Sub Girts

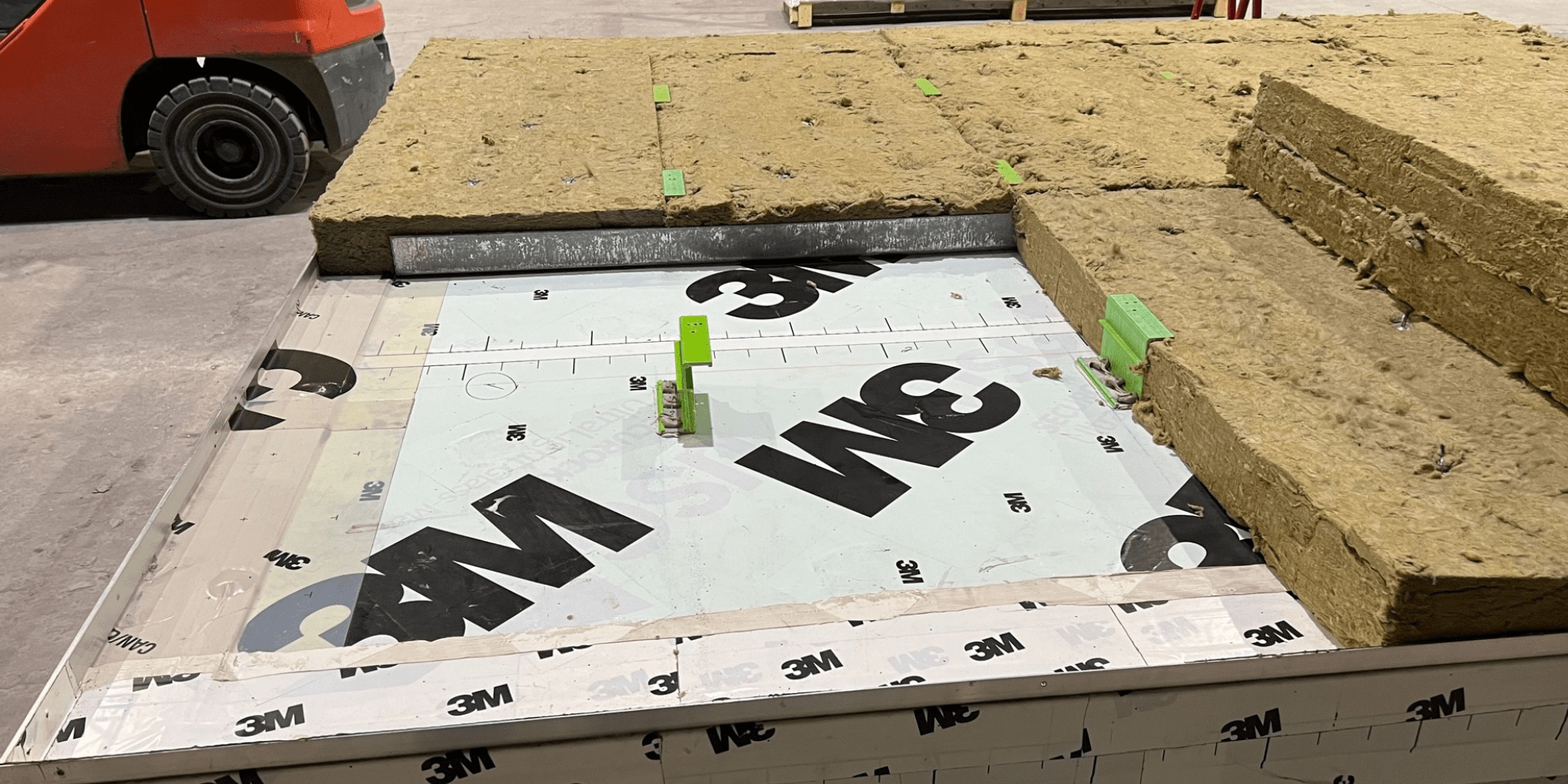

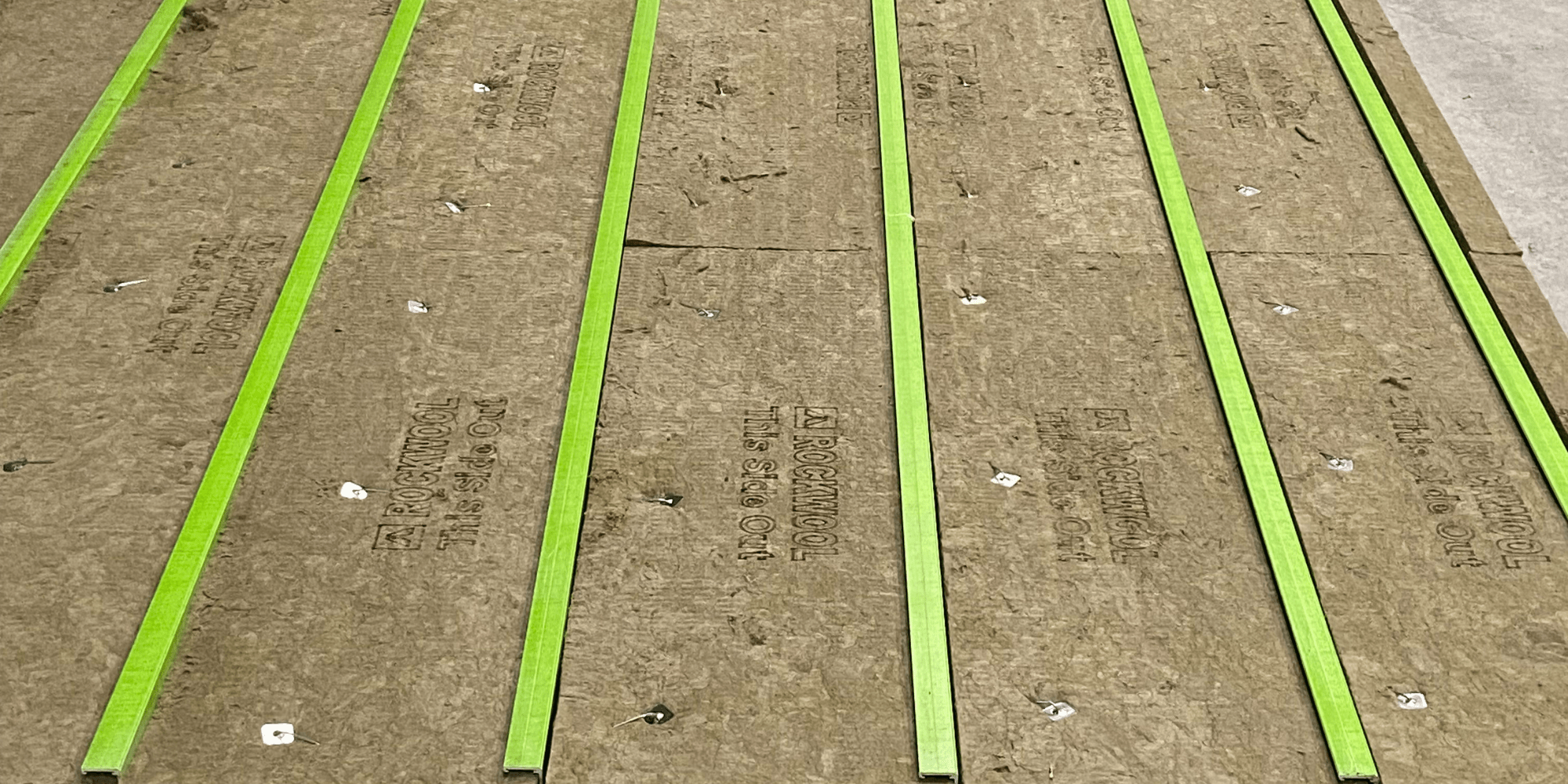

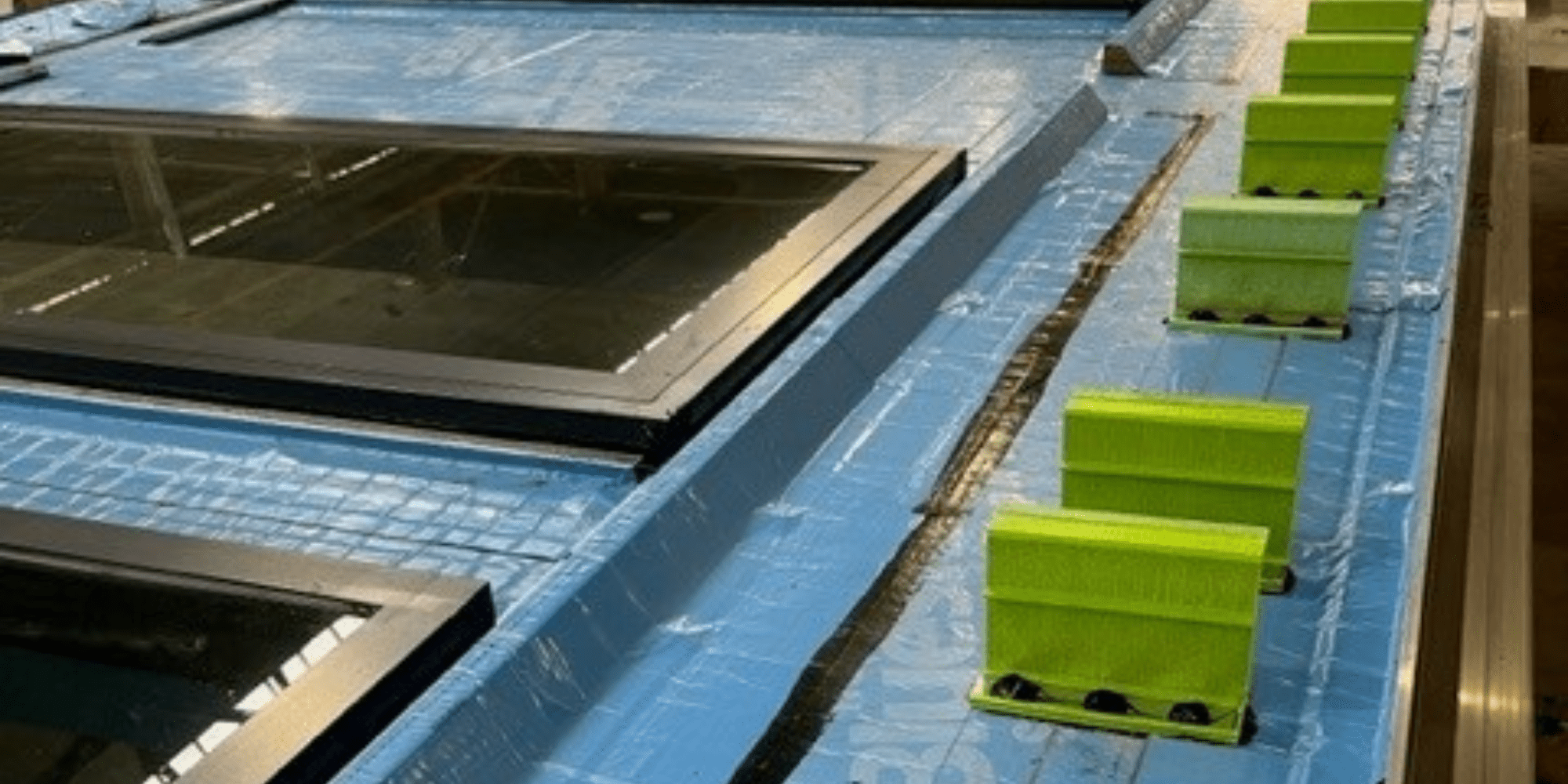

EEWS’s systems are engineered with internal girts to provide proper support for the outboard cladding materials. These girts can be fabricated from galvanized steel, aluminum, stainless steel, or thermally neutral fiberglass. For example, Smart ci green girts are a thermally neutral girt utilized in our systems to ensure the structural integrity of the panels and meet energy efficiency objectives. Within the insulation, our systems are engineered with internal girts to provide proper support for the outboard cladding materials. These girts can be fabricated from galvanized steel, aluminum, stainless steel, or thermally neutral fiberglass. For example, Smart ci green girts are a thermally neutral girt utilized in our systems to ensure the structural integrity of the panels and meet energy efficiency objectives.

Need Fabrication Design Services?

Need something custom for your fabrication project? Contact us to discuss your project details.

