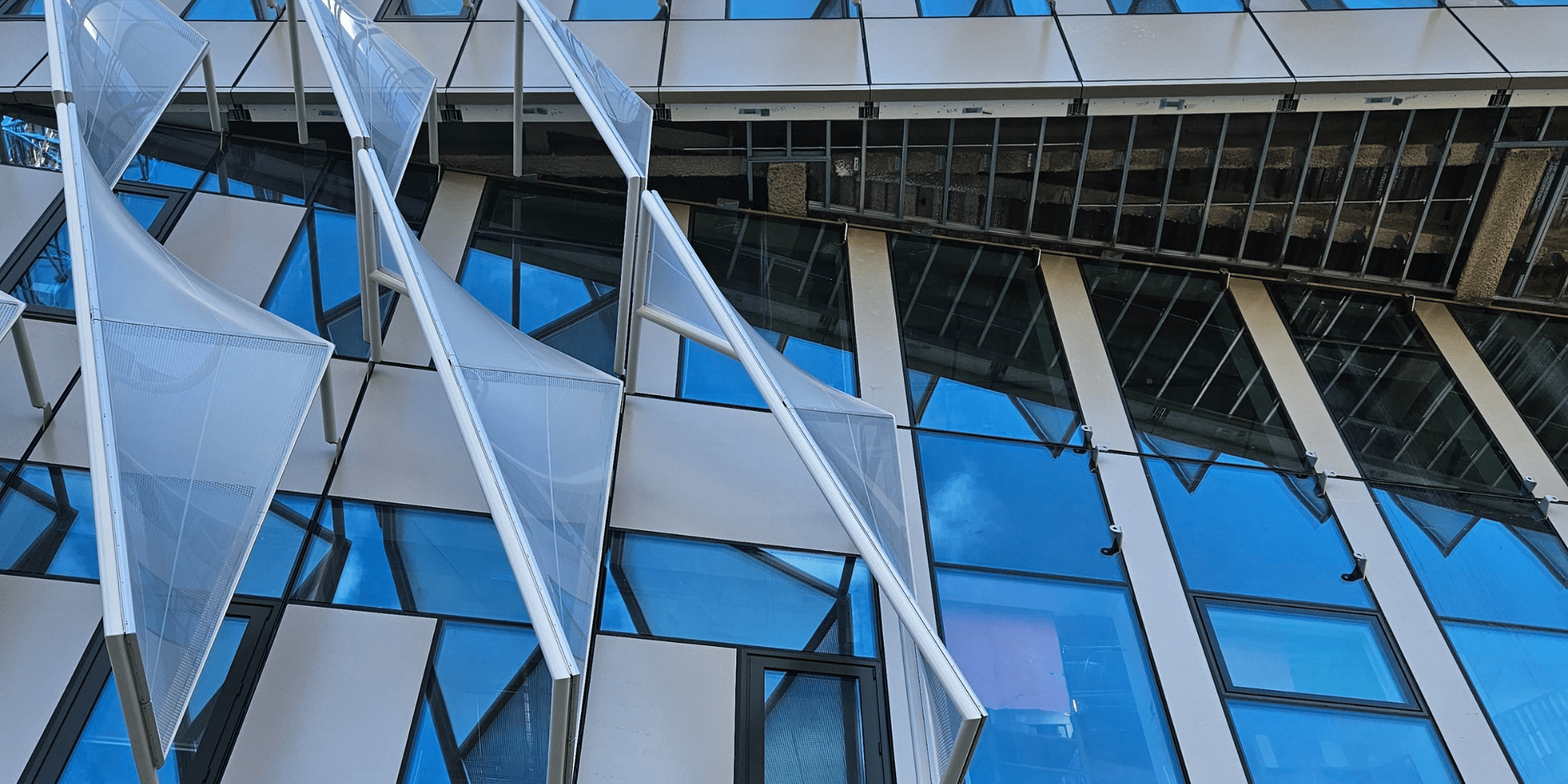

Extrusions & Gaskets

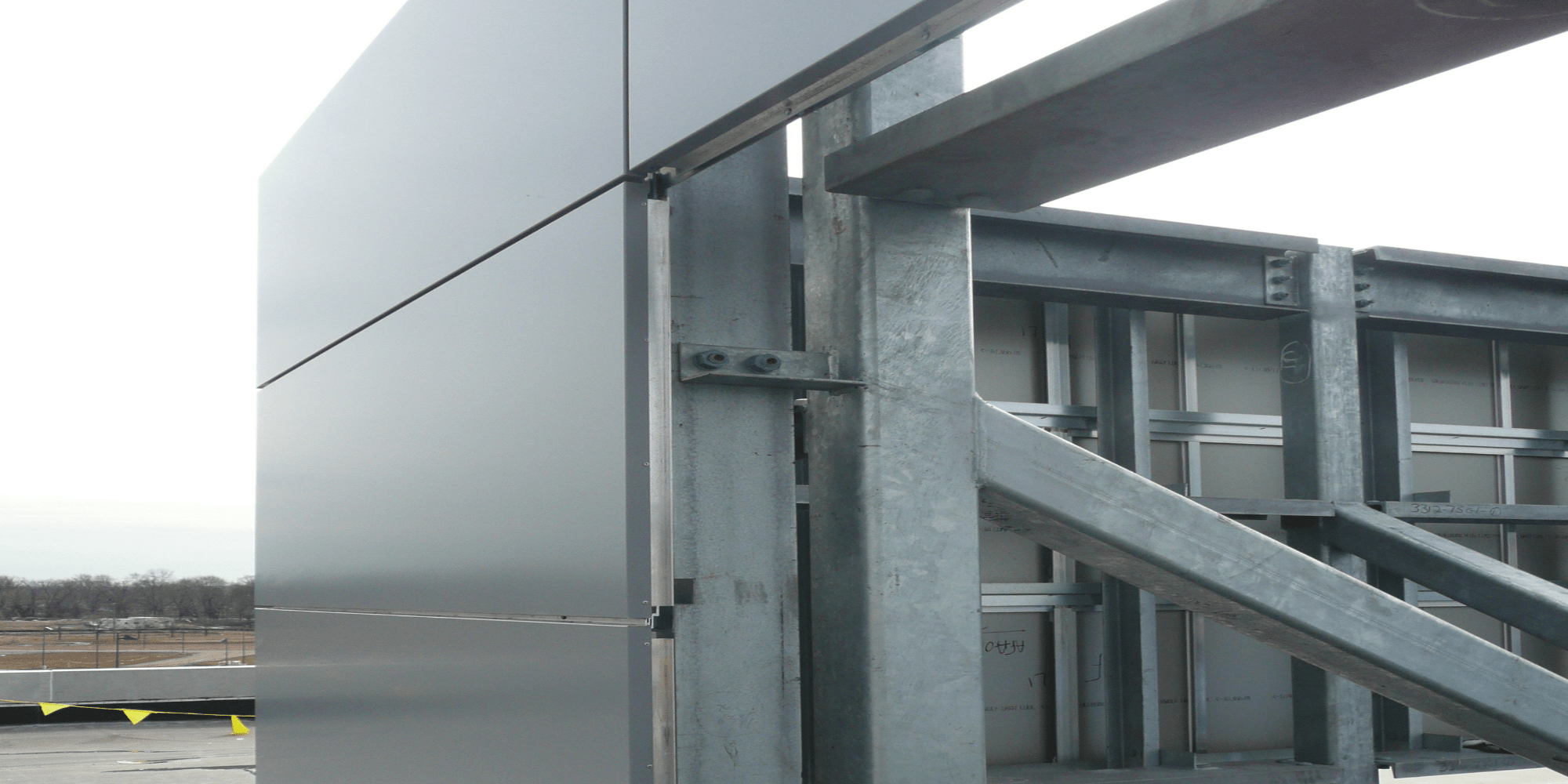

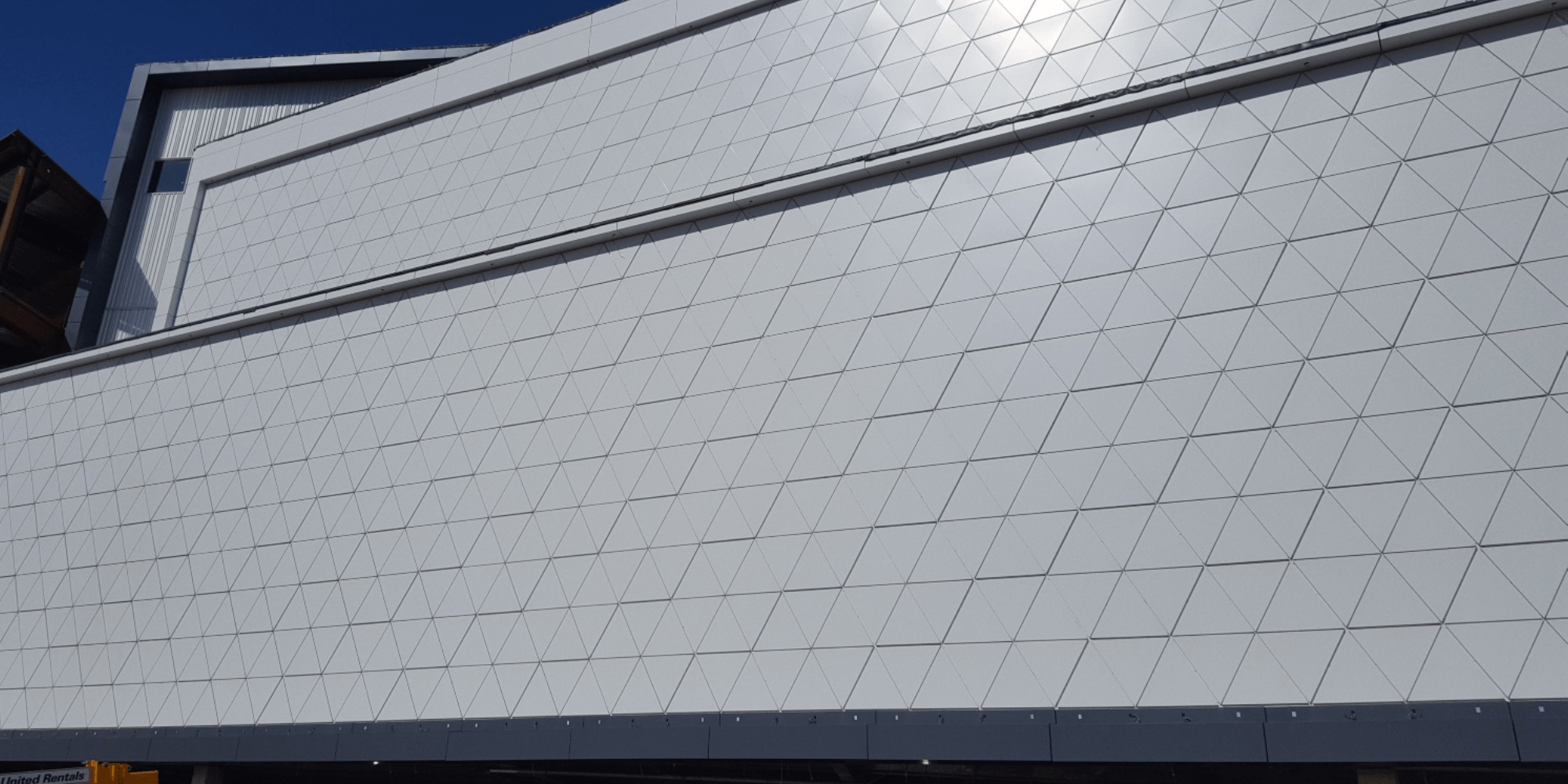

To seal our wall panel assemblies, we utilize a dry gasket system which deliver superior weather resistance, improved safety, and faster installation timelines to wet sealants. EEWS connects it’s panels together by using metal extrusions from manufacturers such as BRT, Hyrdo, Almag, Astro Shapes, and grp. These components allow for our panels to come