The Rise of Prefabricated Exterior Wall Systems

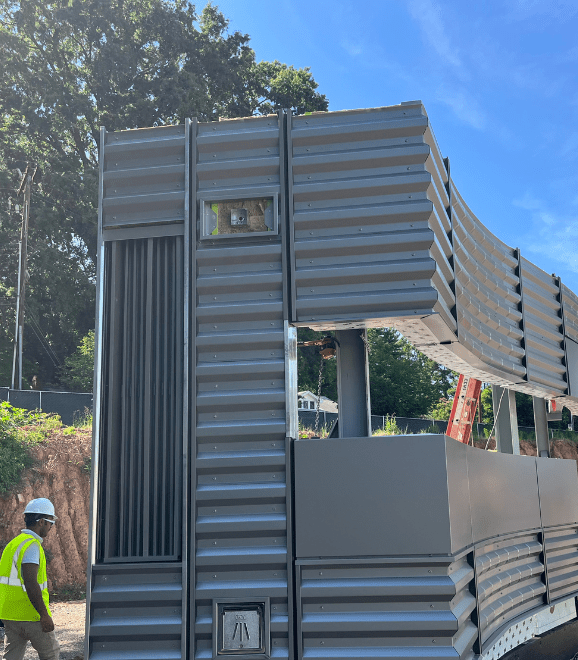

Prefabrication isn’t a new concept, but its integration into mainstream construction has gained significant momentum over the past decade. Prefabricated exterior wall systems are pre-engineered, pre-assembled wall units that are manufactured in a controlled factory environment before being transported to the job site for rapid installation. This approach eliminates many of the inefficiencies and delays associated with traditional, site-built wall construction.

The advantages are compelling: reduced labor costs, faster project delivery, minimized site disruption, and improved quality control. As construction timelines tighten and labor shortages persist, prefabricated exterior wall systems offer a scalable solution for developers aiming to deliver projects on time and within budget.

Efficiency Gains Through Advanced Manufacturing

One of the greatest benefits of prefabricated exterior wall systems is the significant boost in efficiency they provide. Manufacturing wall components off-site under controlled conditions allows for precision and consistency that is difficult to achieve in field conditions. Each wall panel can be customized to include windows, doors, air and water barriers, exterior wall panel insulation, and exterior wall panel cladding materials—all installed with factory-level accuracy.

Once delivered to the site, these panels can be quickly assembled like puzzle pieces, drastically reducing on-site labor time and weather-related delays. This streamlined process shortens the construction timeline, which is especially valuable for large-scale commercial or multifamily developments where time is money.

Sustainability at the Core

Beyond speed and cost savings, prefabricated exterior wall systems contribute meaningfully to sustainability goals. Waste reduction is one of the most notable advantages. Traditional construction often results in significant material waste due to onsite cutting and handling. In contrast, prefabricated systems generate far less waste, thanks to optimized material usage and recycling practices in factory settings.

Additionally, exterior wall panel insulation plays a vital role in enhancing a building’s energy efficiency. By integrating high-performance insulation into the panel during the manufacturing process, thermal bridging is minimized, and energy loss is reduced. This leads to lower heating and cooling loads, reduced operational costs, and improved occupant comfort.

The use of innovative exterior wall panel cladding materials—such as fiber cement, metal composites, terra cotta, or high-pressure laminates—further supports environmental performance. Many of these materials are not only durable and low-maintenance but also recyclable and available with environmentally responsible certifications.

Innovations in Materials and Design

Material science and digital design are pushing the boundaries of what prefabricated exterior wall systems can achieve. With the help of BIM (Building Information Modeling), design teams can model complex wall systems in 3D, allowing for precise integration of mechanical systems, exterior wall panel insulation, and cladding details. This results in fewer design conflicts and ensures that what is manufactured is exactly what is needed.