Girt Integration & Support

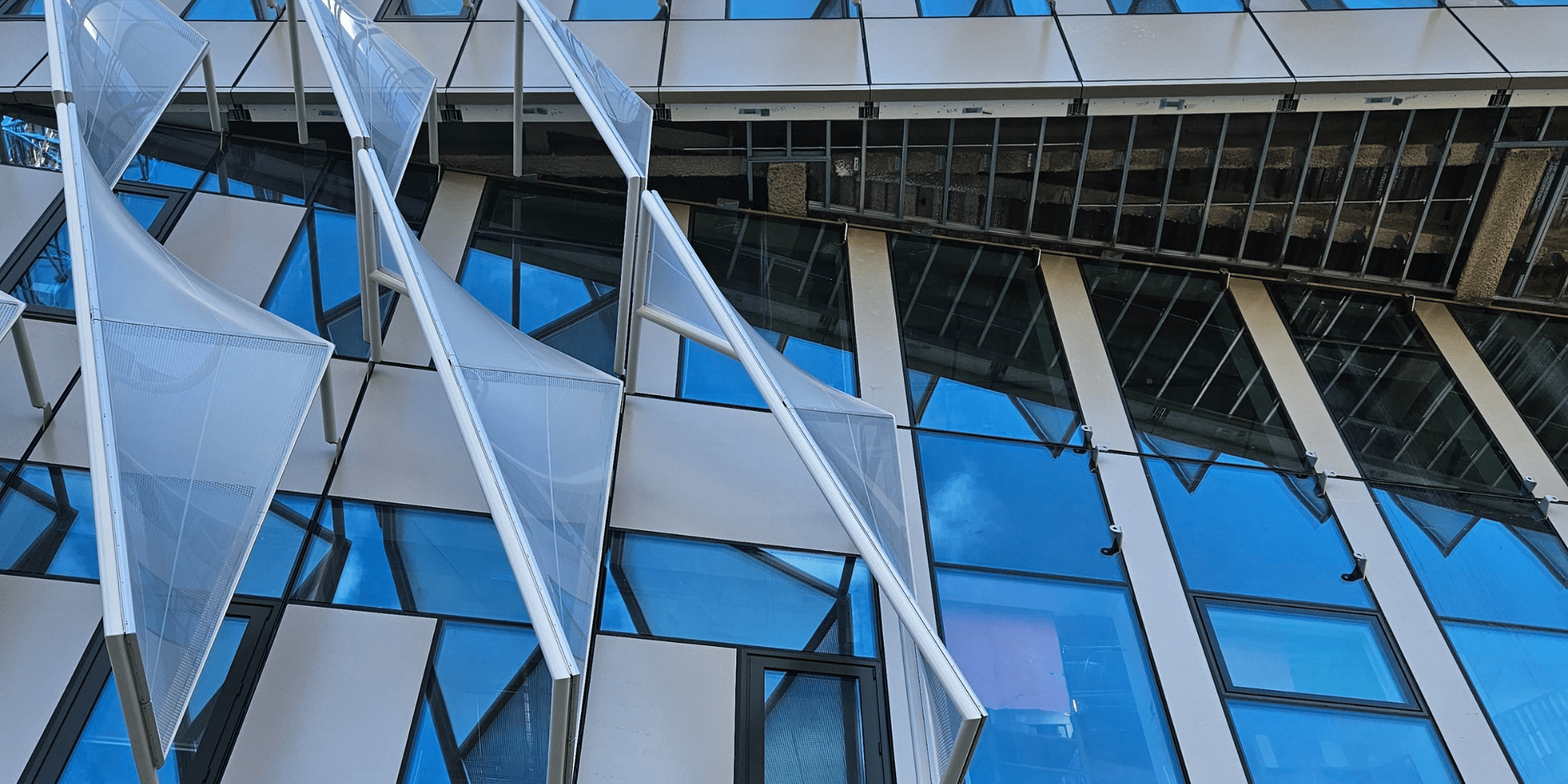

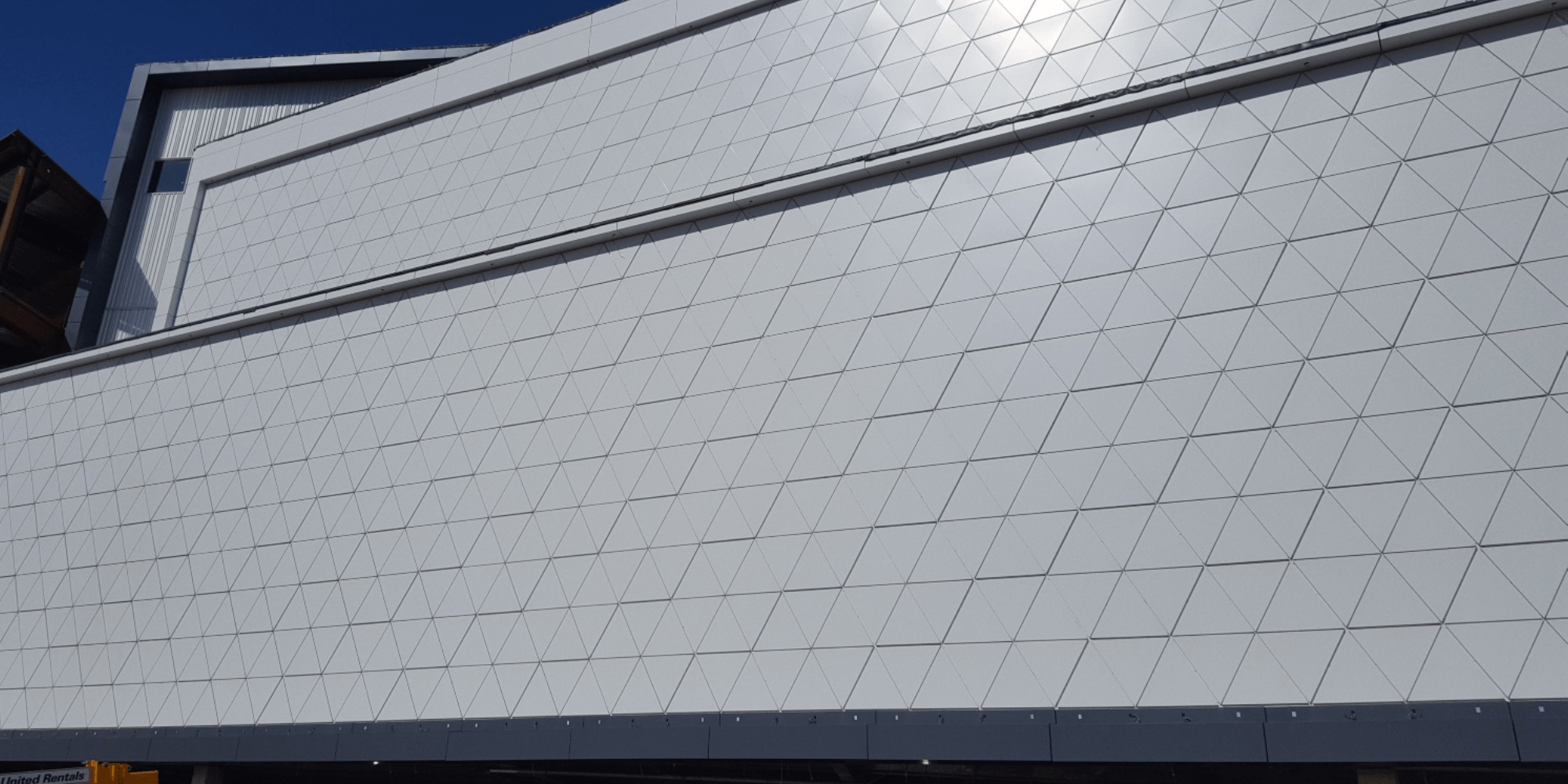

Our panel systems are engineered with an internal girt structure to enhance strength, alignment, and thermal performance. Girts serve as the internal support framework within each panel, creating continuous structural integrity across the system without compromising energy efficiency. Our girt design strategically connects panel joints through the insulation and securely ties them to the building's primary framing. This allows for a fully integrated load path without creating gaps in the thermal barrier, preserving the performance of the insulation and ensuring long-term system durability.

How Girts Work Within Our System

The girts embedded in our panels act as structural bridges between joints, enabling the panelized system to distribute wind loads, dead loads, and thermal movement forces evenly across the façade. They create a direct, reliable connection from the face of the panel through the insulation layer to the building structure behind it. Unlike traditional stick-built systems, where insulation is often interrupted by framing and fasteners, our system maintains continuous insulation (CI). The girts are designed to minimize thermal bridging — meaning they provide support without sacrificing energy performance.

Thermal Efficiency & Performance

Maintaining an uninterrupted thermal barrier is critical for building performance, occupant comfort, and energy savings. Our girt integration is specifically engineered to support structural loads while preserving the panel's continuous insulation. Key benefits include:

- Minimized Thermal Bridging: Girts penetrate insulation strategically without creating significant energy leaks.

- Maintained R-Values: Continuous insulation performance is preserved across the entire wall system.

- Enhanced Air and Moisture Control: By maintaining the insulation layer, our system also strengthens the air and moisture barrier of the building envelope.

