What Is an Air & Vapor Barrier (AVB)?

An Exterior Wall Panel Air & Vapor Barrier (AVB) is a specialized membrane or layer integrated into the wall assembly that performs two key functions:

- Air Barrier – Prevents the uncontrolled flow of air through the wall, improving energy efficiency and indoor comfort.

- Vapor Barrier – Controls the movement of moisture vapor to prevent condensation within the wall assembly.

When properly installed, an AVB prevents warm, moist air from entering and condensing inside the wall system in cold climates—or in hot, humid environments, stops moisture-laden exterior air from entering air-conditioned interiors.

The Importance of AVBs in Building Envelopes

The consequences of failing to properly manage air and vapor movement can be severe:

- Mold growth from trapped moisture

- Structural degradation from water damage

- Poor indoor air quality due to mold spores or pollutants

- Increased energy bills from uncontrolled air leakage

- Failed insulation performance due to moisture saturation

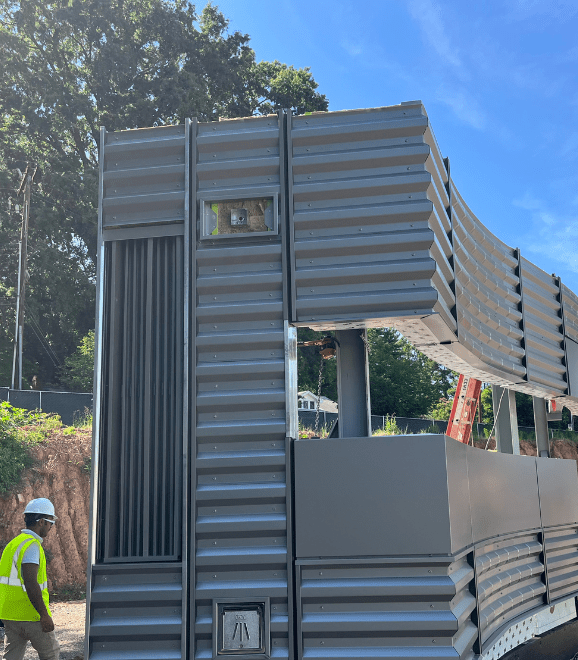

Incorporating a high-performance Exterior Wall Panel Air & Vapor Barrier (AVB) directly into prefabricated exterior wall systems addresses these challenges head-on by creating a continuous, high-integrity envelope before the panels ever reach the job site.

Benefits of Integrating AVBs in Prefabricated Wall Systems

The controlled factory environment of prefabricated exterior wall systems makes them ideal for precise, high-quality AVB integration. Here are some of the top benefits:

1. Precision Application

In a factory setting, AVBs can be applied with uniform thickness, proper adhesion, and complete continuity—something that’s often difficult to achieve consistently in field conditions.

2. Labor and Time Savings

Since the Exterior Wall Panel Air & Vapor Barrier (AVB) is pre-installed, there’s no need for separate trades or extended installation time on-site, which speeds up the building enclosure process.

3. Reduced Weather Delays

Factory application eliminates weather-related setbacks that often hinder on-site AVB installation. The panels arrive ready to be installed and sealed regardless of outdoor conditions.

4. Improved Quality Assurance

Prefabrication allows for thorough inspection, testing, and documentation of AVB performance before panels are ever shipped—reducing the risk of leaks and call-backs later.

