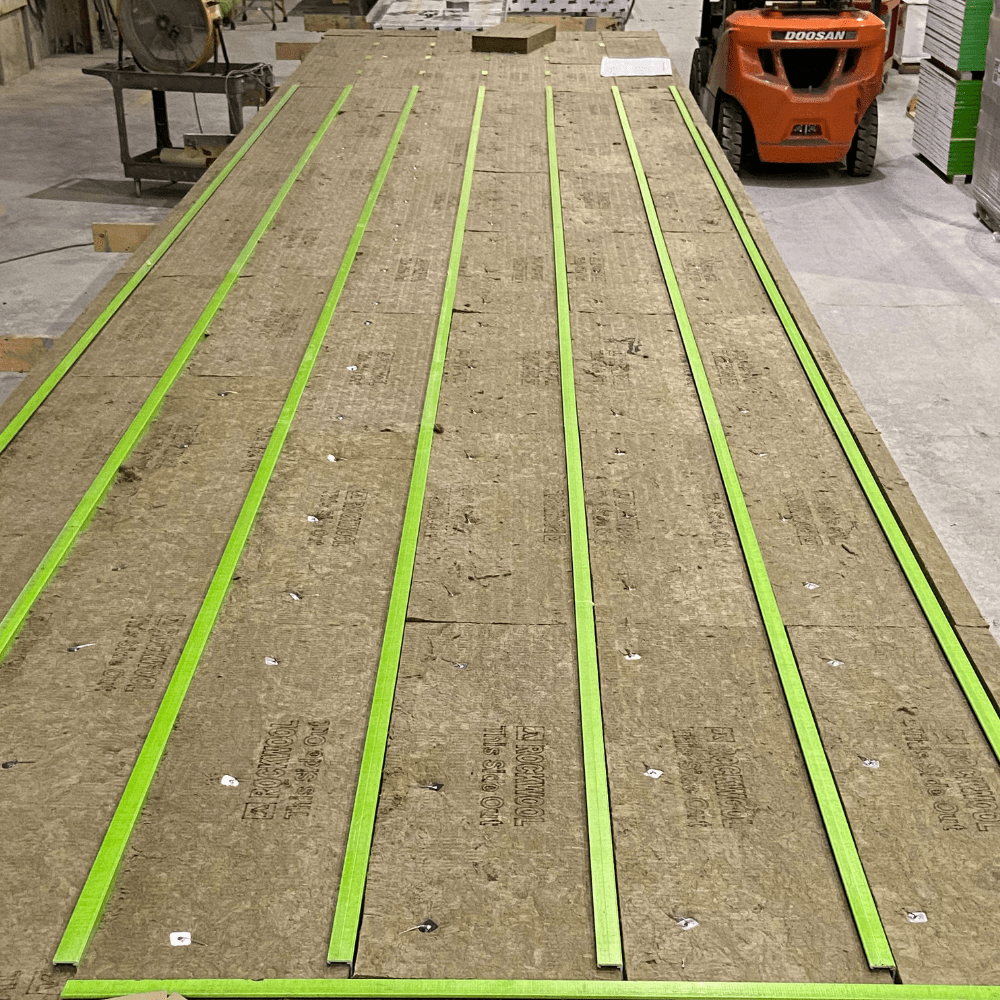

EEWS’s systems are engineered with internal girts to provide proper support for the outboard cladding materials. Girts range from galvanized to thermally neutral fiberglass, to aluminum, to stainless steel. We use various types of insulation within our systems, including Polyisocyanurate Boards, Mineral Wool, and Rigid Foam.

Learn MoreSheathing

Extrusions & Gaskets

Our dry gasket system delivers superior weather resistance and faster installation timelines.

Learn MoreFraming

Framing serves as the structural backbone of our wall panel systems. We engineer and fabricate the framing that provides the necessary support for the exterior cladding and other panel components. Each frame is precisely designed to meet the building’s structural, thermal, and performance requirements.