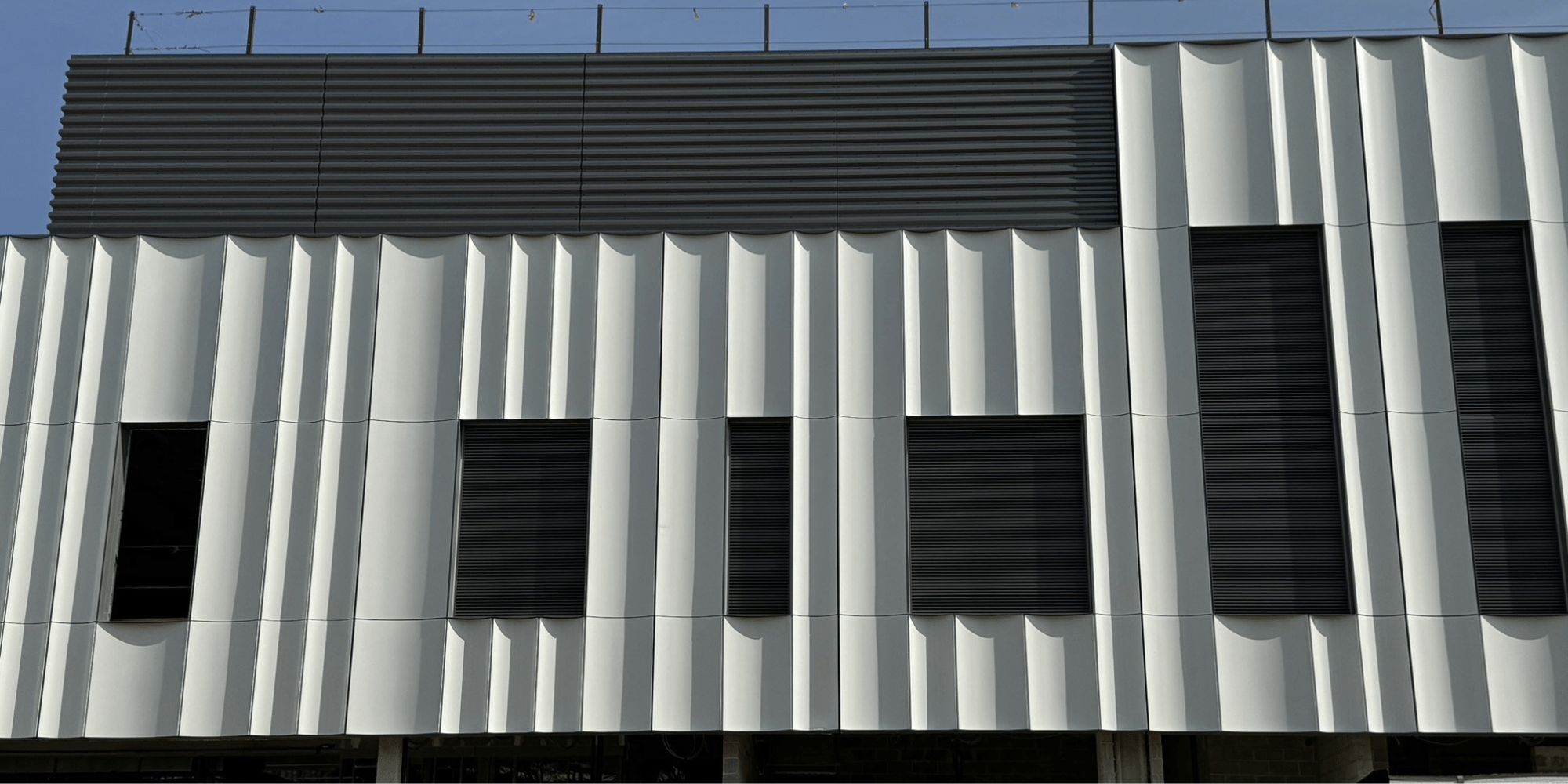

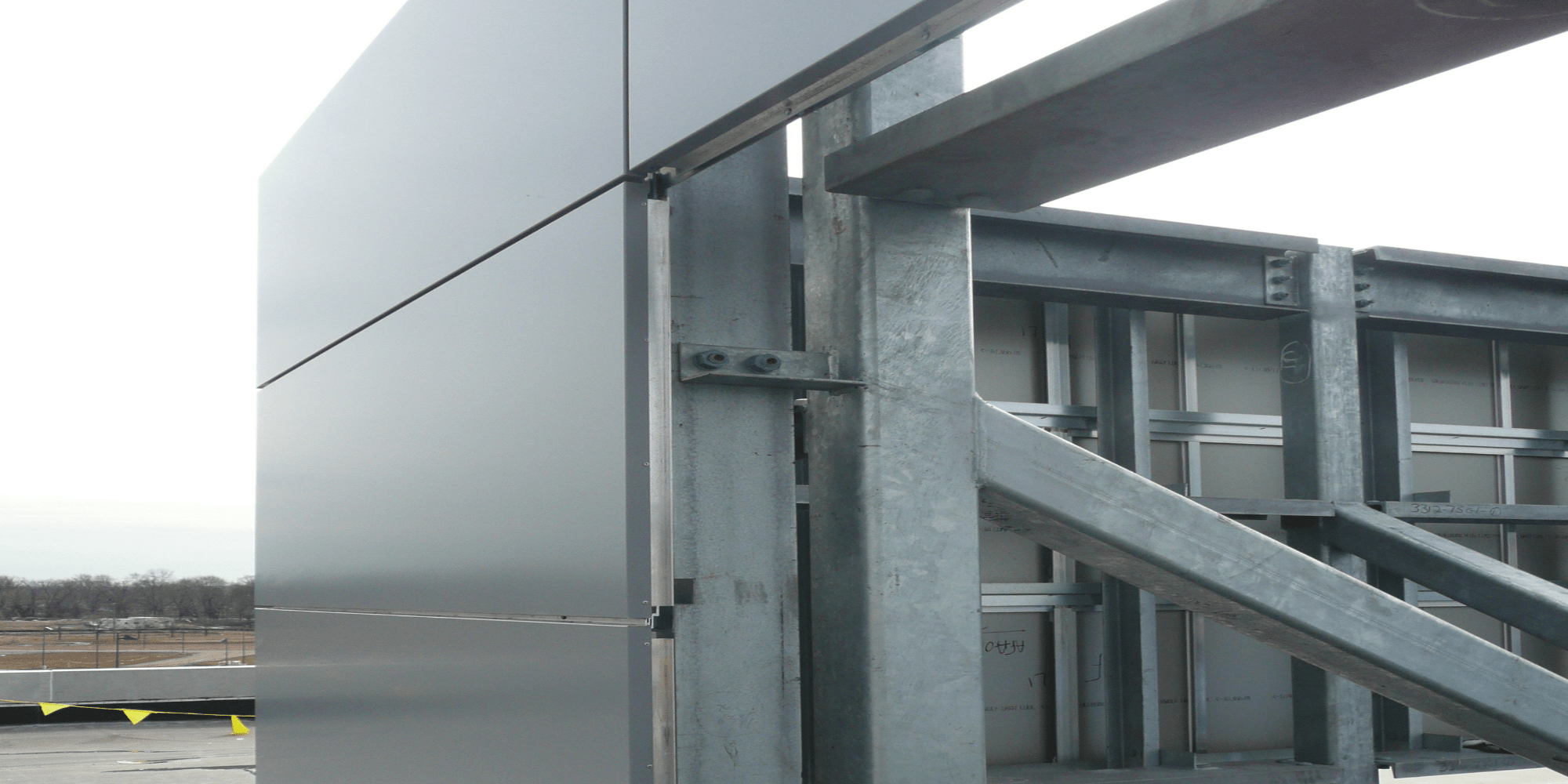

Structural Strength & Alignment

Internal girts also enhance the precision and stability of our panelized wall systems. They allow for:

- Tight and consistent panel alignment at joints and corners

- Controlled movement across expansion joints

- Reliable long-term performance under wind pressure, seismic activity, and building settlement

Fabrication & Quality Control

Girts are fully engineered and integrated during the panel fabrication process in our controlled manufacturing environment. Each component is placed with precision based on project-specific engineering requirements, ensuring consistent performance across every panel installed. Full-scale mockups and testing are conducted to verify structural performance, connection reliability, and the system's ability to maintain thermal protection across all transitions.

FAQ

What are girts in construction?

What are girts in construction?

Girts are horizontal structural members used in wall framing systems to provide lateral support and distribute loads. In panelized wall systems, they are integrated within panels to enhance structural integrity and maintain continuous insulation.

How do integrated girts improve thermal performance?

How do integrated girts improve thermal performance?

Integrated girts minimize thermal bridging by allowing insulation to remain uninterrupted across the wall system. This design preserves the R-value of the insulation, enhancing energy efficiency and occupant comfort.

Why are girts essential for structural alignment?

Why are girts essential for structural alignment?

Girts provide a stable framework that ensures precise panel alignment, especially at joints and corners. They help manage building movements due to wind loads, seismic activity, and thermal expansion, maintaining the façade’s integrity over time.

What materials are commonly used for girts?

What materials are commonly used for girts?

Girts are typically made from galvanized steel or aluminum, chosen for their strength, durability, and resistance to corrosion. The material selection depends on the specific requirements of the building project.

Can girts be customized for specific projects?

Can girts be customized for specific projects?

Yes, girts can be engineered and fabricated to meet the unique structural and thermal requirements of individual projects. Custom Girts ensure optimal performance and integration within the panelized wall system.

