What Are Prefabricated Exterior Wall Panels?

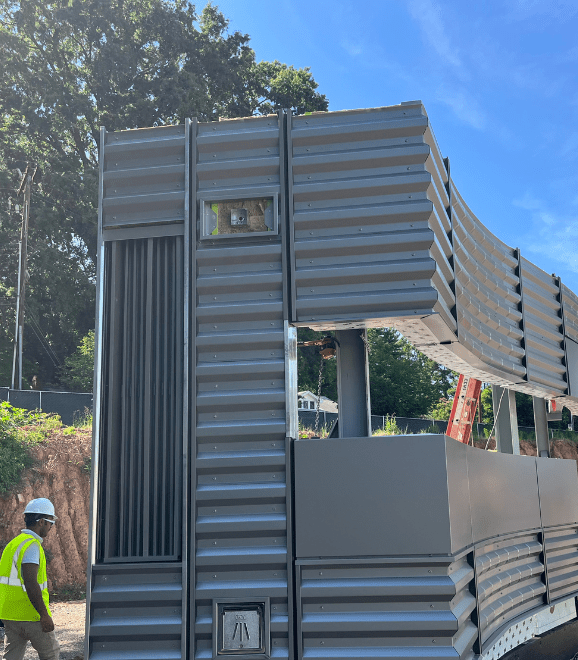

Prefabricated exterior wall panels are factory-built wall assemblies designed to be installed directly onto a building’s structural frame. These panels typically include insulation, sheathing, air/vapor barriers, cladding, and even windows—all integrated into one cohesive unit. Prefabricated exterior wall systems are engineered off-site, shipped to the job site, and rapidly installed using cranes or other lifting equipment.

In contrast, traditional construction involves assembling wall components—such as framing, sheathing, insulation, and cladding—piece by piece on-site, which can be labor-intensive, weather-dependent, and prone to quality inconsistencies.

Cost Considerations

1. Material and Labor Costs

Traditional Construction:

- Requires a wide variety of materials delivered in bulk

- High labor cost due to multiple trades working on framing, insulation, cladding, etc.

- Risk of material waste from field modifications and errors

- Weather delays can add to labor costs and scheduling inefficiencies

Prefabricated Exterior Wall Panels:

- Upfront costs may appear higher due to manufacturing and transportation

- Lower on-site labor costs due to faster installation

- Reduced waste through precise, factory-controlled production

- Fewer trades needed on-site, minimizing overlap and inefficiencies

Verdict: While prefabricated exterior wall panels may seem more expensive initially, they often offset those costs through labor savings and waste reduction. Over time, they typically prove to be more cost-effective, especially on mid- to large-scale projects.

Time Efficiency

2. Construction Schedule Impact

Traditional Construction:

- Sequential installation requires careful scheduling and coordination among multiple subcontractors

- Delays caused by weather, trade conflicts, or site logistics can extend timelines

- On-site adjustments and inspections can slow progress

Prefabricated Exterior Wall Systems:

- Fabrication happens concurrently with site preparation and structural framing

- Panels can be installed quickly once the building frame is ready—often several stories per day

- Reduced weather impact because most work is completed off-site

- Faster enclosure allows for earlier interior work and project completion

Verdict: Prefabricated exterior wall systems offer significant time savings, often shortening project schedules by weeks or even months. For developers, this can mean faster time-to-market and earlier revenue generation.

Quality and Performance

3. Consistency and Quality Control

Traditional Construction:

- Quality depends on field conditions and craftsmanship variability

- High potential for discrepancies between design intent and execution

- On-site weather exposure during construction can compromise material performance

Prefabricated Exterior Wall Panels:

- Built in climate-controlled factories using precision tools and automation

- Subject to strict quality control, testing, and standardization

- Panels arrive complete and protected, reducing risk of weather-related damage

Verdict: With factory-level consistency, prefabricated exterior wall systems significantly reduce construction defects and deliver higher quality performance across the board.

