What Are Exterior Wall Panel Girts?

Exterior wall panel girts are horizontal or vertical framing members installed between a building’s main structural frame and the exterior wall panels. Typically made from steel or aluminum, these members act as a secondary structural system that distributes loads from the wall panels back to the primary frame of the building.

Girts can be cold-formed steel channels, z-shaped sections, or custom-engineered profiles designed to accommodate specific panel systems. They play a vital role in the support of prefabricated exterior wall panels, especially in systems that demand rapid installation, design flexibility, and high performance.

The Core Function of Girts in Wall Systems

While often hidden behind cladding and insulation, exterior wall panel girts are key structural elements that serve several functions:

1. Support and Anchorage

Girts provide a solid anchoring point for prefabricated exterior wall panels, allowing them to be securely fastened without relying solely on the primary structure. This simplifies installation and improves alignment.

2. Load Distribution

Girts transfer the weight of the wall system—along with environmental loads such as wind or seismic forces—to the building’s steel or concrete frame. This reduces stress concentrations and enhances structural stability.

3. Spacing and Layout Control

By dictating the spacing of wall panel attachments, girts help standardize panel dimensions and configurations, which is especially helpful in modular or panelized systems.

4. Thermal and Moisture Integration

Modern girts often include features for supporting continuous insulation and rain screen systems, improving the building envelope’s thermal performance and weather resistance.

Girts and Design Flexibility: A Game-Changer for Architects

One of the primary benefits of using exterior wall panel girts is the design flexibility they introduce to the wall system. Here’s how they enable customization while maintaining structural performance:

1. Freedom in Cladding Selection

Because girts decouple the cladding from the structural frame, architects are free to specify a wide range of exterior materials—such as metal, fiber cement, high-pressure laminate (HPL), terra cotta, or wood panels. These can be easily mounted to the girts, allowing for a diverse palette of textures, colors, and finishes without compromising on system integrity.

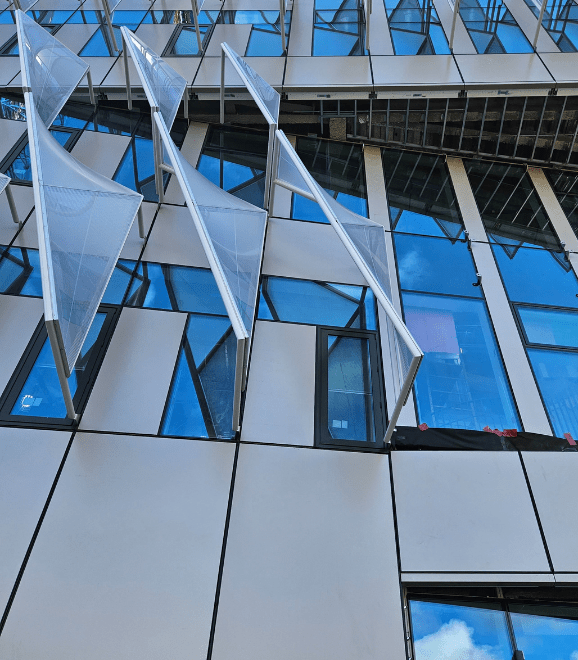

2. Compatibility with Complex Facades

Curved walls, overhangs, vertical fins, or deep recesses can all be achieved more easily when prefabricated exterior wall panels are supported by flexible girt systems. Girts can be spaced or shaped to accommodate custom geometries, helping designers bring complex façade ideas to life.

3. Panel Modularity

Girts simplify the integration of modular panels in different shapes and sizes, which is crucial in prefabrication. Because the wall panels can be pre-sized to align with the girt layout, installation becomes faster and more predictable—without sacrificing architectural intent.

Girts and Insulation: Enabling High-Performance Envelopes

In addition to enabling architectural creativity, exterior wall panel girts play a vital role in improving thermal performance—one of the most pressing priorities in modern construction.

1. Continuous Insulation Compatibility

Traditional wall systems often suffer from thermal bridging due to metal studs or anchors interrupting insulation layers. Girt systems designed with stand-offs or thermally broken brackets allow for continuous insulation to run uninterrupted between the girts and cladding layers.

