1. Aluminum Cladding Panels

Durability: ★★★★★

Aesthetics: ★★★★☆

Cost-Effectiveness: ★★★☆☆

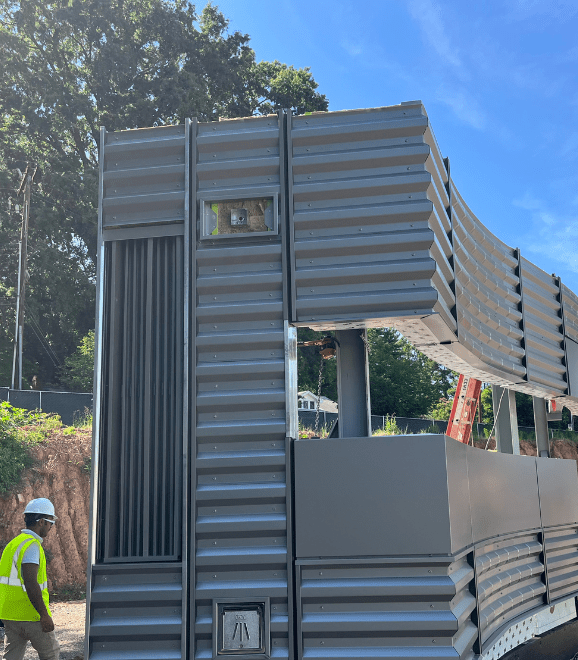

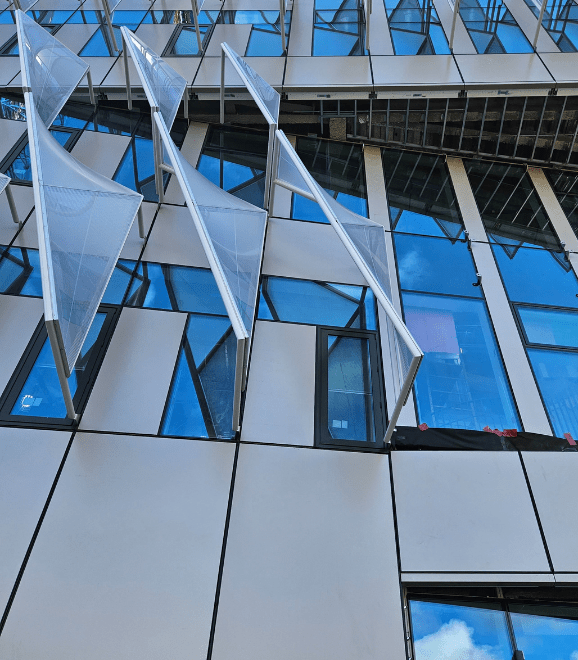

Aluminum is a favorite for many modern architectural projects due to its sleek, contemporary appearance and corrosion resistance. As a lightweight metal, it works exceptionally well in prefabricated exterior wall systems, where structural weight and installation speed are critical considerations.

Advantages:

- Resistant to rust and weather

- Low maintenance and long-lasting

- Recyclable and environmentally friendly

- Excellent for high-rise and commercial applications

Disadvantages:

- Can be more expensive than some alternatives

- May dent or scratch under impact

Aluminum is ideal for buildings seeking a polished, modern look without sacrificing performance, especially in urban and coastal environments.

2. Fiber Cement Panels

Durability: ★★★★☆

Aesthetics: ★★★★☆

Cost-Effectiveness: ★★★★★

Fiber cement has gained popularity due to its balance of durability, affordability, and design flexibility. Composed of cement, sand, and cellulose fibers, it mimics the look of wood, stone, or concrete at a fraction of the cost and maintenance.

Advantages:

- Fire-resistant and non-combustible

- Resistant to insects and moisture

- Offers a wide range of textures and colors

- Very cost-effective for large projects

Disadvantages:

- Heavier than aluminum, requiring stronger framing

- Installation requires dust control due to silica content

In prefabricated exterior wall systems, fiber cement is often chosen for mid-rise buildings and educational or healthcare facilities seeking both visual appeal and long-term performance.