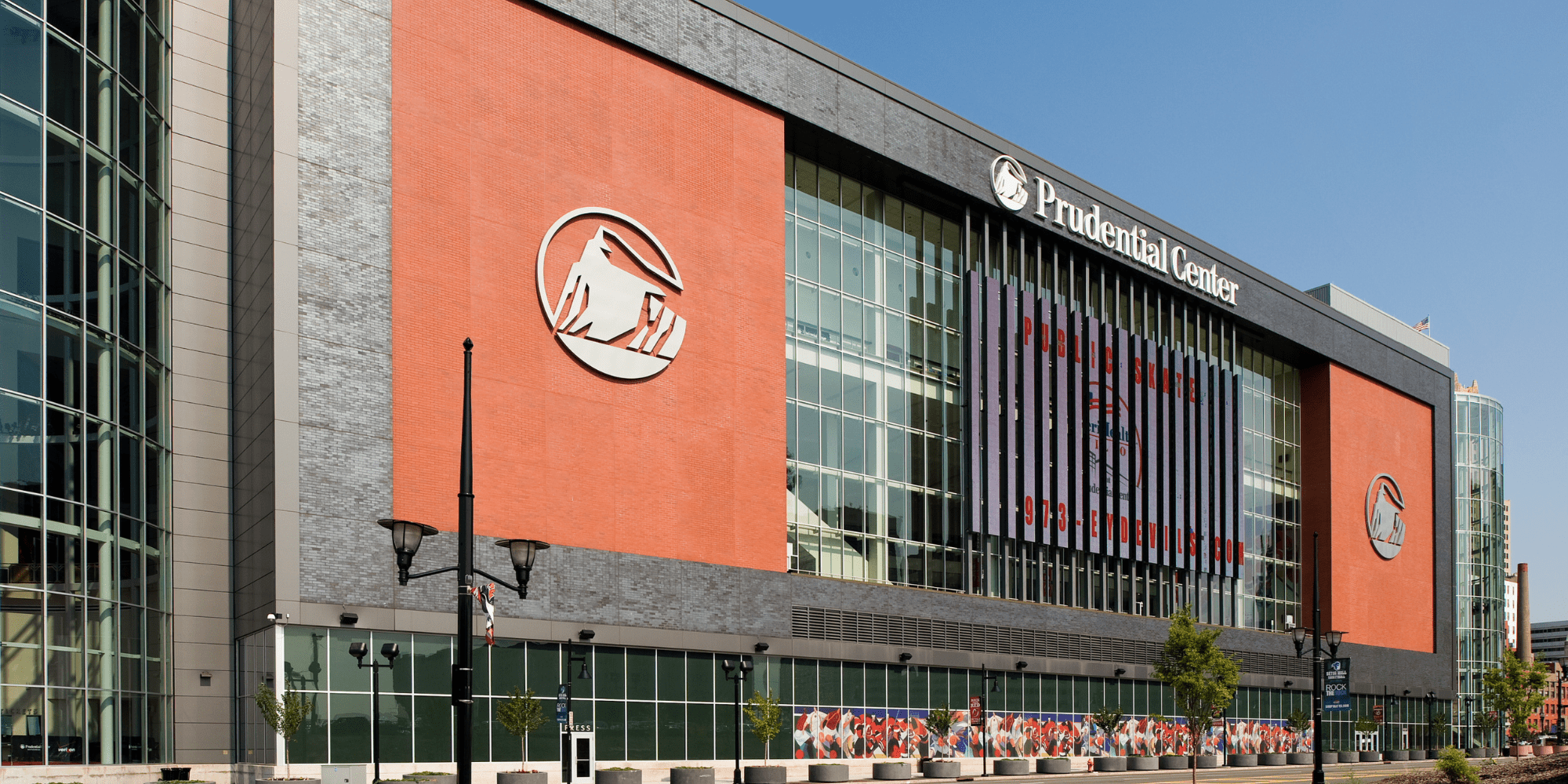

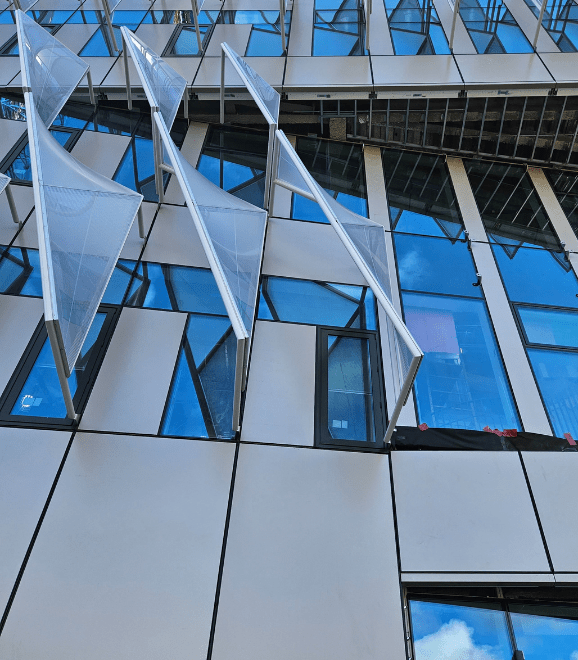

Maximizing The benefits Of Prefabrication

Design Assist

Our collaborative process unites one experienced team from design through installation. In-house Revit-certified designers ensure every detail is carefully planned and executed. Early alignment on goals and continuous design and budget feedback keep projects on track. This streamlined approach eliminates inefficiencies and delivers reliable, high-quality results.

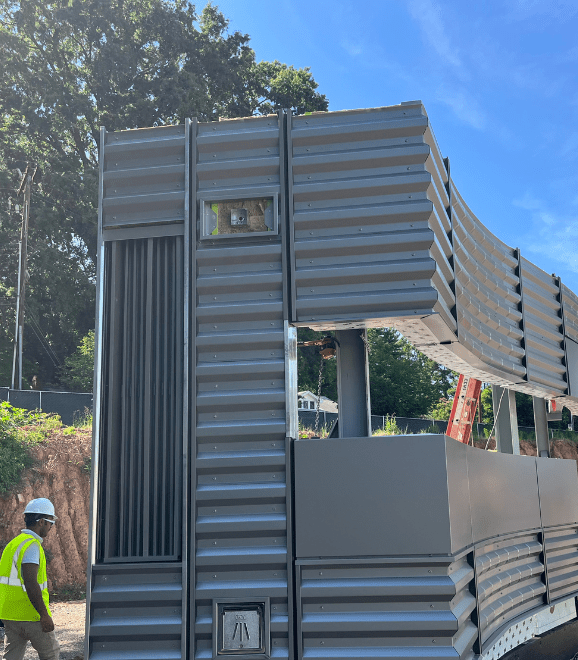

Safer Job Site

Our panelized enclosure system reduces on-site labor and shortens the project timeline, cutting labor costs. Pre-engineered and assembled off-site, it eliminates material storage, site congestion, and waste. Fewer trades are needed on-site, creating a cleaner, safer work environment. This streamlined process also lowers the risk of accidents and boosts site efficiency.