together with precision and maintain a continuous envelope after installation.

Need Fabrication Design Services?

Need something custom for your fabrication project? Contact us to discuss your project details.

Dry Gasket System

We utilize a dry gasket system in our wall panel assemblies to deliver superior weather resistance, improved safety, and faster installation timelines. Unlike traditional wet sealant systems, our dry gaskets are factory-installed, eliminating many of the risks and maintenance challenges associated with field-applied sealants.

Advantages

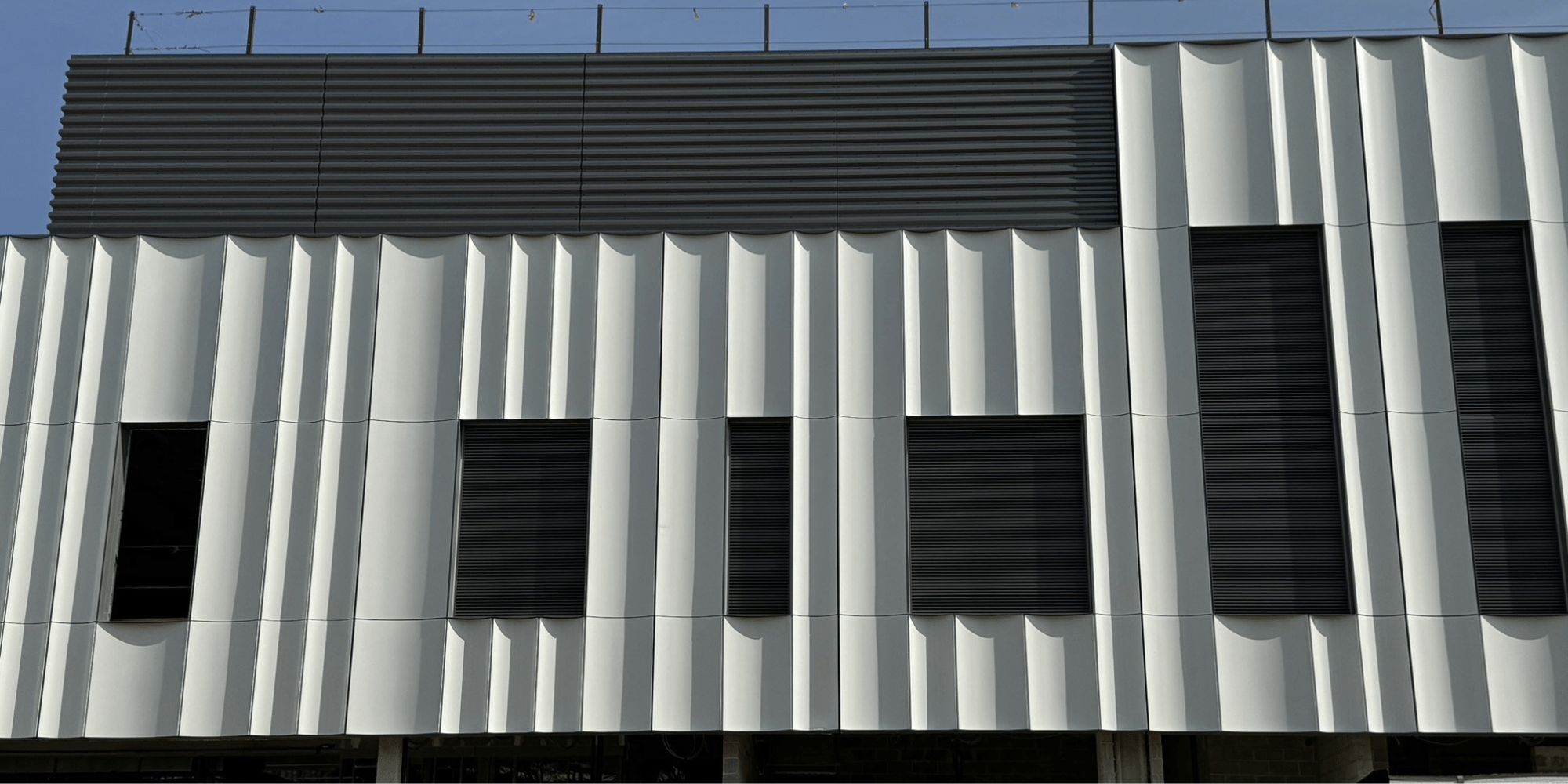

Improved Quality & Reliability

By removing the dependency on field labor for critical weatherproofing tasks, the dry gasket system ensures more consistent and reliable performance. Every gasket is installed in a controlled environment, with strict quality assurance checks in place, delivering predictable results that meet or exceed industry standards for air and water infiltration resistance.

