Our Design Assist Approach

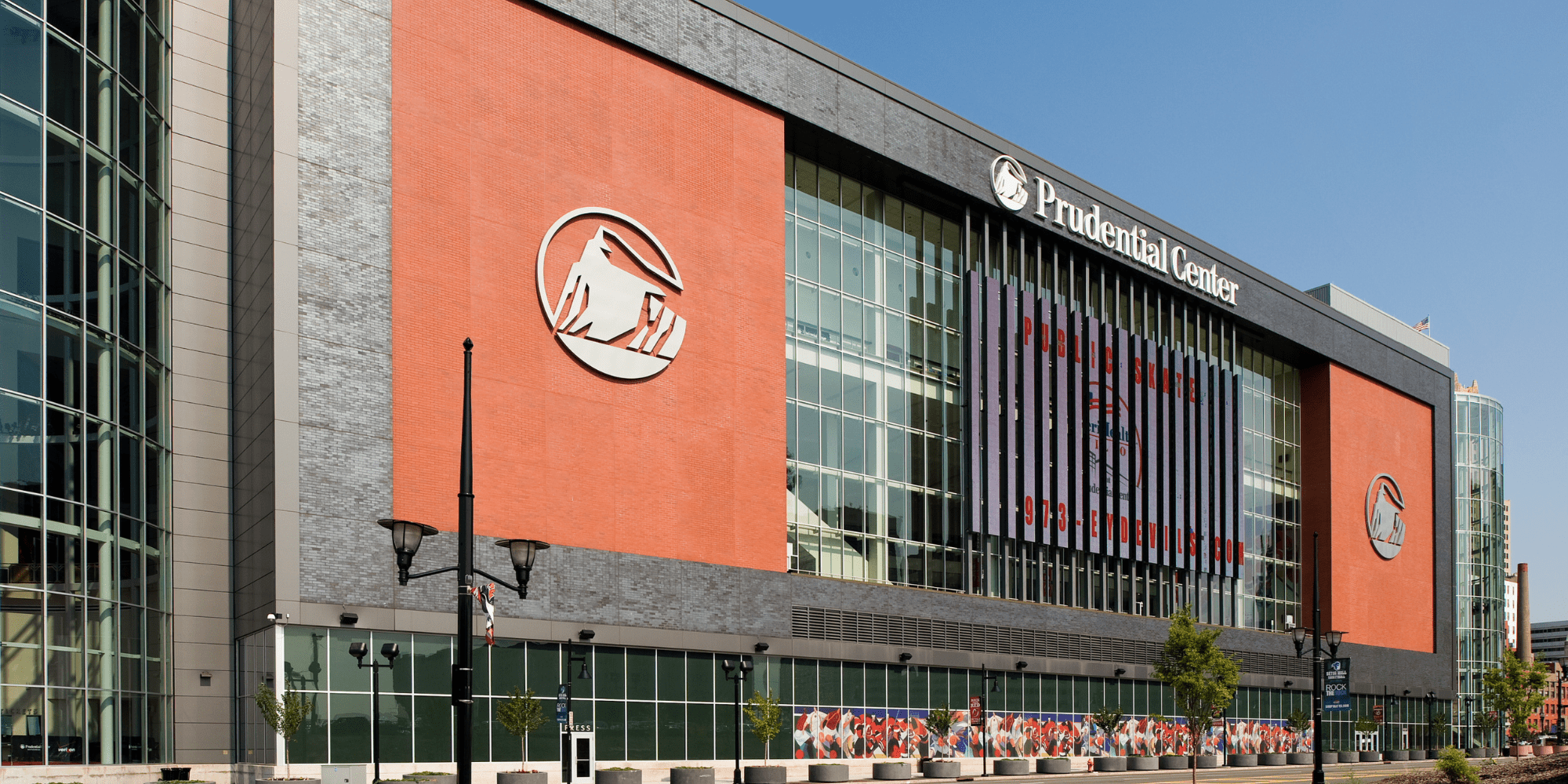

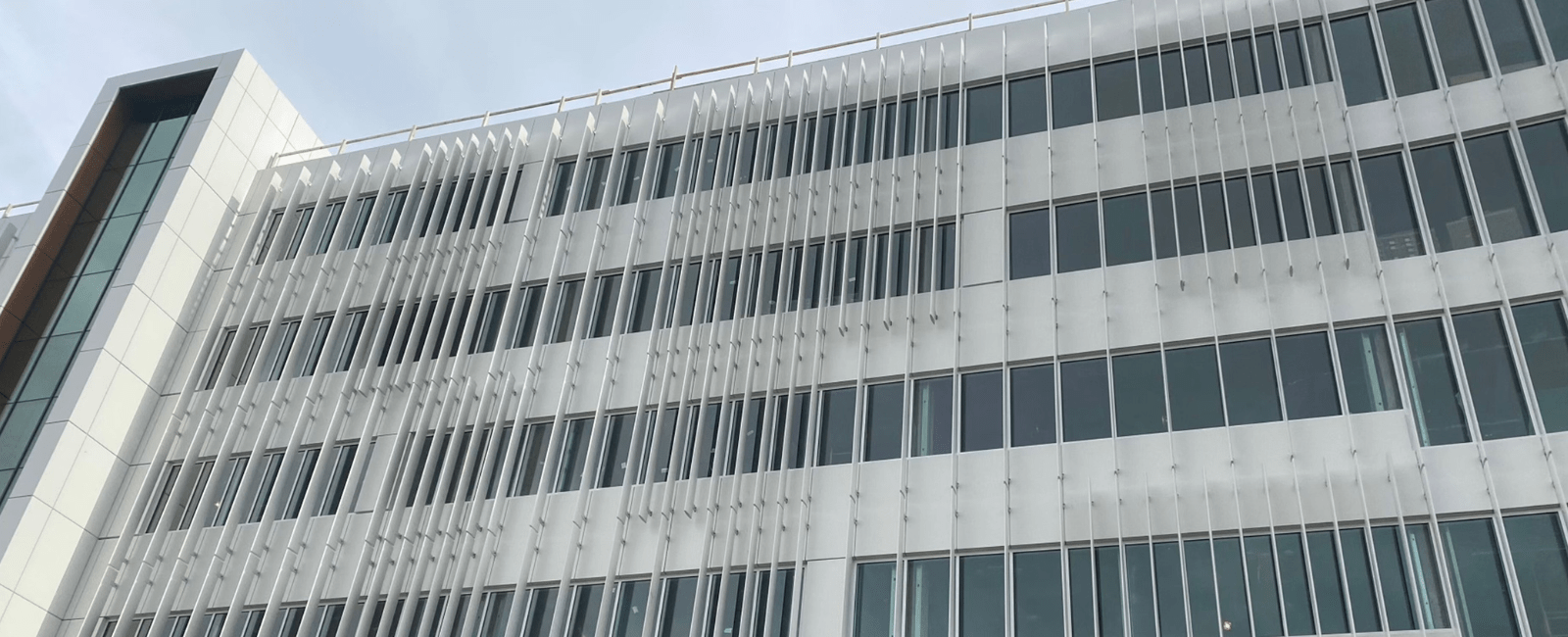

Working with experienced partners and maintaining clear timely communication we deliver a unified approach—from design through fabrication to final installation. Our team acts as a single point of coordination ensuring the highest quality exterior wall systems are delivered on time and budget.

The Design Assist process brings the skill and experience of each project stakeholder together early in development to find optimum solutions and create reliable efficient project production.

EEWS’s approach is rooted in a true spirit of collaboration among the owner, construction manager, architect, engineer, and consultants. From day one, EEWS’s highly experienced in-house team of engineers, designers, drafters (all Revit certified), production specialists, and managers offer best practices to ensure the proper details, accuracy, and constructability are integrated into the exterior wall system.

Design Assist produces the best results when a realistic budget and schedule are set, the team is aligned on project goals, early agreement is reached on key design details and performance characteristics, and good coordination is an everyday thought.

During the Design Assist Process EEWS:

Develops The Details

Detailing is critical to project success. EEWS develops effective details for every component of its systems. This precision enables us to produce high quality shop drawings, installation guides, and CNC outputs directly from our BIM environment.

Models The Building Geometry