Building Envelope Performance

4. Thermal, Air, and Moisture Management

Traditional Construction:

- Disjointed installation of insulation, air barriers, and cladding can lead to thermal bridging, air leaks, or water intrusion

- Performance heavily relies on on-site detailing and proper sequencing

Prefabricated Exterior Wall Systems:

- Integrated insulation and air/vapor barriers reduce thermal bridging

- Consistent application of weatherproofing and moisture control layers

- Panels can be tested for performance before leaving the factory

Verdict: Prefabricated exterior wall panels provide superior building envelope performance, supporting higher energy efficiency and better compliance with energy codes like IECC, ASHRAE 90.1, and LEED certification standards.

Lifecycle Cost and Long-Term Value

5. Maintenance and Durability

Traditional Construction:

- Higher likelihood of performance issues due to inconsistent craftsmanship

- May require more frequent repairs or envelope maintenance over the years

- Moisture infiltration risks can compromise structural components

Prefabricated Exterior Wall Panels:

- Engineered systems with integrated protection against moisture and air infiltration

- Factory-tested connections and finishes lead to greater longevity

- Lower operating costs due to better thermal and moisture resistance

Verdict: In the long run, prefabricated exterior wall systems outperform traditional assemblies in terms of durability, reducing operating and maintenance costs over the building’s lifespan.

Design Flexibility and Aesthetic Options

6. Architectural Impact

Traditional Construction:

- Offers flexibility for last-minute design changes

- Field adjustments are easier, though they may cause delays and inconsistencies

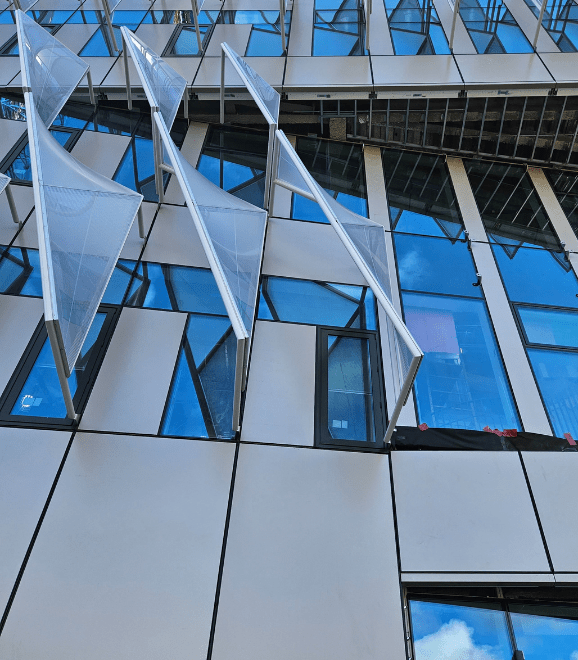

Prefabricated Exterior Wall Systems:

- Modern panel systems accommodate a wide range of architectural styles, materials, and finishes (e.g., metal, stone, HPL, glass)

- Panels can be customized for window openings, decorative elements, and integrated shading devices

- Requires early design decisions and coordination with the manufacturer

Verdict: With proper planning, prefabricated exterior wall panels can achieve complex, high-end aesthetics while still offering performance and speed benefits.

Environmental and Sustainability Benefits

7. Waste and Resource Management

Traditional Construction:

- Generates significant on-site waste due to cut-offs, damaged materials, and packaging

- Less control over sourcing and sustainability of materials

Prefabricated Exterior Wall Panels:

- Minimizes material waste through precise cutting and reuse in factories

- Panels often use environmentally certified materials and support LEED goals

- Lower site disturbance and emissions due to shorter construction timelines

Verdict: For projects seeking sustainable certification or eco-conscious design, prefabricated exterior wall systems provide a cleaner, more resource-efficient solution.

Final Thoughts: Which System Offers the Better Value?

When evaluating building methods, it’s essential to look beyond just upfront costs. The benefits of prefabricated exterior wall panels extend far beyond the factory—offering faster construction timelines, enhanced performance, long-term savings, and superior quality.

While traditional construction may offer flexibility and familiarity, it is increasingly being outpaced by the cost-efficiency, consistency, and scalability of prefabricated exterior wall systems—especially in commercial, institutional, and high-density residential projects.