Long-Term Value

Dry gasket systems are designed for durability, resisting UV exposure, temperature fluctuations, and weathering over time. This resilience translates to a lower total cost of ownership, fewer future repairs, and a longer-lasting high-performance building envelope, providing added value for owners and developers.

FAQ

What is a gasket and why is it important?

What is a gasket and why is it important?

A gasket is a mechanical seal that fills the space between two or more mating surfaces, preventing leaks from or into the joined objects while under compression. To ensure leak-proof operations, they are crucial in various applications, including automotive engines, plumbing systems, and industrial machinery.

What types of gaskets are available on EEWS?

What types of gaskets are available on EEWS?

EEWS.com offers a diverse range of gaskets, including:

Automotive Gaskets: For engines, exhaust systems, and cylinder heads.

Industrial Gaskets: Such as flange gaskets and insulating gasket kits.

Appliance Gaskets: Like door seals for refrigerators and ovens.

How do I choose the right gasket for my needs?

How do I choose the right gasket for my needs?

Selecting the appropriate gasket depends on factors like:

Application: Automotive, industrial, or household.

Material Compatibility: Ensure the gasket material is compatible with the substances it will contact.

Temperature and Pressure Requirements: Choose gaskets that can withstand the operating conditions of your system.

Are the gaskets on EEWS.com OEM or aftermarket?

Are the gaskets on EEWS.com OEM or aftermarket?

EEWS.com provides both OEM (Original Equipment Manufacturer) and high-quality aftermarket gaskets, catering to various customer preferences and requirements.

What materials are commonly used in gaskets?

What materials are commonly used in gaskets?

Common gasket materials include:

Rubber: Flexible and suitable for low-pressure applications.

Metal: Ideal for high-temperature and high-pressure environments.

Cork: Used in applications requiring compressibility and flexibility.

Composite Materials: Combine properties of different materials for specialized applications.