How AVBs Work in Prefabricated Exterior Wall Systems

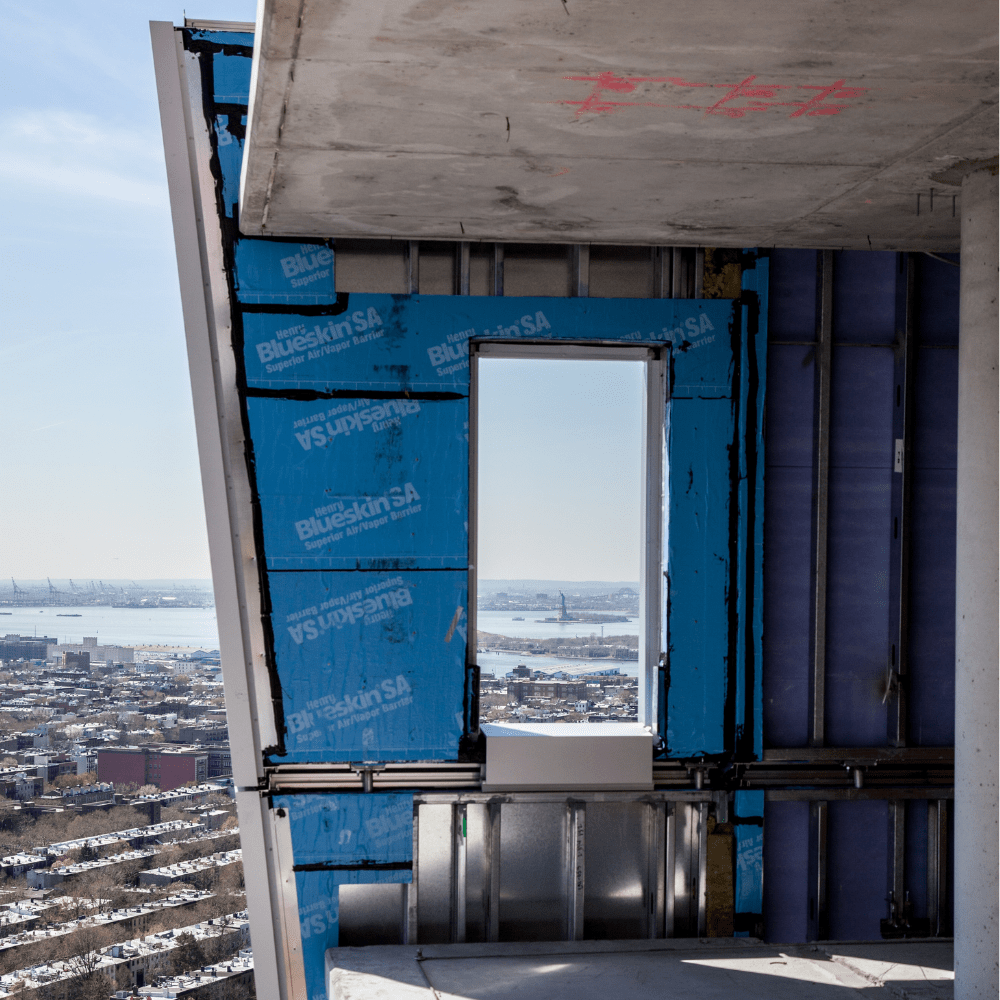

AVBs in prefabricated exterior wall systems are typically integrated as continuous sheets or coatings directly onto the sheathing layer of the panel. These systems may include:

- Fluid-applied membranes (spray- or roller-applied for seamless coverage)

- Self-adhered sheets (rolled onto the panel surface with pre-applied adhesive)

- Mechanically fastened membranes (held in place by fasteners, often used in combination with other barriers)

They are then paired with compatible sealants, tapes, or exterior wall panel gaskets at panel joints to maintain a continuous barrier once installed on-site. Integration with windows, doors, and penetrations is also detailed in the factory to ensure complete protection.

AVBs and Energy Efficiency

Air leakage is one of the most significant contributors to energy loss in buildings. According to the U.S. Department of Energy, air infiltration can account for up to 40% of a building’s heating and cooling energy use. A properly integrated Exterior Wall Panel Air & Vapor Barrier (AVB) drastically reduces this energy loss by sealing off uncontrolled pathways for air exchange.

Benefits include:

- Lower heating and cooling costs

- Improved occupant comfort through temperature consistency

- Reduced HVAC load and system wear

- Higher energy code compliance and green building ratings

When AVBs are part of prefabricated exterior wall systems, they contribute significantly to achieving net-zero energy goals and LEED certification targets.

