The Energy Efficiency Imperative

Buildings account for nearly 40% of global energy consumption and associated carbon emissions. As a result, national and international energy codes—such as IECC, ASHRAE 90.1, and Title 24—are evolving to demand better thermal performance from building envelopes. That’s where exterior wall panel insulation becomes a game changer.

By providing a continuous barrier against heat loss or gain, insulation within exterior wall panels helps stabilize interior temperatures and reduce HVAC loads. This is especially vital in climates with extreme temperature variations, where heating and cooling systems can account for more than half of a building’s energy usage.

Why Prefabricated Exterior Wall Systems Lead the Way

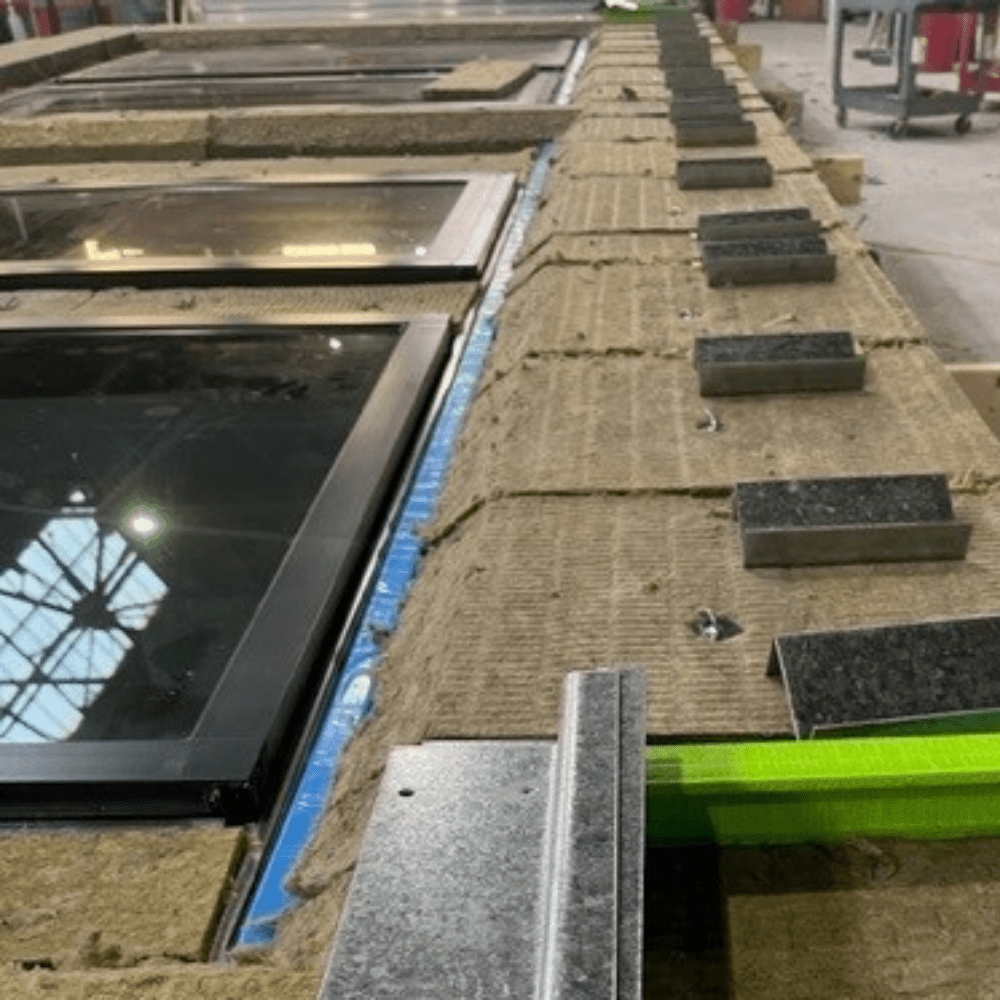

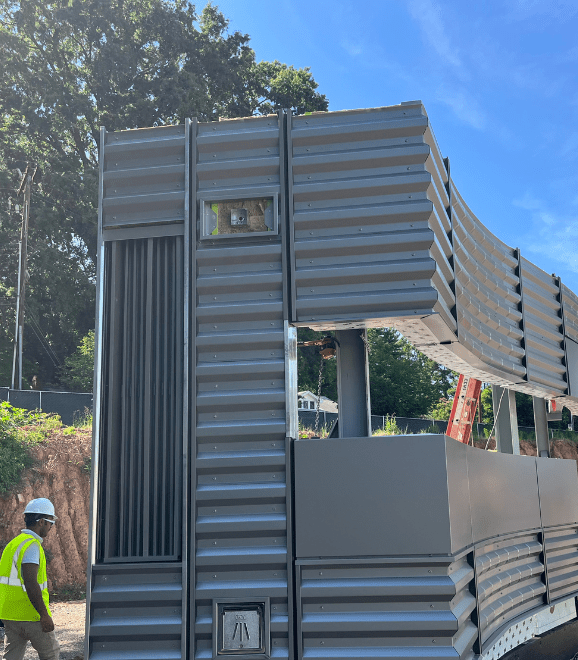

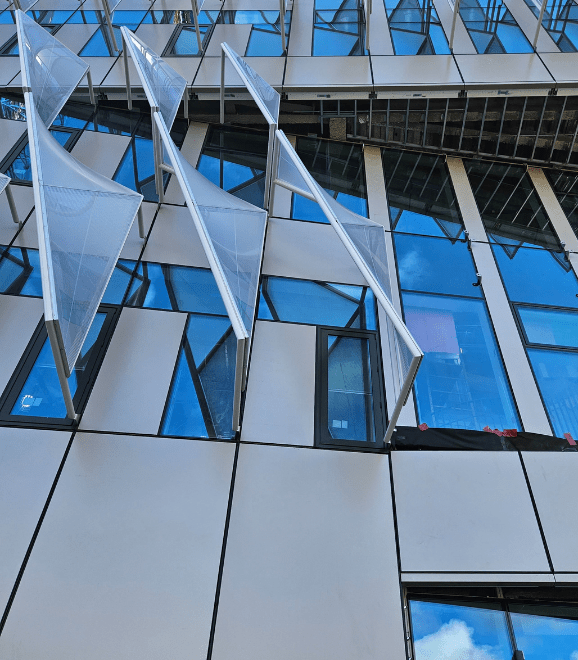

Traditional stick-built wall systems often involve multiple layers assembled on-site under varying conditions, increasing the risk of thermal bridging, inconsistent installation, and air leakage. In contrast, prefabricated exterior wall systems offer an integrated solution. These panels are manufactured in controlled factory settings, ensuring precision, quality, and performance.

By incorporating exterior wall panel insulation into the prefab process, manufacturers can optimize the thermal design of each panel—minimizing thermal breaks and achieving continuous insulation without gaps. This translates into walls that not only meet but often exceed modern energy code requirements.

Key Benefits of Exterior Wall Panel Insulation in Prefab Systems

- Thermal Performance

Continuous insulation within prefab panels eliminates the interruptions caused by studs and framing, which act as thermal bridges in conventional wall assemblies. This reduces energy loss and increases the effective R-value of the wall system. - Speed and Efficiency

Since insulation is integrated into the panel during manufacturing, there’s no need for additional onsite installation. This speeds up construction timelines and reduces labor costs, making prefabricated exterior wall systems an attractive option for developers and contractors. - Quality Control

Factory-installed exterior wall panel insulation ensures consistency in material placement, thickness, and coverage—factors that are hard to control in field installations. - Code Compliance

With pre-tested and certified assemblies, meeting or exceeding energy code requirements becomes simpler. Prefab panels often come with documentation to support code inspections and energy modeling.