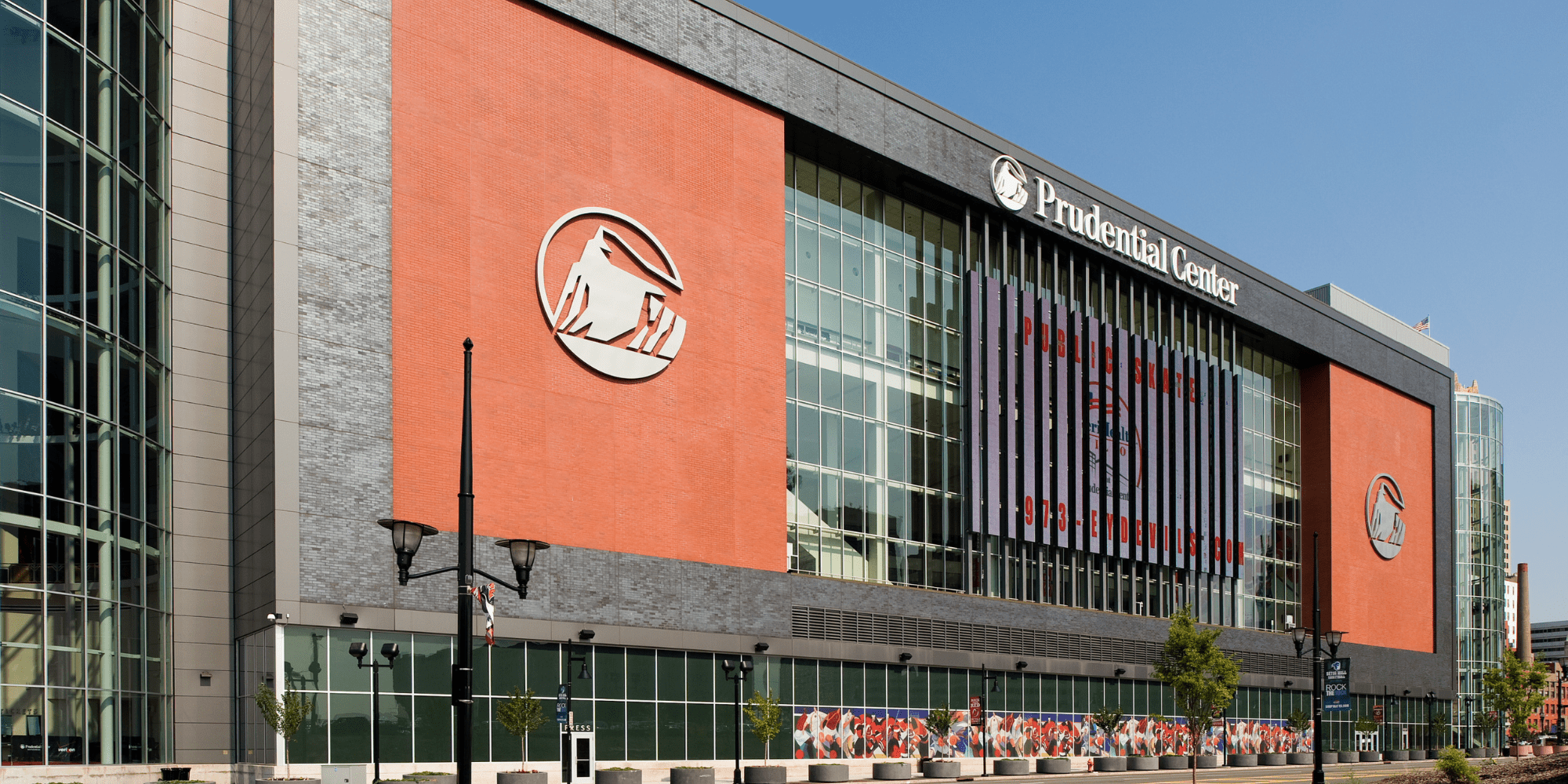

Maximizing The benefits Of Prefabrication

Design Assist

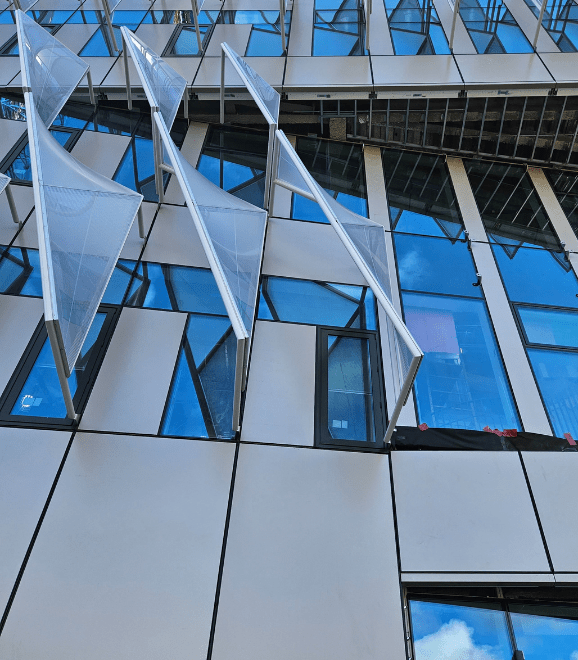

Our collaborative process unites one experienced team from design through installation. In-house Revit-certified designers ensure every detail is carefully planned and executed. Early alignment on goals and continuous design and budget feedback keep projects on track. This streamlined approach eliminates inefficiencies and delivers reliable, high-quality results.

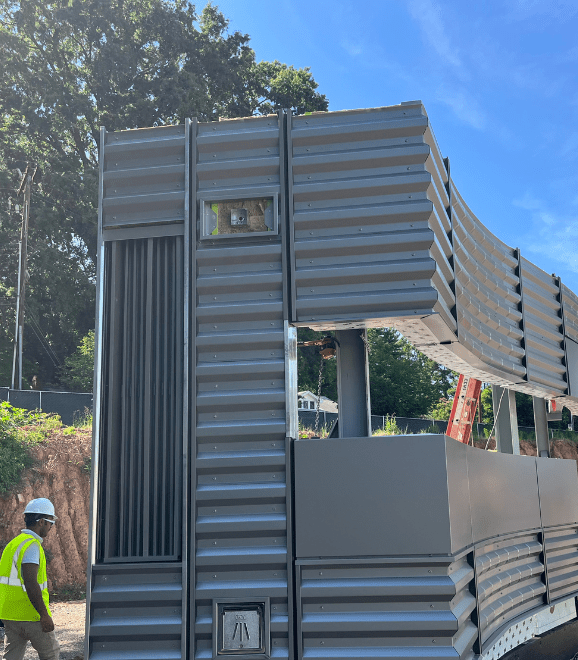

Safer Job Site

Our panelized enclosure system reduces on-site labor and shortens the project timeline, cutting labor costs. Pre-engineered and assembled off-site, it eliminates material storage, site congestion, and waste. Fewer trades are needed on-site, creating a cleaner, safer work environment. This streamlined process also lowers the risk of accidents and boosts site efficiency.

