1. Panel Misalignment

The Challenge:

One of the most common and visible problems during exterior wall panel installation is misalignment. Poor panel positioning leads to uneven joint lines, inconsistent reveals, and an unprofessional appearance. But beyond aesthetics, misalignment can also cause stress on fasteners and compromise structural stability.

Causes:

- Inaccurate layout or measurement

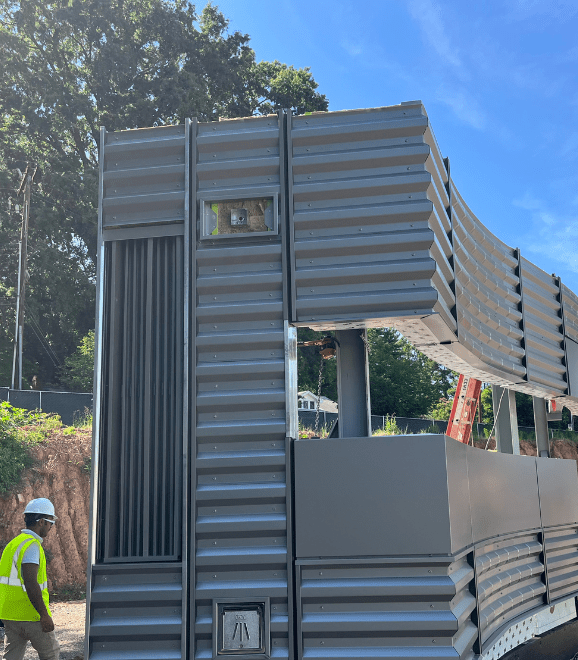

- Improper handling or lifting

- Uneven substrates or structural frames

- Inconsistent fastening techniques

How to Overcome It:

- Use laser levels and total stations for precise alignment and layout.

- Pre-mark guide lines on the substrate or structure before lifting panels into place.

- Employ installation jigs or mechanical guides to ensure consistent spacing and vertical/horizontal positioning.

- Coordinate with the panel manufacturer to ensure proper panel sequencing and lifting techniques are followed.

Ensuring accurate alignment not only improves visual consistency but also ensures a tighter building envelope, enhancing both weather protection and energy performance.

2. Thermal Bridging

The Challenge:

Thermal bridging occurs when materials that conduct heat—like metal fasteners or framing—create a path for heat loss through the wall system. This undermines insulation performance, increases heating and cooling costs, and can lead to condensation within the wall assembly.

Causes:

- Metal components passing through insulation layers

- Lack of thermal breaks between structural members and panels

- Incomplete or improperly installed insulation

How to Overcome It:

- Incorporate continuous insulation in the wall system, especially in panel joints and transitions.

- Use thermal break technologies, such as insulated fasteners or thermally isolated sub-framing systems.

- Design panels to include pre-installed insulation layers that wrap around structural elements without interruption.

- Conduct a thermal analysis during design to identify and mitigate bridging hot spots.

When thermal bridging is properly addressed during exterior wall panel installation, it enhances energy efficiency and helps meet stringent building code requirements.

3. Improper Sealing and Moisture Intrusion

The Challenge:

If air and moisture barriers are not properly integrated at panel joints and penetrations, water infiltration and air leakage can result—leading to mold, rot, and decreased energy efficiency.

Causes:

- Incomplete or poorly installed sealants

- Incompatible or untested materials

- Inconsistent compression of exterior wall panel gaskets

- Discontinuous Exterior Wall Panel Air & Vapor Barrier (AVB) layers

How to Overcome It:

- Use factory-applied or pre-tested AVB membranes on each panel for consistent performance.

- Ensure proper gasket compression at joints by following manufacturer specifications for tolerances and fastening torque.

- Seal all joints with compatible tapes, sealants, or pre-applied gaskets, and use redundant sealing methods in high-exposure zones.

- Inspect transitions between panels, windows, and doors to confirm AVB continuity.

An effective Exterior Wall Panel Air & Vapor Barrier (AVB) system, properly integrated with exterior wall panel gaskets, is critical for maintaining a high-performance, watertight building envelope.