This is especially advantageous in prefabricated exterior wall panels, where insulation can be installed in the factory along with sheathing and vapor barriers, reducing errors and labor costs on-site.

2. Moisture and Drainage Integration

Rain screen systems rely on ventilated cavities between insulation and cladding to prevent water intrusion and promote drying. Girts help create this cavity by spacing the cladding away from the insulation layer, enhancing moisture performance and extending the life of the wall system.

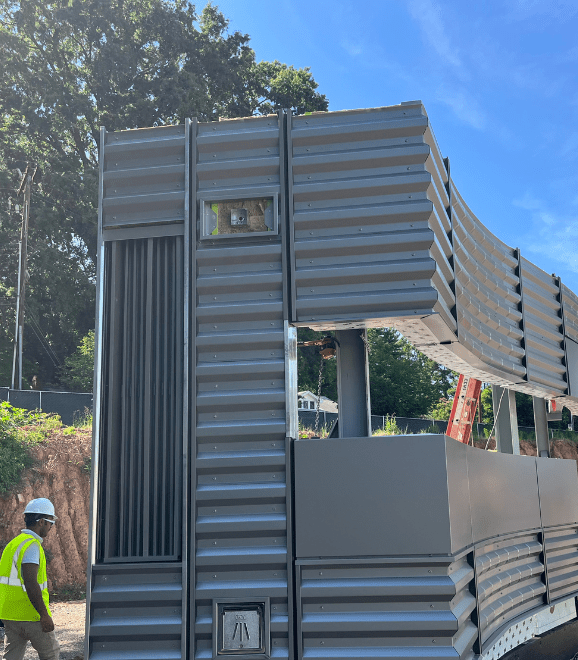

Girts in Prefabricated Exterior Wall Panels: Factory Precision, Field Efficiency

One of the biggest shifts in the construction industry is the move toward off-site manufacturing. Prefabricated exterior wall panels, built in controlled environments, allow for the integration of insulation, sheathing, vapor barriers, and cladding in one unitized system. Girts play a crucial role in this prefabricated approach.

Benefits in Prefabricated Panels:

- Pre-attached girts allow for quicker onsite alignment and fastening

- Improved quality control in factory-fabricated framing systems

- Reduced labor and faster enclosure of the building envelope

- Seamless integration of thermal, acoustic, and moisture barriers

By standardizing girt placement in prefabricated exterior wall panels, manufacturers can deliver repeatable, code-compliant wall systems that are both structurally efficient and architecturally versatile.

Common Girt Configurations and Materials

Horizontal Z-Girts

Z-shaped girts are commonly used for their simplicity and effectiveness. They’re mounted horizontally and are ideal for systems that require vertical cladding orientation.

Vertical Hat Channels

Hat-shaped girts are mounted vertically and work well with horizontally oriented cladding panels. These are often used in tandem with horizontal Z-girts in complex façade systems.

Thermally Broken Girts

Engineered girts with thermal breaks minimize conductive heat loss, improving the overall U-value of the wall assembly. These are increasingly used in high-performance and energy-efficient buildings.

Girt Materials

- Steel: Strong and widely available, used in both structural and architectural applications

- Aluminum: Lightweight and corrosion-resistant, ideal for coastal or corrosive environments

- Composite Materials: Used in specialty applications that require enhanced durability or insulation compatibility

Conclusion: Small Components, Big Impact

Although they are often hidden behind layers of insulation and cladding, exterior wall panel girts are foundational to the success of any wall system. From structural support and load distribution to enabling architectural expression and improving thermal performance, girts are a quiet hero in modern construction.

In the context of prefabricated exterior wall panels, girts unlock new possibilities in design, efficiency, and sustainability. By serving as the interface between structure and façade, they empower architects and engineers to build smarter, faster, and more creatively than ever before.

If your project demands both structural rigor and aesthetic flexibility, it’s time to take a closer look at the girt system behind your walls. When specified and designed correctly, exterior wall panel girts become the framework that turns architectural vision into built reality.