EEWS begins by modeling the building geometry in Revit, which forms the digital backbone of our Design Assist services and sets the stage for accurately planning the integration of the exterior wall system. We capture building dimensions, slab edges, façade offsets, structural grids, identify structural clashes, and design nuances with a high degree of accuracy. This virtual model facilitates collaboration with the team by eliminating data silos and consolidating building information into one easy to view tool.

Maps The Panel Layout

EEWS then maps the panel layout, a critical step, in the Design Assist workflow. We segregate each facade into optimally sized panels based on architectural design criteria, aesthetic expectations, crane capacity, structural requirements, material transitions, and shipping logistics.

Analyzes Panel Components

Many of EEWS’s systems integrate window, vent, louver, sunshade, and other design feature components into the panels. We conduct a comprehensive analysis of these components to ensure they are structurally sound, weathertight, drain properly, maintain AVB continuity, thermally efficient, of proper dimension, provide material adhesion compatibility, and attached correctly.

Analyzes Proof of Structural Design

Structural analysis provides validation for each component of EEWS’s systems. We use advanced modeling tools to simulate loading conditions — including wind, seismic, dead loads, deflection, stress distribution, anchorage performance, and building movement — to ensure every EEWS panel is structurally robust, code compliant, will perform safely and durably over the life of the building.