Comparing Common Insulation Materials

Not all exterior wall panel insulation is created equal. The choice of insulation material impacts thermal performance, fire resistance, cost, and environmental footprint. Here’s a closer look at the most common options used in prefabricated exterior wall systems.

1. Polyisocyanurate (Polyiso) Foam

Thermal Performance: High (R-6.0 to R-6.5 per inch)

Fire Resistance: Good (with foil or fiberglass facers)

Cost: Moderate to High

Polyiso is one of the most efficient rigid foam boards in terms of thermal resistance per inch. It is often used in commercial wall systems due to its thin profile and excellent insulating properties. It performs well in moderate to hot climates and is commonly integrated into curtain wall and rainscreen assemblies.

Best for: Projects needing high R-values in limited wall depths.

2. Extruded Polystyrene (XPS)

Thermal Performance: Moderate to High (R-5 per inch)

Fire Resistance: Moderate

Cost: Moderate

XPS foam is known for its moisture resistance and compressive strength, making it suitable for a variety of exterior applications. However, it must be carefully detailed to meet fire code requirements, especially in multi-story applications.

Best for: Wall systems in humid or freeze-thaw environments.

3. Mineral Wool (Stone Wool)

Thermal Performance: Moderate (R-4.2 per inch)

Fire Resistance: Excellent (non-combustible)

Cost: Moderate

Mineral wool is a high-performance insulation known for its fire resistance and acoustic performance. It’s ideal for buildings that require non-combustible materials, such as hospitals, schools, and high-rise towers.

Best for: Fire-rated wall assemblies and sound-sensitive environments.

4. Expanded Polystyrene (EPS)

Thermal Performance: Moderate (R-3.6 to R-4.2 per inch)

Fire Resistance: Lower (must be covered)

Cost: Low

EPS is an economical insulation option that offers good thermal performance. However, it is more vapor-permeable and less fire-resistant than other foams, making it less suitable for some commercial applications.

Best for: Low-rise residential projects with budget constraints.

Design Considerations for Maximum Efficiency

When integrating exterior wall panel insulation into your building design, several key factors should be considered:

1. Continuous Insulation

To minimize thermal bridging, insulation should wrap the entire exterior envelope with minimal interruptions. Prefabricated exterior wall systems are ideal for this purpose, as they can incorporate continuous layers of foam or mineral wool between framing elements.

2. Thermal Bridging Mitigation

Metal studs and structural connections can transmit heat across the wall system. Look for systems that use thermal breaks, non-conductive clips, or double-stud framing to isolate cold and warm surfaces.

3. Air and Vapor Control

Energy efficiency isn’t just about R-values. Air infiltration and moisture intrusion can significantly degrade insulation performance. Many prefabricated exterior wall systems include integrated air and vapor barriers to enhance building envelope tightness.

4. Assembly U-Factor

Instead of just focusing on R-value, consider the U-factor of the entire wall assembly, which accounts for framing, insulation, and cladding layers. This gives a more accurate picture of thermal performance in real-world conditions.

Meeting and Exceeding Energy Codes

Modern codes are pushing buildings to achieve net-zero or near-zero energy status. Using exterior wall panel insulation effectively in prefab systems is a smart way to meet—or even exceed—requirements from:

- IECC (International Energy Conservation Code)

- ASHRAE 90.1 (commercial energy standard)

- LEED (Leadership in Energy and Environmental Design)

- Passive House standards

Integrating high-performance insulation early in the design process not only streamlines approvals but also positions the project for long-term energy savings and improved indoor comfort.

Conclusion

In a construction environment that demands energy efficiency, durability, and cost-effectiveness, exterior wall panel insulation has never been more important. When combined with prefabricated exterior wall systems, it offers a powerful solution for developers, architects, and contractors seeking to build high-performance, code-compliant structures with greater speed and reliability.

By choosing the right insulation material and designing for continuous thermal performance, you can reduce energy consumption, lower operational costs, and contribute to a more sustainable built environment.

The path to better buildings starts in the walls—and with the right exterior wall panel insulation, your next project can lead the way.