AVBs and Indoor Air Quality

While energy efficiency is often the driving force behind AVB integration, indoor air quality (IAQ) is another critical benefit. By controlling air leakage, AVBs help prevent the intrusion of:

- Pollutants and allergens from outside air

- Mold-causing moisture that may develop within the wall cavity

- Dust and particulates entering through joints or cracks

Especially in healthcare facilities, schools, and high-performance commercial buildings, a well-sealed envelope made with Exterior Wall Panel Air & Vapor Barriers (AVB) contributes to healthier environments and better occupant well-being.

Common Challenges and How to Address Them

Even with prefabrication, some challenges exist in designing and installing effective AVBs. However, these can be mitigated through early planning and collaboration.

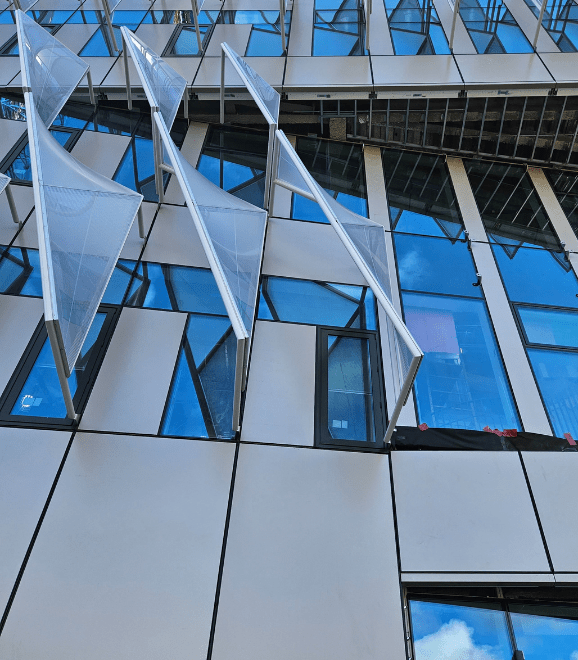

Challenge 1: Ensuring Continuity at Joints

Solution: Use AVB-compatible sealants, tapes, or gaskets to bridge the gaps between panels on-site. Panel connection details should be developed early in the design phase to ensure continuity.

Challenge 2: Material Compatibility

Solution: Choose AVB systems that are compatible with other layers in the wall assembly—such as insulation, cladding attachment systems, and flashing materials—to avoid adhesion or performance issues.

Challenge 3: Moisture Trapping in Wall Cavity

Solution: Design AVB placement and wall ventilation strategies according to climate zone. In mixed or humid climates, vapor-permeable membranes may be more appropriate than impermeable vapor barriers.

Design Considerations for Integrating AVBs

- Climate Sensitivity: Choose between permeable or impermeable AVBs based on whether vapor drive is expected from the interior or exterior.

- Location in Assembly: Typically, AVBs are placed on the exterior sheathing layer but may also be located elsewhere in the assembly depending on performance requirements.

- Sealant Strategy: All edges, joints, and penetrations must be sealed with compatible materials to prevent AVB discontinuity.

- Testing and Validation: Conduct blower door testing and third-party inspections to verify AVB performance on-site.

Conclusion

In the evolving world of sustainable, high-performance building design, the integration of Exterior Wall Panel Air & Vapor Barriers (AVB) is no longer optional—it’s essential. These barriers are vital for controlling moisture, preventing air infiltration, and enhancing both energy performance and indoor air quality.

When incorporated into prefabricated exterior wall systems, AVBs offer unmatched consistency, efficiency, and durability. With the right design, materials, and installation practices, AVBs can protect your building for decades—keeping interiors dry, healthy, and comfortable.

As buildings grow more complex and performance expectations rise, AVBs are the silent guardian within your walls—making all the difference between a building that just stands, and one that truly performs.