Provides Thermal Analysis

To meet energy efficiency goals, EEWS evaluates the thermal performance of its systems using advanced simulation tools to assess insulation continuity, R-values, U-factors, monitor LEED goals, and identify thermal bridging risks across joints, fasteners, and support structures.

Design Assist Provides Thermal Analysis

To meet energy efficiency goals, EEWS evaluates the thermal performance of its systems using advanced simulation tools to assess insulation continuity, R-values, U-factors, monitor LEED goals, and identify thermal bridging risks across joints, fasteners, and support structures.

Design Assist Models The Building Geometry

EEWS begins by modeling the building geometry in Revit, which forms the digital backbone of our Design Assist services and sets the stage for accurately planning the integration of the exterior wall system. We capture building dimensions, slab edges, façade offsets, structural grids, identify structural clashes, and design nuances with a high degree of accuracy. This virtual model facilitates collaboration with the team by eliminating data silos and consolidating building information into one easy to view tool.

Thermal Analysis

To meet energy efficiency goals, we evaluate the thermal performance of all Exterior Wall Systems using advanced simulation tools. We assess insulation continuity, R-values, U-factors, and identify thermal bridging risks across joints, fasteners, and support structures.

Our team provides recommendations for insulation types, placement strategies, and integration of air/vapor barriers within the Exterior Wall Panels. This ensures continuous thermal protection, reduces energy loss, and supports LEED or local green building certifications. Thermal analysis is also vital for interior comfort, condensation control, and envelope longevity.

Model The Details

Detailing is where Design Assist comes full circle. Every component of the Exterior Wall Panels — from connections and gaskets to clips, sealants, and finishes — is modeled to fabrication-level detail. These precision models enable us to produce shop drawings, installation guides, and CNC outputs directly from our BIM environment.

We ensure all elements are coordinated with the building geometry and adjacent systems. Whether it’s a transition to roofing, slab edge detail, or louver frame, we model the interfaces carefully to support airtight, watertight, and structurally sound assemblies. This level of detail helps eliminate RFIs, reduces field labor, and ensures that Exterior Wall Systems are delivered and installed exactly as intended.

Model The Building Geometry

The process begins by modeling the full building geometry using BIM (Building Information Modeling). This 3D model forms the digital backbone of our Design Assist services and sets the stage for accurately planning the integration of Exterior Wall Panels. We capture building dimensions, slab edges, façade offsets, structural grids, and design nuances with a high degree of accuracy.

This virtual model also acts as a single source of truth, fostering collaboration and eliminating data silos. It allows us to coordinate effectively with the design and construction teams, ensuring the Exterior Wall Systems are tailored to the building’s structure, movement, and layout. Modeling early reduces misalignment, catches potential conflicts, and supports fast, accurate updates throughout the design phase.