Quality Assurance

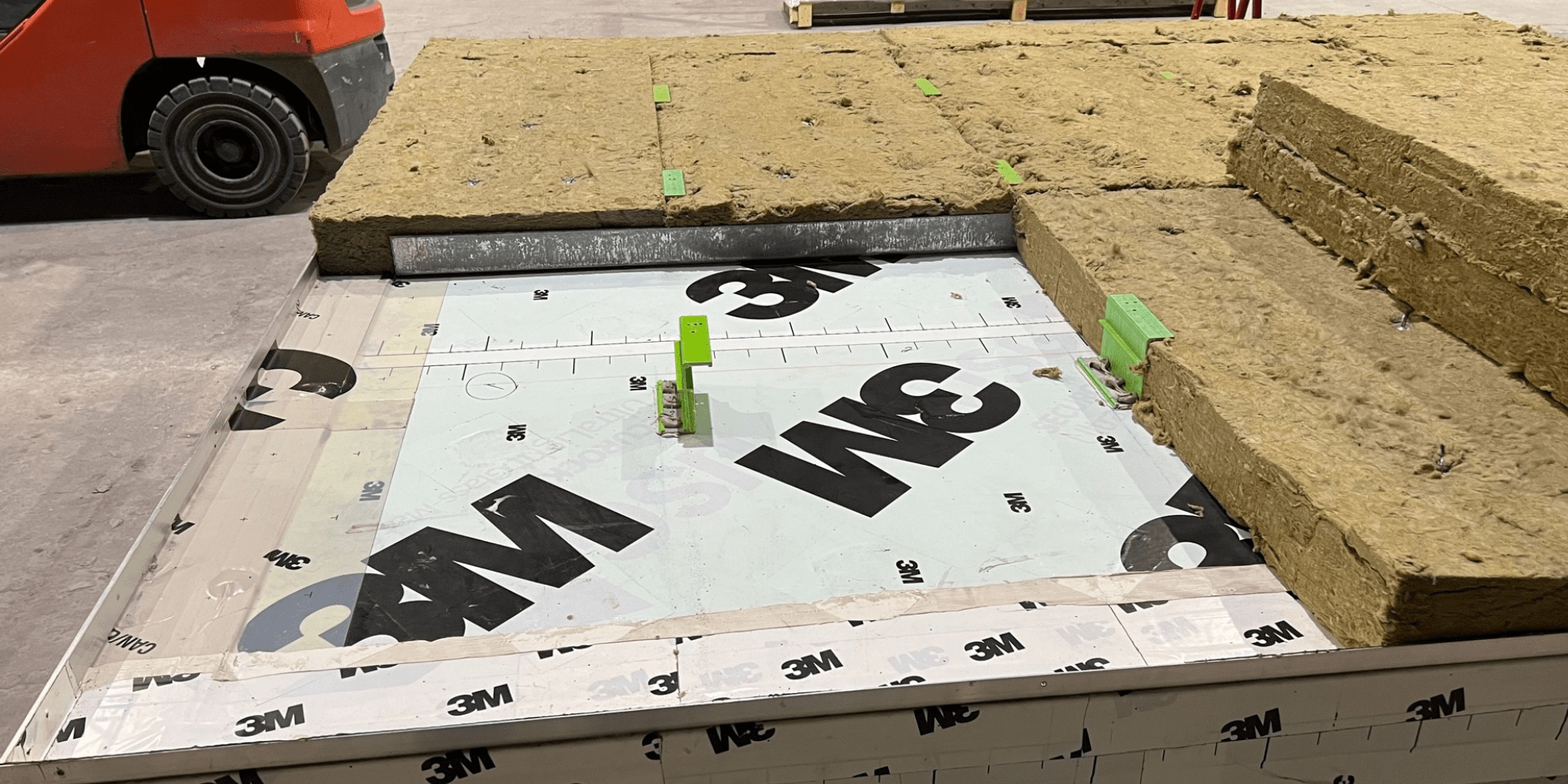

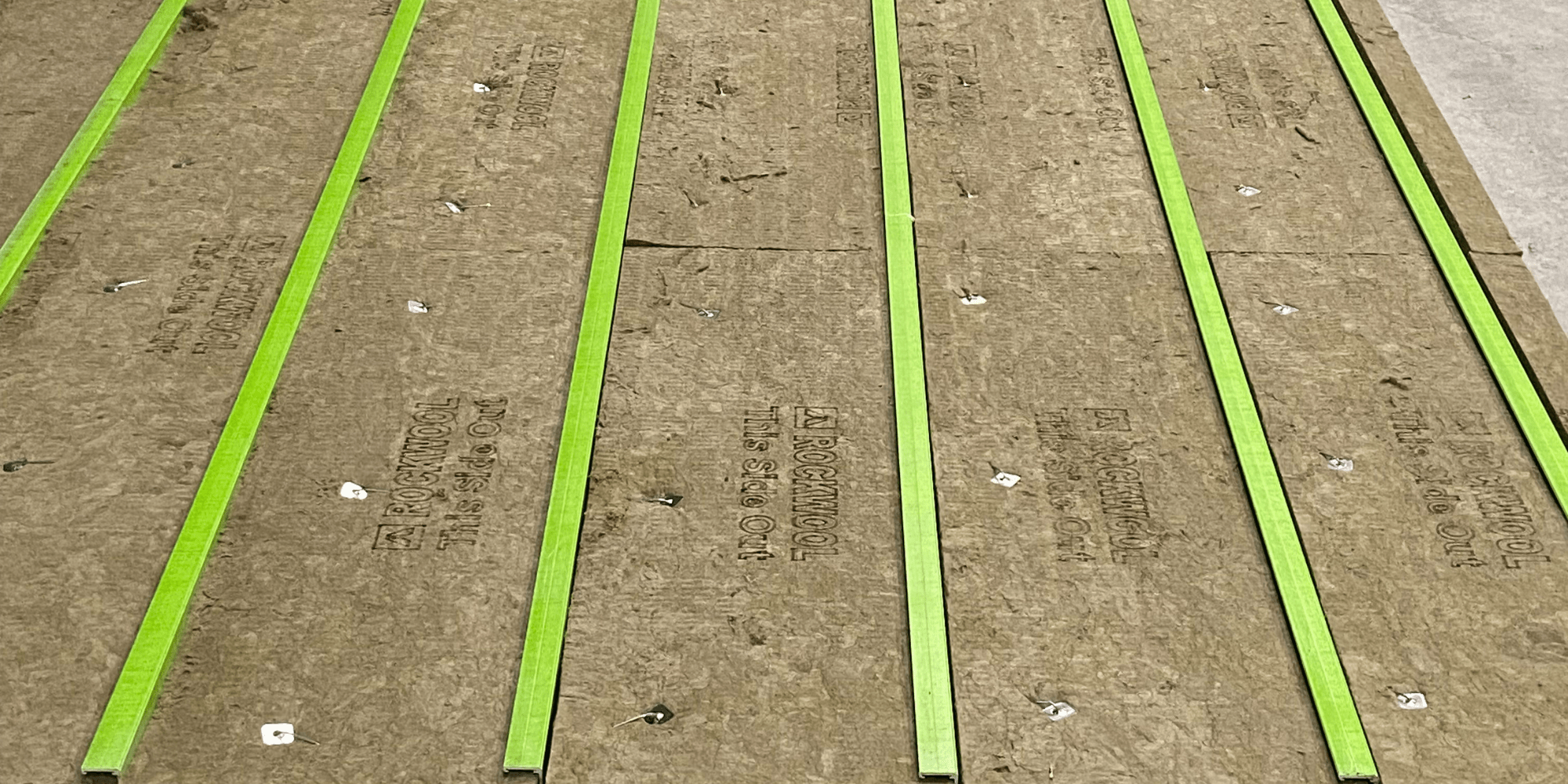

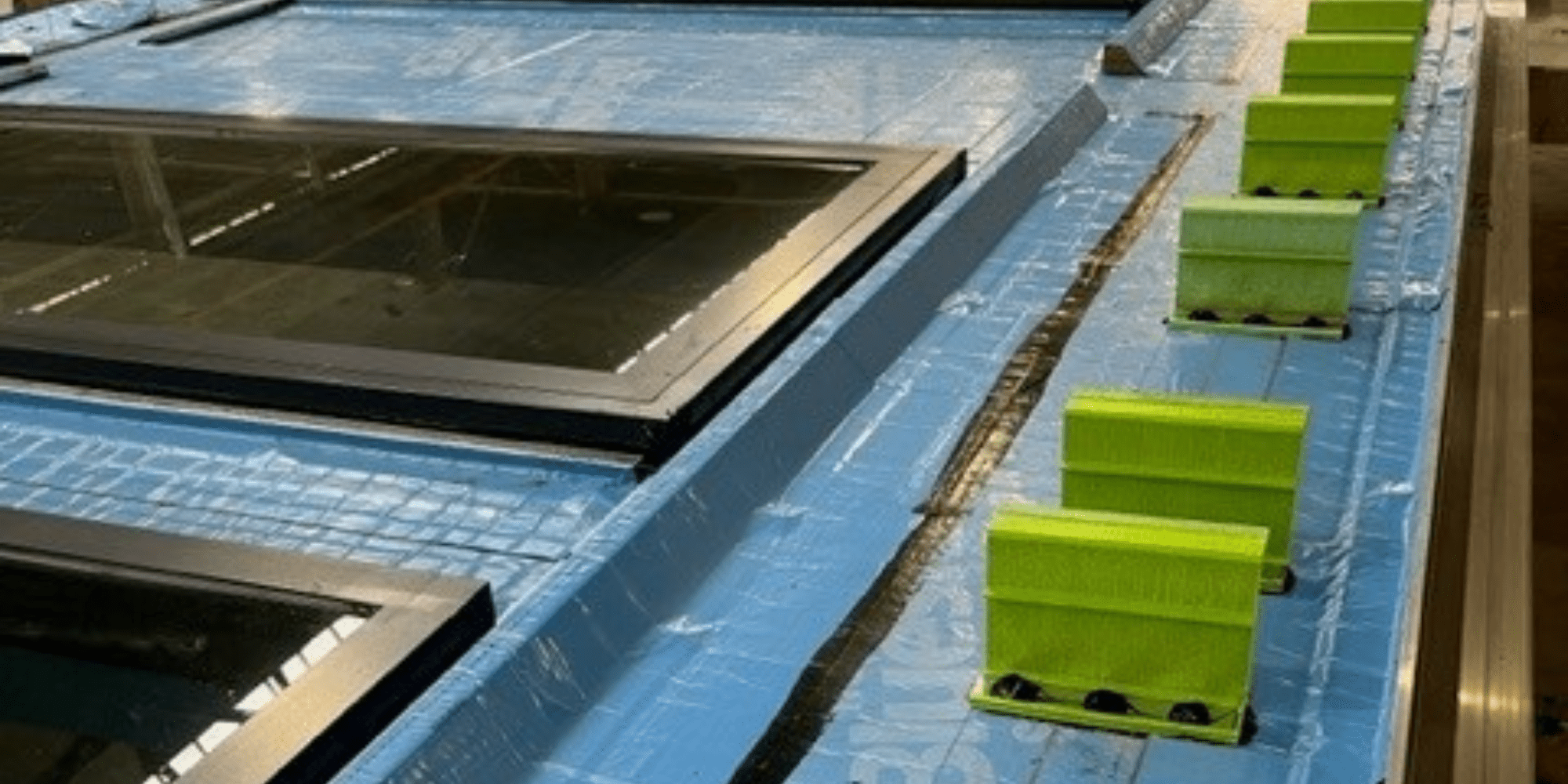

Our panelized systems provide superior thermal, moisture, and air performance through a continuous, high-quality enclosure. Assembled in a controlled facility, components like AVB, windows, and louvers are installed with precision. A single expert team handles multiple trades, reducing gaps and delays. This process also simplifies inspections and ensures consistent quality.

