What Is Prefabrication?

Prefabrication

Prefabrication is the process of designing, engineering, and manufacturing exterior wall systems in a controlled facility — before they reach the construction site.

Assembly

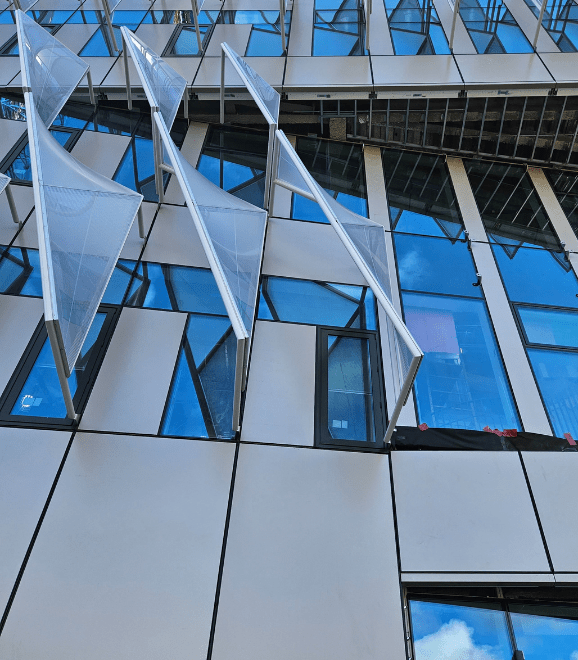

From structural framing to final cladding, every element is pre-assembled into large “mega panels,” complete with rainscreen or barrier systems and dry gasket or wet-sealed joints.

Enclosure

Once the panels are installed, the building’s enclosure is complete (or nearly complete), saving time, improving quality, and reducing on-site risks.

During the Prefabrication Process EEWS:

Safer Job Site

Our panelized enclosure system reduces on-site labor and shortens the project timeline, cutting labor costs. Pre-engineered and assembled off-site, it eliminates material storage, site congestion, and waste. Fewer trades are needed on-site, creating a cleaner, safer work environment. This streamlined process also lowers the risk of accidents and boosts site efficiency. Fewer people working at height means safer conditions. Less material clutter, easier crane operations, and cleaner installations.

Quality Assurance

Our panelized systems provide superior thermal, moisture, and air performance through a continuous, high-quality enclosure. Assembled in a controlled facility, components like AVB, windows, and louvers are installed with precision. A single expert team handles multiple trades, reducing gaps and delays. This process also simplifies inspections and ensures consistent quality. Everything is built in a climate-controlled environment for better consistency & precision.

Building Enclosure Speed

Prefabricated panel systems greatly speed up the building enclosure process. Off-site fabrication in a controlled environment allows for faster dry-in and earlier interior work. This reduces weather delays and shortens the overall schedule. It’s an ideal solution for projects with tight timelines or phased occupancy.

Coordinated Engineered Interfaces Solutions

Our system features fully coordinated, engineered interfaces for seamless integration of all enclosure components. Key details are resolved during design and fabrication, avoiding on-site conflicts. This approach minimizes field adjustments and ensures consistent quality. The result is a unified, high-performing building envelope from day one.

Logistics

Prefabricated enclosure systems streamline logistics by reducing the volume of material delivered to and stored on-site. With just-in-time delivery and panels arriving in sequence, site congestion, waste, and handling are minimized. This controlled flow of materials supports cleaner, safer job sites and simplifies coordination among trades. The result is a more efficient, organized construction process that aligns with modern lean building practices.

Thermal Performance

When design allows, increasing opaque wall areas with prefabricated systems can greatly improve thermal performance. Fewer unitized joints enhance energy efficiency and air-tightness. These systems also offer broad cladding flexibility, giving architects more design freedom. In this case, the prefabricated enclosure is over four times more energy efficient than a traditional glass curtain wall.

Mockups and Testing

Before full-scale production, we build and test mockups of Exterior Wall Panels and Exterior Wall Systems to verify performance. These controlled tests evaluate air, water, and structural resilience, ensuring both Exterior Wall Panel Prefabrication and Exterior Wall Systems Fabrication meet or exceed project standards. This guarantees quality assurance and identifies potential improvements before manufacturing begins. All window and glazing integrations are engineered in-house by our experienced design team, ensuring compatibility with the overall wall panel system. We perform rigorous testing on full-scale mockups, including water penetration testing, structural load testing, and thermal performance evaluations, to verify the system’s reliability before full production. Our goal is to deliver an integrated façade solution where glazing and wall panels perform as a unified, high-performance system — not as separate components.

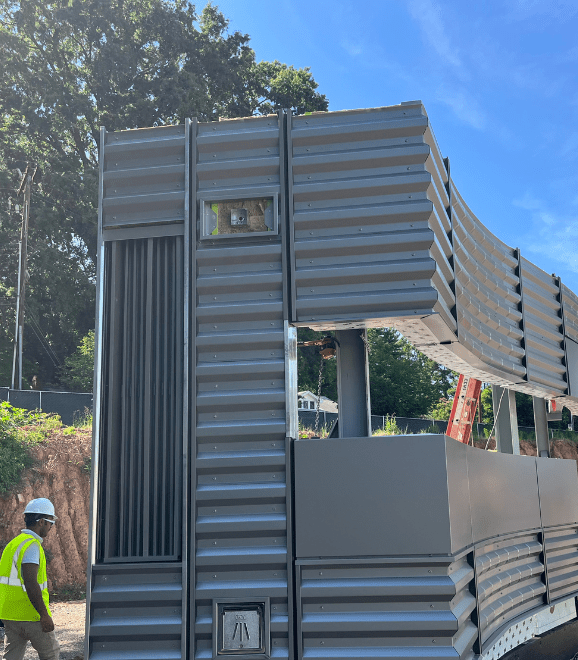

Delivery & Installation

Once manufactured, Exterior Wall Panels and Exterior Wall Systems are delivered ready for immediate installation. This approach eliminates excess material handling and accelerates enclosure timelines. Exterior Wall Panel Manufacturers and Exterior Wall Systems Fabrication teams coordinate logistics to streamline crane operations and reduce disruptions, making the overall process faster, safer, and more efficient for field crews and project managers alike.