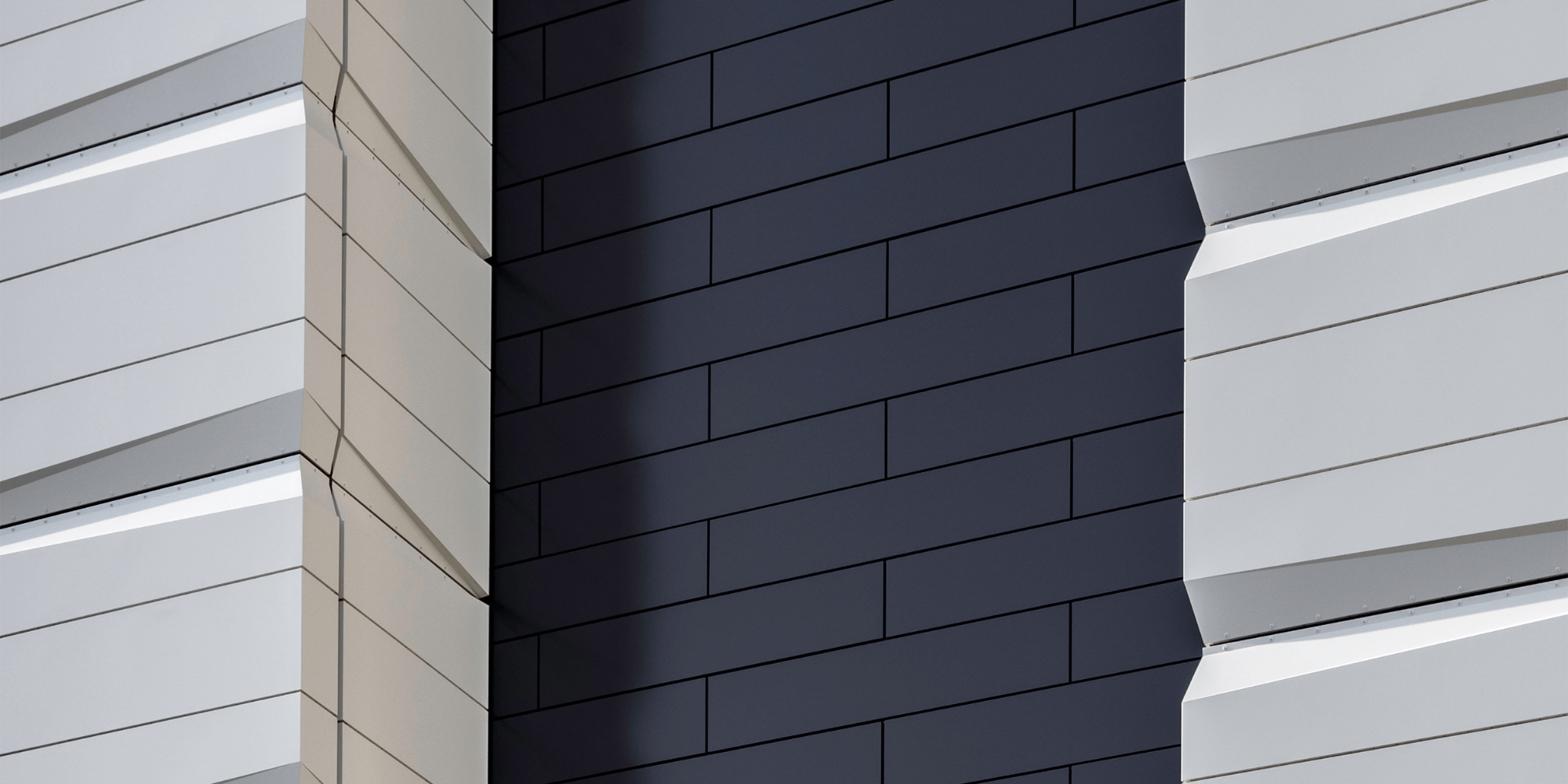

Map The Panel Layout

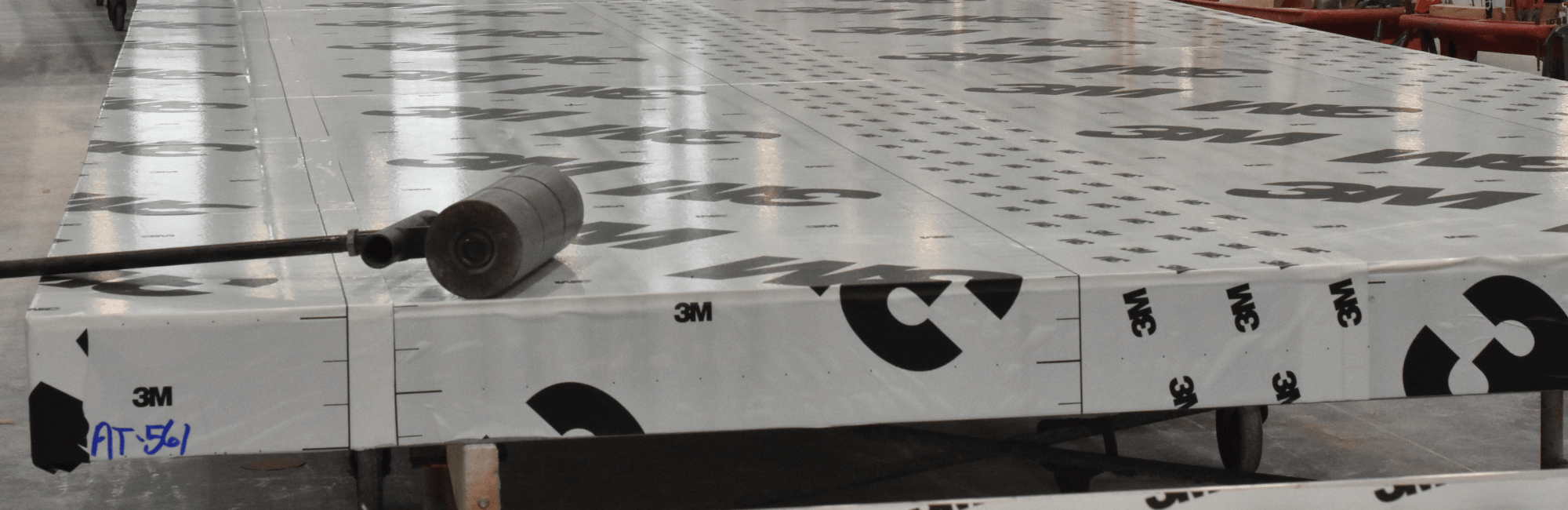

Mapping the panel layout is one of the most critical tasks in the Design Assist workflow. We break down each facade into strategically sized Exterior Wall Panels based on crane capacity, structural requirements, material transitions, and shipping logistics. This layout ensures the panels are as complete as possible before arriving onsite — often incorporating cladding, waterproofing, insulation, and fenestration in a single assembly.