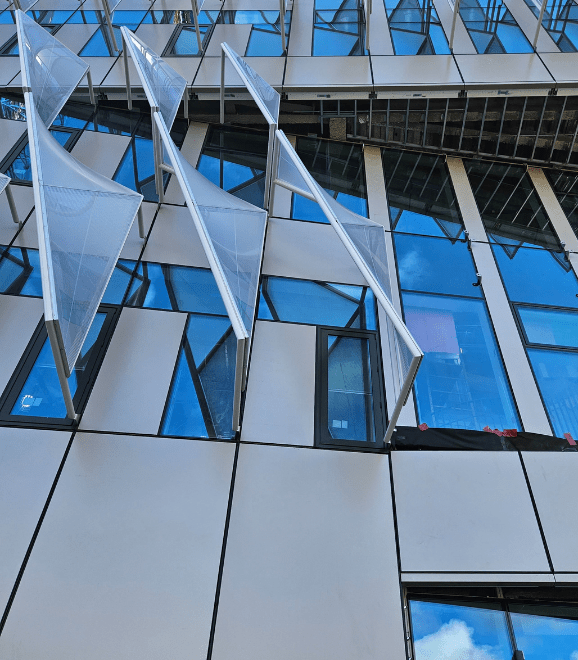

4. Gasket Compression and Joint Failures

The Challenge:

Exterior wall panel gaskets are essential for sealing out air and water at panel joints. But improper installation—either over-compressing or under-compressing gaskets—can lead to early failure, water leaks, and air infiltration.

Causes:

- Incorrect fastener torque

- Irregular panel spacing

- Damaged or misaligned gaskets

- Thermal expansion not accounted for in joint design

How to Overcome It:

- Follow manufacturer guidelines for gasket type, placement, and compression requirements.

- Use torque-controlled tools to achieve proper fastener tension and avoid crushing gaskets.

- Check for debris or misalignment that could prevent proper gasket seating.

- Account for thermal movement with joint design that allows controlled expansion and contraction.

By ensuring exterior wall panel gaskets are correctly installed and maintained, you protect the wall assembly against moisture intrusion and improve the overall integrity of the system.

5. Inconsistent Air & Vapor Barrier Continuity

The Challenge:

A continuous Exterior Wall Panel Air & Vapor Barrier (AVB) is essential to prevent conditioned air from escaping and moisture from entering. Even small gaps or overlaps in AVB layers can lead to significant performance losses.

Causes:

- Gaps between panels or membrane sheets

- Poor adhesion or incompatible sealants

- Mismatched transitions between dissimilar materials

- Improper sequencing of barrier installation

How to Overcome It:

- Design panels with pre-integrated AVB membranes to reduce reliance on field-applied barriers.

- Use AVB-compatible tapes, gaskets, and sealants at all panel edges and penetrations.

- Train installers thoroughly on sequencing, overlap tolerances, and product compatibility.

- Perform blower door tests or smoke tests post-installation to verify airtightness.

Proper AVB integration during exterior wall panel installation ensures better indoor air quality, energy savings, and building durability.

6. Weather-Related Installation Delays

The Challenge:

Rain, snow, and extreme temperatures can disrupt installation schedules and compromise the performance of adhesives and sealants used on-site.

Causes:

- Unprotected materials stored on-site

- Inability to install AVB or sealants during wet or cold conditions

- Delayed drying or curing of moisture-sensitive products

How to Overcome It:

- Use prefabricated panels with factory-applied AVB and gaskets to reduce reliance on field application in poor weather.

- Store panels and sealants in weather-protected areas with controlled temperatures.

- Schedule critical installation tasks during forecasted dry windows whenever possible.

- Use all-weather-compatible materials rated for installation in varying conditions.

Prefabrication dramatically reduces weather-related risks by completing the majority of wall assembly in a controlled environment before exterior wall panel installation even begins.

Conclusion: Success Lies in the Details

Installing wall panels isn’t just about speed—it’s about precision, protection, and performance. From aligning panels and preventing thermal bridging to sealing joints with exterior wall panel gaskets and ensuring AVB continuity, the devil is in the details.

By proactively addressing these common challenges in exterior wall panel installation, construction teams can avoid costly rework, prevent performance failures, and deliver buildings that are both visually striking and structurally sound.

With thorough planning, skilled labor, and quality materials—including a high-performing Exterior Wall Panel Air & Vapor Barrier (AVB)—you’ll create an envelope that stands up to the elements, enhances energy efficiency, and maintains its appearance for decades to come.