Mockups and Testing

Before full-scale production, we build and test mockups of Exterior Wall Panels and Exterior Wall Systems to verify performance. These controlled tests evaluate air, water, and structural resilience, ensuring both Exterior Wall Panel Prefabrication and Exterior Wall Systems Fabrication meet or exceed project standards. This guarantees quality assurance and identifies potential improvements before manufacturing begins. All window and glazing integrations are engineered in-house by our experienced design team, ensuring compatibility with the overall wall panel system. We perform rigorous testing on full-scale mockups, including water penetration testing, structural load testing, and thermal performance evaluations, to verify the system’s reliability before full production. Our goal is to deliver an integrated façade solution where glazing and wall panels perform as a unified, high-performance system — not as separate components.

Delivery & Installation

Once manufactured, Exterior Wall Panels and Exterior Wall Systems are delivered ready for immediate installation. This approach eliminates excess material handling and accelerates enclosure timelines. Exterior Wall Panel Manufacturers and Exterior Wall Systems Fabrication teams coordinate logistics to streamline crane operations and reduce disruptions, making the overall process faster, safer, and more efficient for field crews and project managers alike.

Contact Us To Learn More

Need something custom for your fabrication project? Contact us to discuss your project details.

FAQ

Frequently asked questions asked by our clients regarding our fabrication services.

What are prefabricated exterior wall systems?

What are prefabricated exterior wall systems?

Prefabricated exterior wall systems are complete building envelope solutions manufactured off-site. They integrate elements like cladding, insulation, framing, and windows into large panels, facilitating faster installation and improved quality control.

How does EEWS ensure quality in its fabrication process?

How does EEWS ensure quality in its fabrication process?

EEWS conducts fabrication in climate-controlled facilities, utilizing precision engineering and advanced manufacturing techniques. This controlled environment ensures consistent quality, precise tolerances, and adherence to design specifications.

What materials are commonly used in EEWS's prefabricated panels?

What materials are commonly used in EEWS's prefabricated panels?

EEWS’s panels incorporate materials such as Aluminum Composite Material (ACM), aluminum plate, profiled metal, thin brick, and terra cotta. These materials are chosen for their durability, aesthetic appeal, and compatibility with prefabrication methods.

What are the benefits of using prefabricated wall systems in construction?

What are the benefits of using prefabricated wall systems in construction?

Prefabricated wall systems offer several advantages, including reduced on-site labor, faster installation, enhanced quality control, and improved safety. They also minimize weather-related delays and can lead to cost savings over traditional construction methods.

Can EEWS's prefabricated panels be customized for specific architectural designs?

Can EEWS's prefabricated panels be customized for specific architectural designs?

Yes, EEWS offers customization options for its prefabricated panels, allowing for various cladding materials, colors, textures, and integration of elements like windows and louvers. This flexibility enables architects to achieve their desired aesthetic and functional goals.

Maximizing The benefits Of Prefabrication

Design Assist

Our collaborative process unites one experienced team from design through installation. In-house Revit-certified designers ensure every detail is carefully planned and executed. Early alignment on goals and continuous design and budget feedback keep projects on track. This streamlined approach eliminates inefficiencies and delivers reliable, high-quality results.

Safer Job Site

Our panelized enclosure system reduces on-site labor and shortens the project timeline, cutting labor costs. Pre-engineered and assembled off-site, it eliminates material storage, site congestion, and waste. Fewer trades are needed on-site, creating a cleaner, safer work environment. This streamlined process also lowers the risk of accidents and boosts site efficiency.

Quality Assurance

Our panelized systems provide superior thermal, moisture, and air performance through a continuous, high-quality enclosure. Assembled in a controlled facility, components like AVB, windows, and louvers are installed with precision. A single expert team handles multiple trades, reducing gaps and delays. This process also simplifies inspections and ensures consistent quality.

Building Enclosure Speed

Prefabricated panel systems greatly speed up the building enclosure process. Off-site fabrication in a controlled environment allows for faster dry-in and earlier interior work. This reduces weather delays and shortens the overall schedule. It’s an ideal solution for projects with tight timelines or phased occupancy.

Coordinated Engineered Interfaces Solutions

Our system features fully coordinated, engineered interfaces for seamless integration of all enclosure components. Key details are resolved during design and fabrication, avoiding on-site conflicts. This approach minimizes field adjustments and ensures consistent quality. The result is a unified, high-performing building envelope from day one.

Logistics

Prefabricated enclosure systems streamline logistics by reducing the volume of material delivered to and stored on-site. With just-in-time delivery and panels arriving in sequence, site congestion, waste, and handling are minimized. This controlled flow of materials supports cleaner, safer job sites and simplifies coordination among trades. The result is a more efficient, organized construction process that aligns with modern lean building practices.

Thermal Performance

When design allows, increasing opaque wall areas with prefabricated systems can greatly improve thermal performance. Fewer unitized joints enhance energy efficiency and air-tightness. These systems also offer broad cladding flexibility, giving architects more design freedom. In this case, the prefabricated enclosure is over four times more energy efficient than a traditional glass curtain wall.