Every Exterior Wall System layout is tailored for optimal constructability while maintaining the architectural design. We identify efficient break lines, joint locations, and alignment strategies that minimize onsite labor and reduce the potential for errors. This early layout stage is also key to sequencing installations and coordinating interface points with adjacent trades.

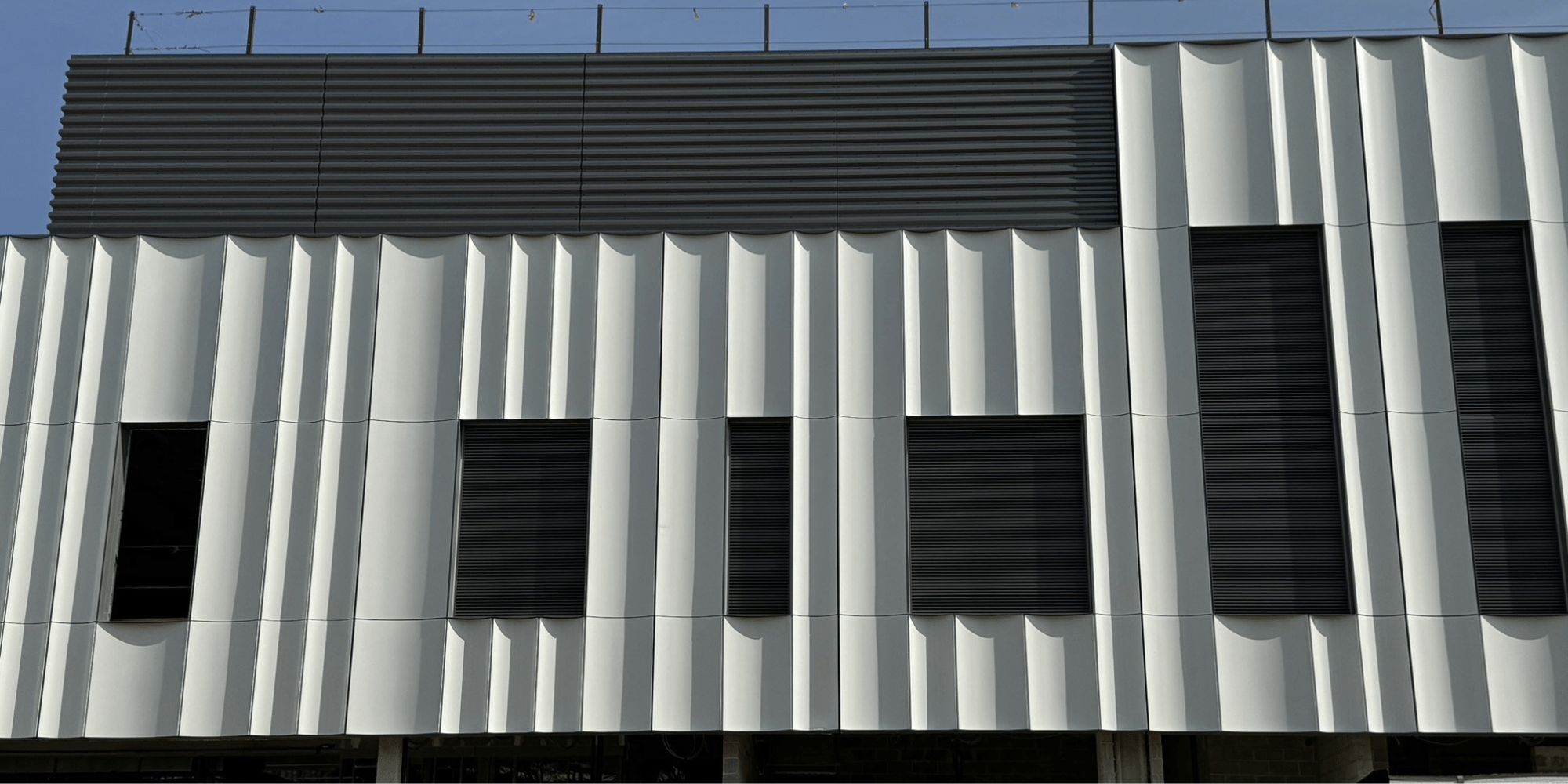

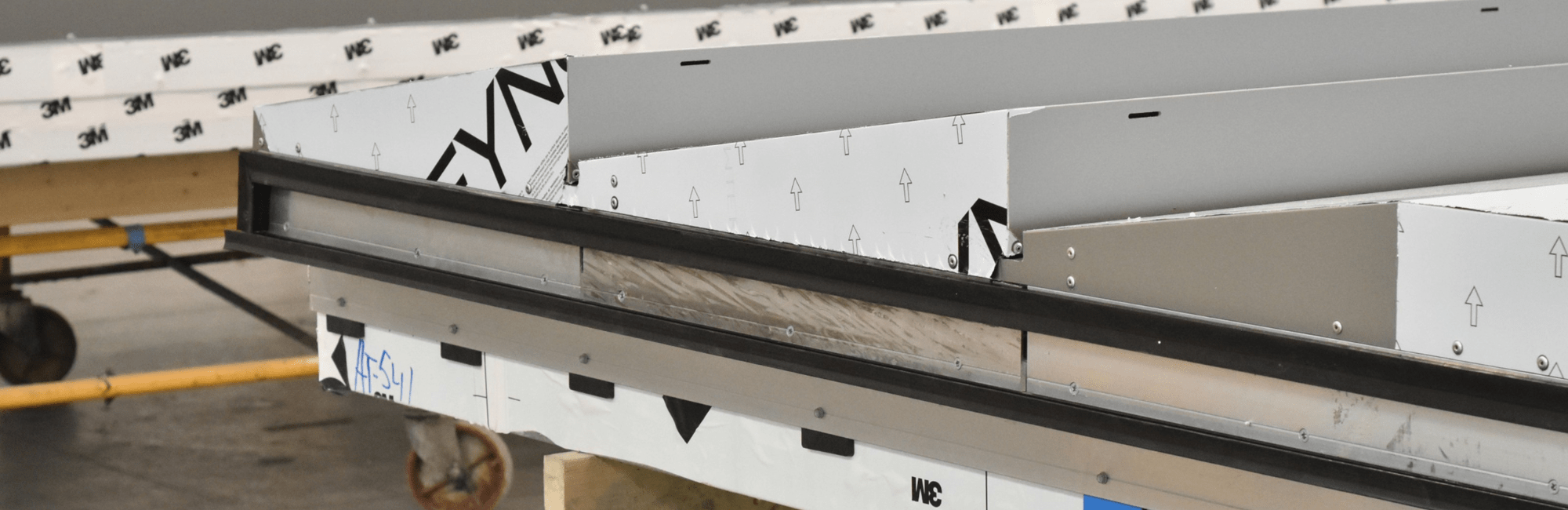

Analyze Panel Window / Louver Components

Many Exterior Wall Panels feature integrated components like windows, vents, and louvers. We conduct a comprehensive analysis of these elements to ensure they are structurally supported, weathertight, and thermally efficient. During this process, we evaluate rough opening dimensions, attachment points, drainage paths, flashing details, and barrier continuity.

All components are coordinated with the base Exterior Wall Systems to guarantee compatibility. This includes checking for tolerance conflicts, anchoring integrity, and aesthetic alignment. Our goal is to eliminate the need for on-site modification, resulting in a prefabricated product that fits together seamlessly and performs flawlessly under real-world conditions.

Proof Of Design Structural Analysis

Structural analysis provides engineering validation for each component of the Exterior Wall Systems. We use advanced modeling tools to simulate loading conditions — including wind, seismic, dead loads, and building movement — to ensure every Exterior Wall Panel is structurally robust and code-compliant.

This analysis also includes testing for deflection, stress distribution, anchorage performance, and overall system stability. Our engineers review connection points and develop reinforcement strategies where needed, helping eliminate field-level failures and delays. This step provides owners, architects, and general contractors with peace of mind that the Exterior Wall Panels will perform safely and durably across the life of the building.

