Insulation

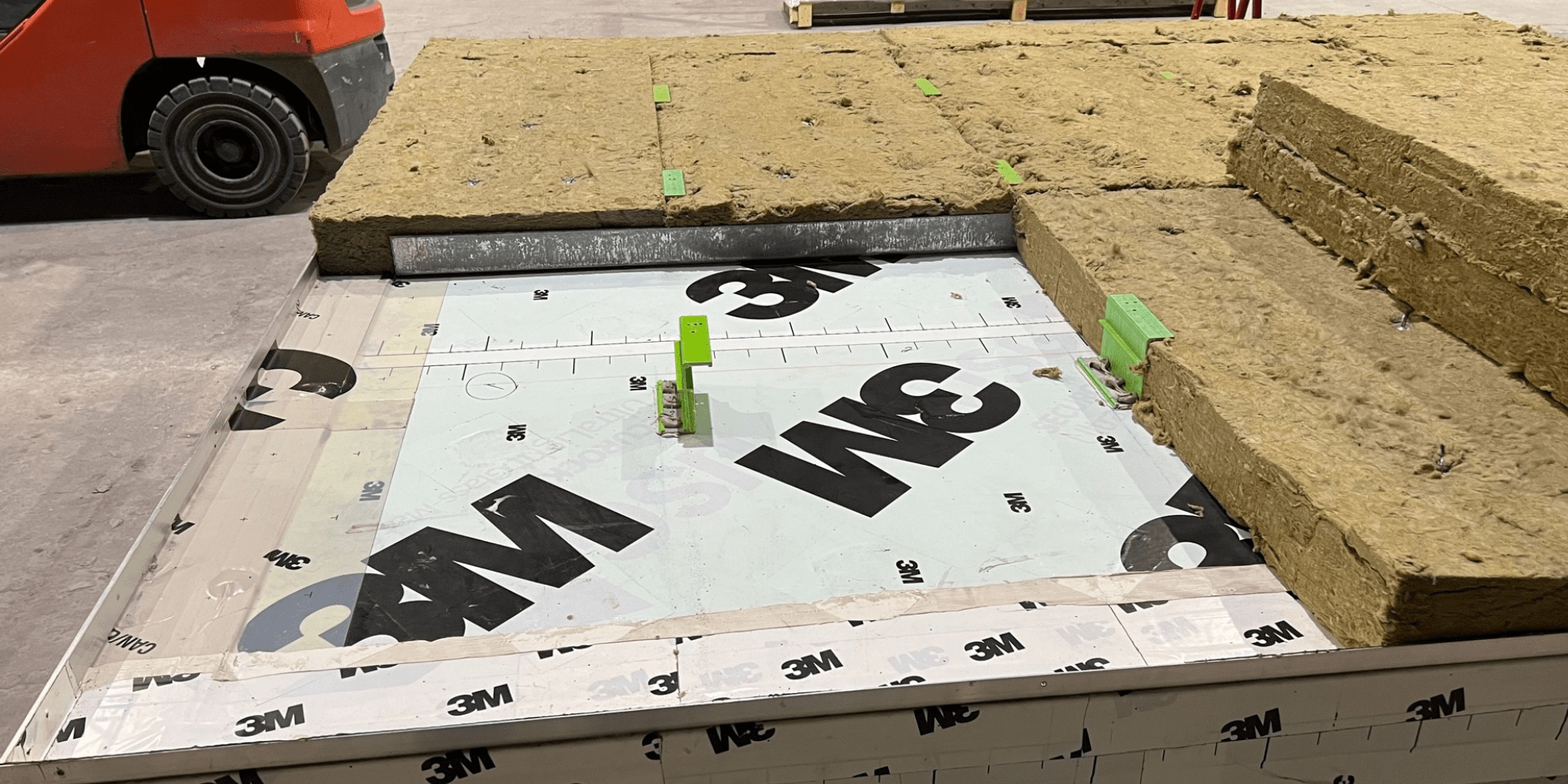

Insulation is the layer of our system responsible for thermal protection. Our systems utilize various types depending on system and project needs such as Polyisocyanurate (Polyiso) Boards, which is High R-value insulation offering excellent thermal resistance in a thin profile, mineral wool, which provides superior fire resistance, sound attenuation, and thermal performance, and Rigid Foam (XPS/EPS), which provides high R-value per inch and moisture resistance while providing significant compressive strength. EEWS’s systems can be designed to maximize energy efficiency, even to meeting the standards for a Passive House rating.