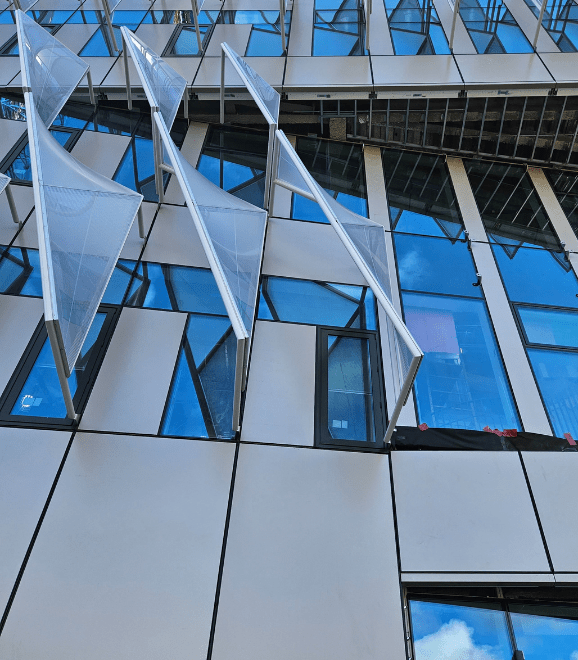

Advances in exterior wall panel cladding materials are also expanding aesthetic and functional possibilities. Architects are no longer limited to a one-size-fits-all solution. Instead, they can select from a wide variety of textures, colors, and performance attributes that align with the project’s design intent and environmental requirements.

Moreover, some manufacturers are now offering wall panels with integrated photovoltaic (PV) systems. These energy-generating facades turn buildings into contributors to the energy grid, enhancing their sustainability profile while potentially qualifying them for green building certifications such as LEED or WELL.

Prefabrication Meets Customization

A common misconception is that prefabrication leads to cookie-cutter designs. However, modern prefabricated exterior wall systems can be tailored to meet virtually any architectural vision. Advanced robotic manufacturing and digital fabrication tools make it possible to create complex geometries and unique facade patterns with ease.

Furthermore, the ability to integrate exterior wall panel insulation and cladding directly into the panel provides additional flexibility. Architects and designers can experiment with hybrid systems that combine materials—like stone and glass or wood and metal—to achieve distinctive, high-performance building envelopes.

This level of customization allows for beautiful, functional designs without sacrificing the efficiency and precision that prefabrication delivers.

Applications Across Sectors

The versatility of prefabricated exterior wall systems makes them ideal for a wide range of building types. From healthcare facilities and educational institutions to hotels, office towers, and mixed-use developments, these systems are being embraced across the construction spectrum.

In healthcare, for example, rapid deployment is often critical. Prefabrication allows for faster construction of patient rooms and critical care units with consistent quality. In residential and commercial high-rises, exterior wall panel insulation ensures that each unit meets modern energy codes and provides long-term value to owners and tenants.

The growing interest in modular construction for affordable housing also benefits from prefabricated wall systems. These panels can be designed to accommodate modular units and stackable structures, helping to address the global housing crisis with speed and sustainability.

Challenges and the Road Ahead

While the benefits of prefabricated exterior wall systems are clear, challenges remain. Transportation logistics, upfront coordination, and the need for early design finalization can present hurdles. Successful implementation requires close collaboration between architects, engineers, contractors, and manufacturers from the earliest stages of design.

Education and industry adoption are also key. As more professionals become familiar with the capabilities of prefabrication, the stigma of “modular monotony” is giving way to enthusiasm for what’s possible when innovation meets intention.

Looking ahead, we can expect to see even greater integration of smart technology, automation, and sustainable design principles in prefabricated exterior wall systems. The continued evolution of exterior wall panel insulation and cladding options will enhance building performance while offering stunning visual results.

Conclusion

The future of construction lies in smarter, faster, and greener solutions—and prefabricated exterior wall systems are leading the charge. By reducing waste, improving energy efficiency, and offering unmatched precision and speed, these systems are redefining how we build.

As exterior wall panel insulation becomes more advanced and exterior wall panel cladding materials more diverse, architects and builders will be empowered to create sustainable, high-performance buildings that meet the needs of today and tomorrow. In this new era of construction, prefabrication is no longer just an option—it’s the future.