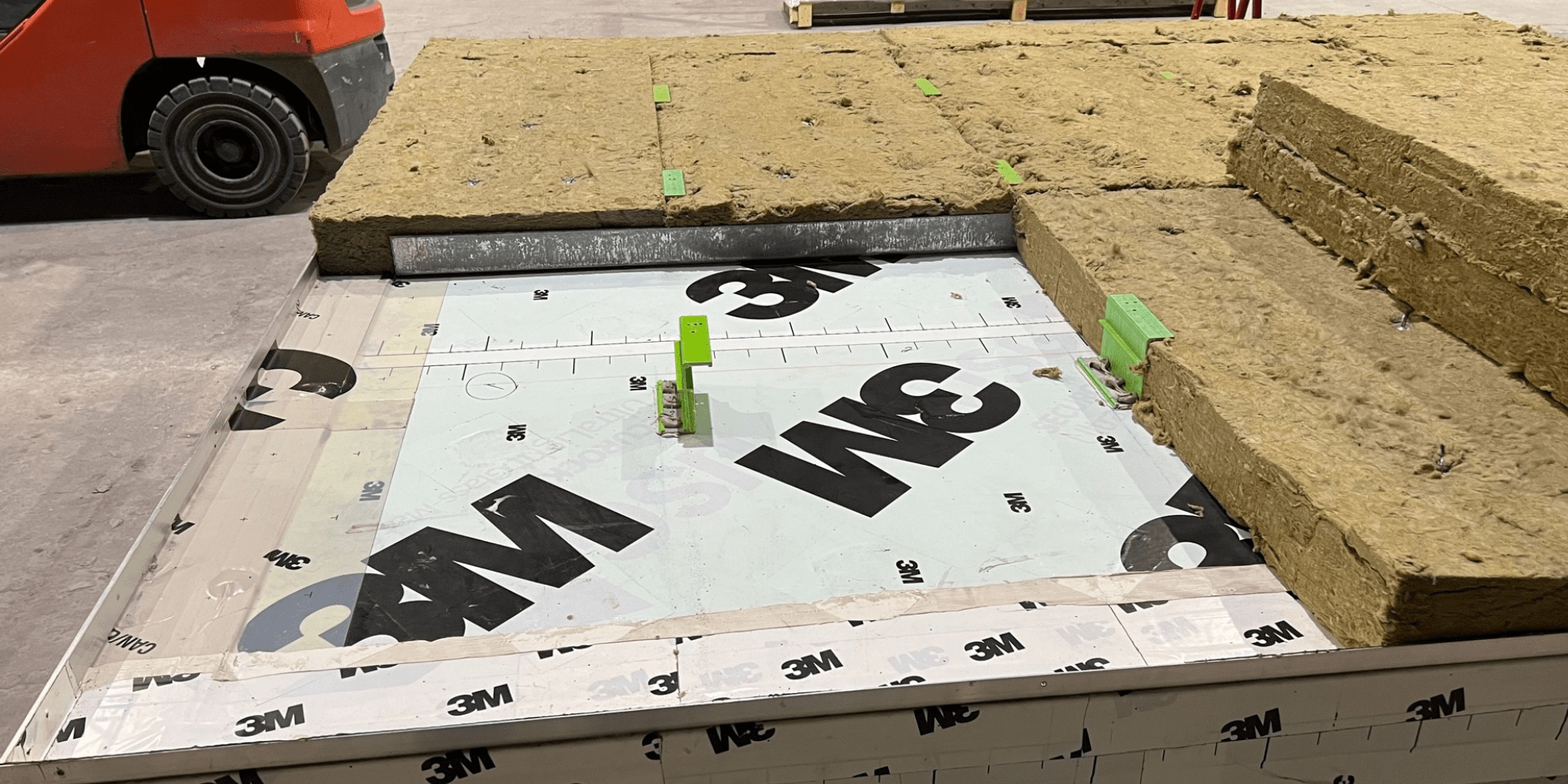

Thermal Analysis

To meet energy efficiency goals, we evaluate the thermal performance of all Exterior Wall Systems using advanced simulation tools. We assess insulation continuity, R-values, U-factors, and identify thermal bridging risks across joints, fasteners, and support structures.

Our team provides recommendations for insulation types, placement strategies, and integration of air/vapor barriers within the Exterior Wall Panels. This ensures continuous thermal protection, reduces energy loss, and supports LEED or local green building certifications. Thermal analysis is also vital for interior comfort, condensation control, and envelope longevity.

Model The Details

Detailing is where Design Assist comes full circle. Every component of the Exterior Wall Panels — from connections and gaskets to clips, sealants, and finishes — is modeled to fabrication-level detail. These precision models enable us to produce shop drawings, installation guides, and CNC outputs directly from our BIM environment.

We ensure all elements are coordinated with the building geometry and adjacent systems. Whether it’s a transition to roofing, slab edge detail, or louver frame, we model the interfaces carefully to support airtight, watertight, and structurally sound assemblies. This level of detail helps eliminate RFIs, reduces field labor, and ensures that Exterior Wall Systems are delivered and installed exactly as intended.

Contact Us To Learn More

Need something custom for your fabrication project? Contact us to discuss your project details.

FAQ

Frequently asked questions asked by our clients regarding our fabrication services.

What is Design Assist in exterior wall systems?

What is Design Assist in exterior wall systems?

Design Assist is a collaborative project delivery method that integrates architects, engineers, and builders early in the design phase to optimize exterior wall systems. This approach ensures accurate modeling, efficient fabrication, and seamless installation, enhancing overall project efficiency.

How does Building Information Modeling (BIM) enhance the Design Assist process?