Quality Assurance

Our panelized systems provide superior thermal, moisture, and air performance through a continuous, high-quality enclosure. Assembled in a controlled facility, components like AVB, windows, and louvers are installed with precision. A single expert team handles multiple trades, reducing gaps and delays. This process also simplifies inspections and ensures consistent quality.

Building Enclosure Speed

Prefabricated panel systems greatly speed up the building enclosure process. Off-site fabrication in a controlled environment allows for faster dry-in and earlier interior work. This reduces weather delays and shortens the overall schedule. It’s an ideal solution for projects with tight timelines or phased occupancy.

Coordinated Engineered Interfaces Solutions

Our system features fully coordinated, engineered interfaces for seamless integration of all enclosure components. Key details are resolved during design and fabrication, avoiding on-site conflicts. This approach minimizes field adjustments and ensures consistent quality. The result is a unified, high-performing building envelope from day one.

Logistics

Prefabricated enclosure systems streamline logistics by reducing the volume of material delivered to and stored on-site. With just-in-time delivery and panels arriving in sequence, site congestion, waste, and handling are minimized. This controlled flow of materials supports cleaner, safer job sites and simplifies coordination among trades. The result is a more efficient, organized construction process that aligns with modern lean building practices.

Thermal Performance

When design allows, increasing opaque wall areas with prefabricated systems can greatly improve thermal performance. Fewer unitized joints enhance energy efficiency and air-tightness. These systems also offer broad cladding flexibility, giving architects more design freedom. In this case, the prefabricated enclosure is over four times more energy efficient than a traditional glass curtain wall.

Need Fabrication Services?

Need something custom for your fabrication project? Contact us to discuss your project details.

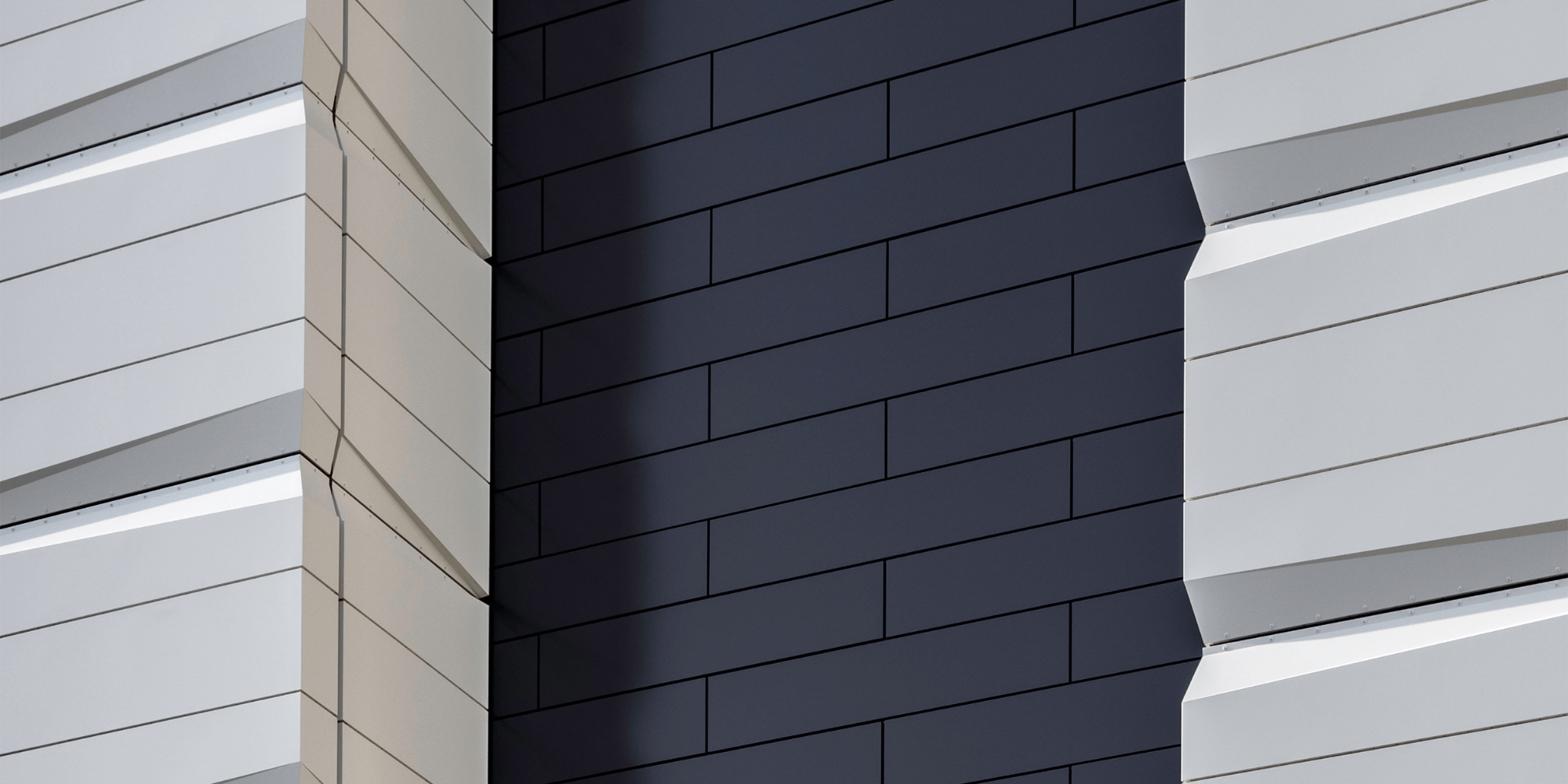

Material Options

From cladding, to integration, and components.