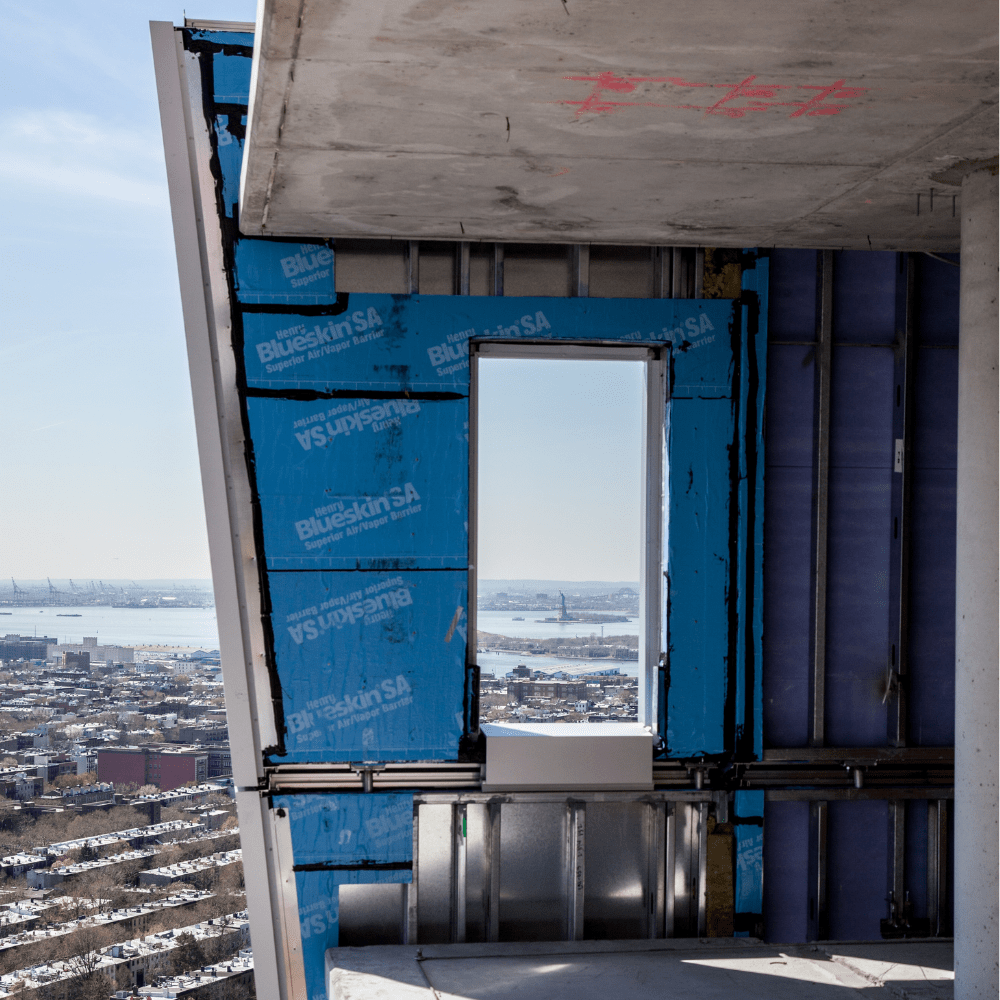

Learn MoreAVB

Integrated early in the design and fabrication process, the Air Vapor Barrier (AVB) ensures that our enclosures meet the highest standards for moisture management, air infiltration control, and thermal performance.

Learn MoreA Turnkey Solution, High Quality Support From Start To Finish

Design Assist

Our collaborative process unites one experienced team from design through installation. In-house Revit-certified designers ensure every detail is carefully planned and executed. Early alignment on goals and continuous design and budget feedback keep projects on track. This streamlined approach eliminates inefficiencies and delivers reliable, high-quality results.

Fabrication Process

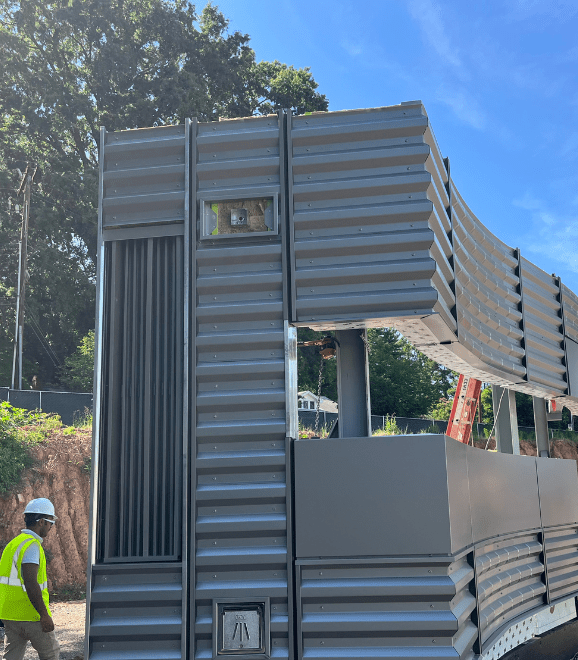

Prefabrication involves designing and manufacturing high-performance Exterior Wall Systems in a controlled environment before they reach the job site. These systems integrate components like structural framing, insulation, and cladding into complete, ready-to-install Exterior Wall Panels. By building off-site, Exterior Wall Systems significantly reduce installation time, improve quality, and minimize safety risks. Each of our precision-engineered Exterior Wall Panels is fabricated to exact specifications, eliminating the inconsistencies of on-site construction. Through early planning and coordinated engineering, Exterior Wall Systems simplify complex construction workflows and accelerate building enclosure. With integrated joints and finishes, Exterior Wall Panels arrive prefinished and require minimal site work. The durability and performance of our Exterior Wall Systems enhance energy efficiency and long-term value. Meanwhile, the clean installation of Exterior Wall Panels supports safer, more organized jobsites. Built under strict quality control, Exterior Wall Systems eliminate weather-related delays and reduce rework. Thanks to their factory-level precision, Exterior Wall Panels deliver consistent results across projects. By consolidating trades and components, Exterior Wall Systems streamline scheduling and reduce coordination issues. The sleek, modern look of our Exterior Wall Panels also elevates architectural aesthetics while meeting performance demands.