How does Building Information Modeling (BIM) enhance the Design Assist process?

BIM provides a detailed 3D model of the building’s geometry, facilitating precise planning and coordination of exterior wall panels. It helps identify potential conflicts early, ensuring that the panels align perfectly with the building’s structure.

What are the benefits of integrating components like windows and louvers in Design Assist?

What are the benefits of integrating components like windows and louvers in Design Assist?

Integrating components such as windows and louvers during the Design Assist phase ensures structural support, weather tightness, and thermal efficiency. This integration streamlines installation and enhances the performance of the exterior wall system.

How does early panel layout mapping contribute to project success?

How does early panel layout mapping contribute to project success?

Early mapping of panel layouts considers factors like crane capacity, structural requirements, and shipping logistics. This strategic planning ensures that panels arrive on-site ready for installation, reducing labor and potential errors.

Why choose EEWS Design Assist approach for your project?

Why choose EEWS Design Assist approach for your project?

EEWS Design Assist approach offers a unified team from design through installation, ensuring efficiency, accuracy, and timely delivery of exterior wall systems. Their in-house Revit-certified designers and collaborative process lead to enhanced performance and long-term success.

Maximizing The benefits Of Prefabrication

Design Assist

Our collaborative process unites one experienced team from design through installation. In-house Revit-certified designers ensure every detail is carefully planned and executed. Early alignment on goals and continuous design and budget feedback keep projects on track. This streamlined approach eliminates inefficiencies and delivers reliable, high-quality results.

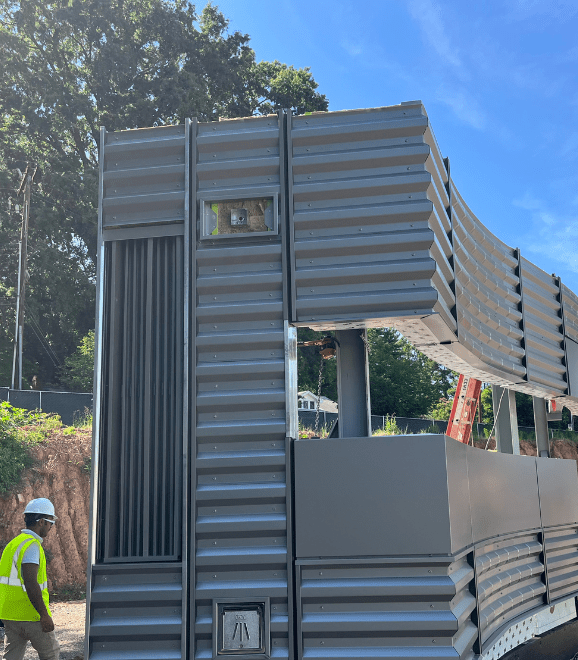

Safer Job Site

Our panelized enclosure system reduces on-site labor and shortens the project timeline, cutting labor costs. Pre-engineered and assembled off-site, it eliminates material storage, site congestion, and waste. Fewer trades are needed on-site, creating a cleaner, safer work environment. This streamlined process also lowers the risk of accidents and boosts site efficiency.

Quality Assurance

Our panelized systems provide superior thermal, moisture, and air performance through a continuous, high-quality enclosure. Assembled in a controlled facility, components like AVB, windows, and louvers are installed with precision. A single expert team handles multiple trades, reducing gaps and delays. This process also simplifies inspections and ensures consistent quality.

Building Enclosure Speed

Prefabricated panel systems greatly speed up the building enclosure process. Off-site fabrication in a controlled environment allows for faster dry-in and earlier interior work. This reduces weather delays and shortens the overall schedule. It’s an ideal solution for projects with tight timelines or phased occupancy.

Coordinated Engineered Interfaces Solutions

Our system features fully coordinated, engineered interfaces for seamless integration of all enclosure components. Key details are resolved during design and fabrication, avoiding on-site conflicts. This approach minimizes field adjustments and ensures consistent quality. The result is a unified, high-performing building envelope from day one.

Logistics

Prefabricated enclosure systems streamline logistics by reducing the volume of material delivered to and stored on-site. With just-in-time delivery and panels arriving in sequence, site congestion, waste, and handling are minimized. This controlled flow of materials supports cleaner, safer job sites and simplifies coordination among trades. The result is a more efficient, organized construction process that aligns with modern lean building practices.

Thermal Performance

When design allows, increasing opaque wall areas with prefabricated systems can greatly improve thermal performance. Fewer unitized joints enhance energy efficiency and air-tightness. These systems also offer broad cladding flexibility, giving architects more design freedom. In this case, the prefabricated enclosure is over four times more energy efficient than a traditional glass curtain wall.

Material Options

From cladding, to integration, and components.