3. Brick Veneer Cladding

Durability: ★★★★★

Aesthetics: ★★★★★

Cost-Effectiveness: ★★★☆☆

Brick veneer combines timeless appeal with proven durability. While traditional masonry is built on-site, prefabricated exterior wall systems allow for brick to be installed in panelized form, significantly reducing construction time and on-site labor.

Advantages:

- Classic appearance with excellent weather resistance

- Low maintenance and extremely durable

- Enhances thermal mass and energy efficiency

Disadvantages:

- Heavier material requiring structural support

- Higher material and labor cost compared to fiber cement

Brick is ideal for institutional or historical buildings, and it adds value to residential projects where a classic finish is preferred.

4. High-Pressure Laminate (HPL) Panels

Durability: ★★★★☆

Aesthetics: ★★★★☆

Cost-Effectiveness: ★★★★☆

HPL panels offer vibrant color choices and textures, making them perfect for design-driven projects. These panels are manufactured under high pressure and temperature, making them resistant to UV rays, scratches, and moisture.

Advantages:

- Vast range of colors and finishes

- Good UV stability for sunny climates

- Lightweight and easy to integrate into prefabricated exterior wall systems

Disadvantages:

- May not be as impact-resistant as metal or cement

- More common in commercial or institutional applications than residential

HPL is an excellent choice when creative freedom is a priority, such as in schools, offices, or public buildings.

5. Natural Stone or Stone Veneer

Durability: ★★★★★

Aesthetics: ★★★★★

Cost-Effectiveness: ★★☆☆☆

Natural stone exudes luxury and permanence. While heavy and expensive, stone veneer panels allow for a similar aesthetic at a reduced weight and cost—making them suitable for prefabricated exterior wall systems without overloading the structure.

Advantages:

- Timeless, high-end appearance

- Extremely weather and fire-resistant

- Adds property value and curb appeal

Disadvantages:

- Higher cost and longer lead times

- Requires reinforced structural framing

Stone is often used for landmark buildings, luxury properties, or mixed-use developments looking to convey permanence and prestige.

Key Considerations When Choosing Cladding

To make the right choice, you’ll need to weigh several factors that go beyond appearance:

1. Climate Compatibility

Weather plays a huge role in determining which exterior wall panel cladding materials will perform best. For example, fiber cement and brick veneer perform well in humid and storm-prone climates, while aluminum is ideal for salt-laden coastal environments.

2. Maintenance Requirements

How much upkeep are you or your client willing to handle? Materials like aluminum and fiber cement require minimal maintenance, while natural stone may need occasional sealing or inspection.

3. Budget Constraints

Project budgets can vary widely. While some clients might prefer premium stone or custom metals, fiber cement or HPL can offer an attractive alternative at a lower cost.

4. Architectural Intent

Do you want a contemporary finish or a traditional look? Some materials lend themselves to minimalist, modern styles, while others are better suited to heritage or institutional buildings.

5. Integration with Prefabricated Systems

Not all materials are equally compatible with prefabricated exterior wall systems. Lightweight, durable materials with standardized sizes and mounting systems often simplify off-site panelization and reduce labor on site.

Final Thoughts

Choosing the right exterior wall panel cladding materials is a critical decision that affects everything from aesthetics and cost to performance and sustainability. With the increasing use of prefabricated exterior wall systems, this choice must be made early and in alignment with manufacturing capabilities.

Each cladding option—whether it’s aluminum, fiber cement, brick, HPL, or stone—has its strengths and ideal applications. By understanding the unique characteristics of each, you can match your material choice with your project’s goals, ensuring a beautiful, durable, and efficient building envelope.

In the end, the best material isn’t just the most attractive—it’s the one that meets your budget, complements your design, performs under environmental stress, and integrates seamlessly into your construction timeline. When all these pieces align, your exterior wall system becomes more than just a skin—it becomes a smart investment in your project’s long-term success.