Tab 7 : fabrication Process #3

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Tab 4 : Design Process #1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Tab 6 : Fabrication Process #2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Installation Process

Our innovative Exterior Wall Systems are fully fabricated and pre-assembled to ensure speed, accuracy, and reduced on-site labor. Each of our Exterior Wall Panels is precision-manufactured in a controlled environment, enabling faster installation with minimal field adjustments. By using Exterior Wall Systems, projects benefit from improved safety, less scaffolding, and fewer workers at height. The integration of pre-finished Exterior Wall Panels also accelerates building enclosure, allowing interior work to start sooner. With our efficient Exterior Wall Systems, jobsite coordination is smoother and more predictable. Additionally, the consistent quality of our Exterior Wall Panels enhances long-term durability and aesthetic appeal. The early dry-in capability of our Exterior Wall Systems protects interior trades from weather delays. Meanwhile, streamlined Exterior Wall Panel installation shortens construction timelines and lowers costs. Our approach to delivering complete Exterior Wall Systems helps reduce project complexity and overall risk. Combining function and form, our Exterior Wall Panels offer a high-performance envelope solution for commercial and institutional buildings. Utilizing modern Exterior Wall Systems leads to faster schedules and improved build quality. With our factory-built Exterior Wall Panels, you get a cleaner, safer, and more efficient construction process.

Tab 9 : Installation Process #2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Tab 10 : Installation Process #3

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Design Assist

EEWS’s Design Assist process hinges on communication and bringing the skill and experience of the owner, construction manager, architect, engineer, and consultants together early in development to find optimal solutions to complex problems.

Our highly experienced in-house team of engineers, Revit certified designers, and production specialists work to develop the details needed for the proper constructability of the system, all while we monitor the design evolution and provide budget and constructability feedback to the team. Our team acts as a single point of coordination ensuring the highest quality exterior wall systems.

Prefabrication

Prefabrication is the process of manufacturing the complex wall systems developed and engineered during design assist. They are produced in our controlled environment facility in Allentown — before they reach the construction site. Prefabrication offers major advantages compared to stick-built methods done onsite. EEWS delivers the benefits of prefabrication to each project it undertakes for optimum solutions and reliable efficient production.

Maximizing The benefits Of Prefabrication

Design Assist

Our collaborative process unites one experienced team from design through installation. In-house Revit-certified designers ensure every detail is carefully planned and executed. Early alignment on goals and continuous design and budget feedback keep projects on track. This streamlined approach eliminates inefficiencies and delivers reliable, high-quality results.

Safer Job Site

Our panelized enclosure system reduces on-site labor and shortens the project timeline, cutting labor costs. Pre-engineered and assembled off-site, it eliminates material storage, site congestion, and waste. Fewer trades are needed on-site, creating a cleaner, safer work environment. This streamlined process also lowers the risk of accidents and boosts site efficiency.

Quality Assurance

Our panelized systems provide superior thermal, moisture, and air performance through a continuous, high-quality enclosure. Assembled in a controlled facility, components like AVB, windows, and louvers are installed with precision. A single expert team handles multiple trades, reducing gaps and delays. This process also simplifies inspections and ensures consistent quality.

Building Enclosure Speed

Prefabricated panel systems greatly speed up the building enclosure process. Off-site fabrication in a controlled environment allows for faster dry-in and earlier interior work. This reduces weather delays and shortens the overall schedule. It’s an ideal solution for projects with tight timelines or phased occupancy.

Coordinated Engineered Interfaces Solutions

Our system features fully coordinated, engineered interfaces for seamless integration of all enclosure components. Key details are resolved during design and fabrication, avoiding on-site conflicts. This approach minimizes field adjustments and ensures consistent quality. The result is a unified, high-performing building envelope from day one.

Logistics

Prefabricated enclosure systems streamline logistics by reducing the volume of material delivered to and stored on-site. With just-in-time delivery and panels arriving in sequence, site congestion, waste, and handling are minimized. This controlled flow of materials supports cleaner, safer job sites and simplifies coordination among trades. The result is a more efficient, organized construction process that aligns with modern lean building practices.

Thermal Performance

When design allows, increasing opaque wall areas with prefabricated systems can greatly improve thermal performance. Fewer unitized joints enhance energy efficiency and air-tightness. These systems also offer broad cladding flexibility, giving architects more design freedom. In this case, the prefabricated enclosure is over four times more energy efficient than a traditional glass curtain wall.

Recent Projects

Discover our work and embrace the quality and passion we deliver into every project to create remarkable architecturally designed experiences.

Borgata Hotel, Casino & Spa

Atlantic City

Cornell Tech Residential Building

new york city

Court Street Regal Theater Complex

Brooklyn

Prudential Center

Newark

Expertly Crafted Prefabricated Wall Panels For Any Project

Discover how our high-performance panels enhance aesthetics, energy efficiency, and durability.

Contact Us To Learn More

Need something custom for your fabrication project? Contact us to discuss your project details.

Industry Features

Stay informed and learn about our services through in depth content.