Building Enclosure Speed

Prefabricated panel systems greatly speed up the building enclosure process. Off-site fabrication in a controlled environment allows for faster dry-in and earlier interior work. This reduces weather delays and shortens the overall schedule. It’s an ideal solution for projects with tight timelines or phased occupancy.

Coordinated Engineered Interfaces Solutions

Our system features fully coordinated, engineered interfaces for seamless integration of all enclosure components. Key details are resolved during design and fabrication, avoiding on-site conflicts. This approach minimizes field adjustments and ensures consistent quality. The result is a unified, high-performing building envelope from day one.

Logistics

Prefabricated enclosure systems streamline logistics by reducing the volume of material delivered to and stored on-site. With just-in-time delivery and panels arriving in sequence, site congestion, waste, and handling are minimized. This controlled flow of materials supports cleaner, safer job sites and simplifies coordination among trades. The result is a more efficient, organized construction process that aligns with modern lean building practices.

Thermal Performance

When design allows, increasing opaque wall areas with prefabricated systems can greatly improve thermal performance. Fewer unitized joints enhance energy efficiency and air-tightness. These systems also offer broad cladding flexibility, giving architects more design freedom. In this case, the prefabricated enclosure is over four times more energy efficient than a traditional glass curtain wall.

Need Fabrication Services?

Need something custom for your fabrication project? Contact us to discuss your project details.

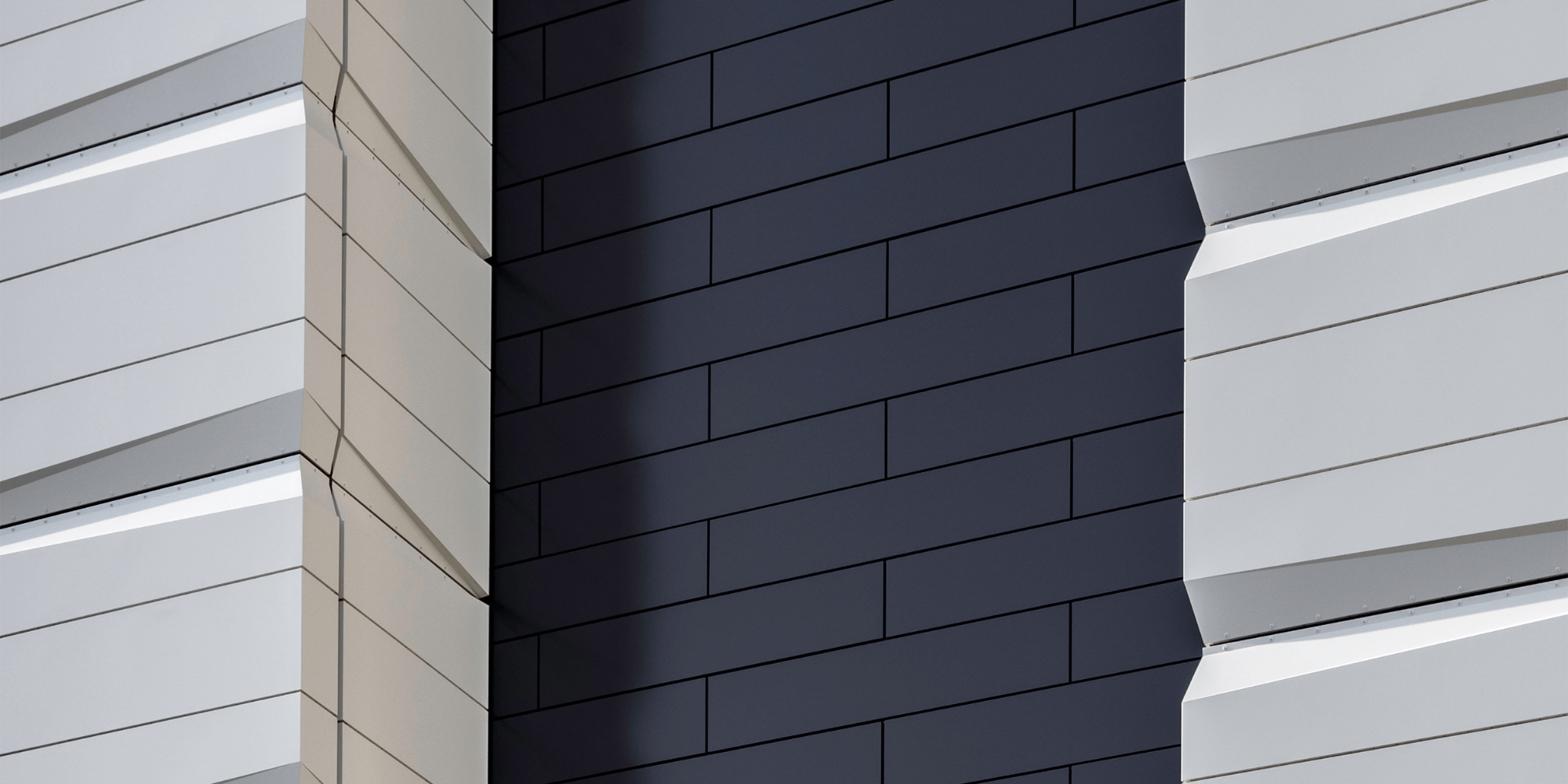

Material Options

From cladding, to integration, and components.