Need Fabrication Design Services?

Need something custom for your fabrication project? Contact us to discuss your project details.

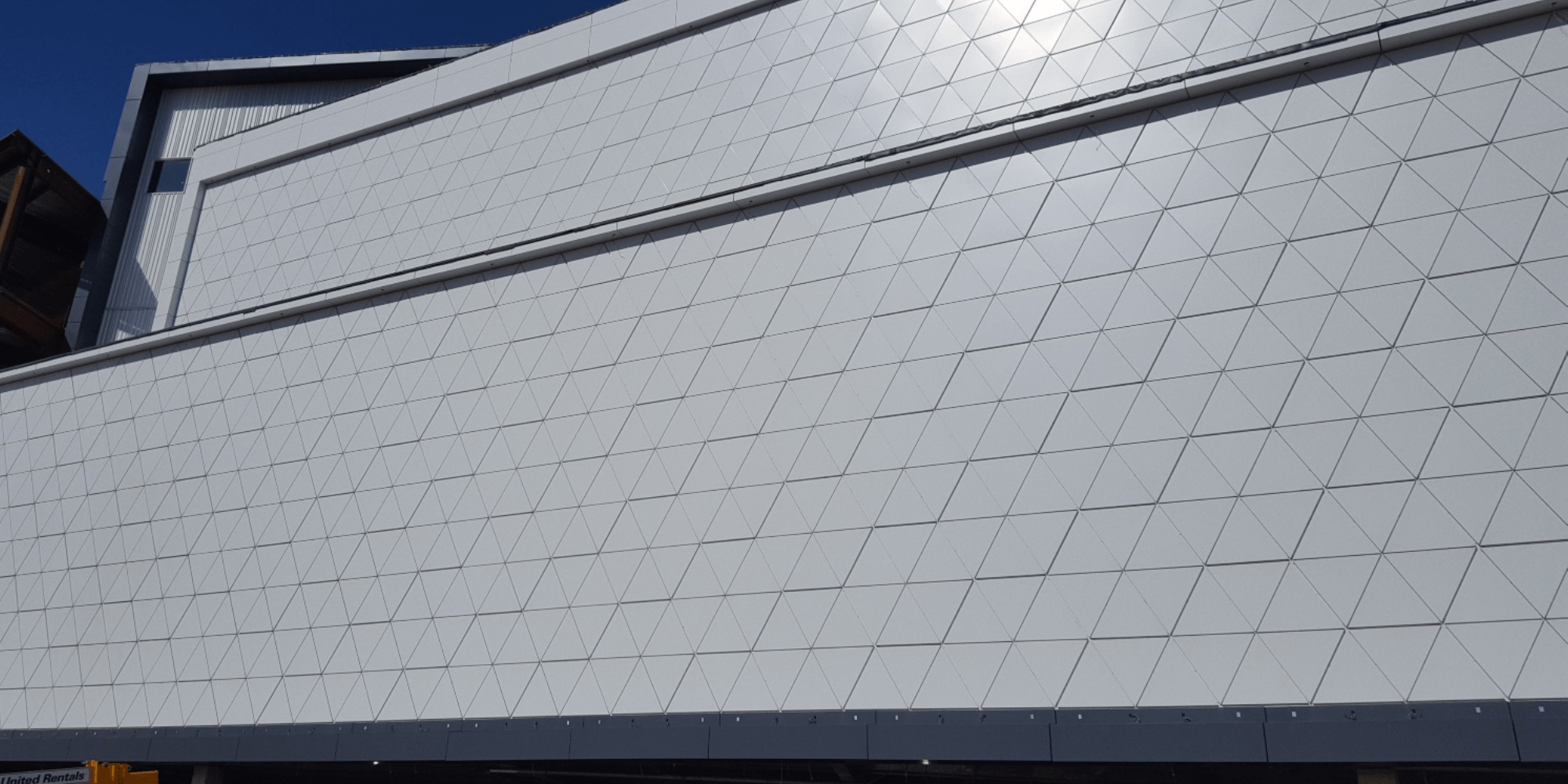

Insulation Integration

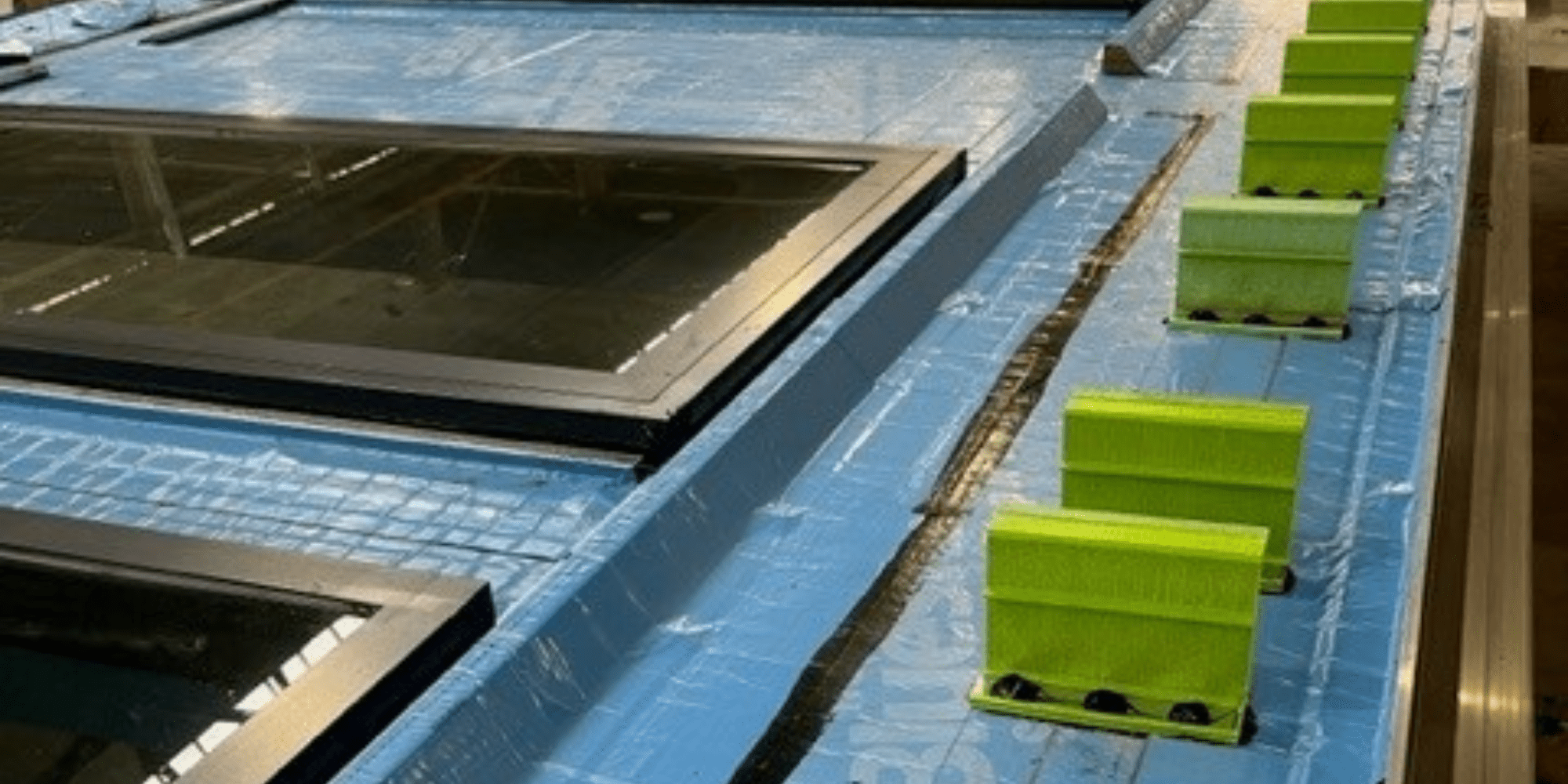

At EEWS, insulation is a core component of our wall panel systems, designed to ensure optimal thermal performance for every building envelope. We don’t treat insulation as an afterthought — it is fully engineered into each panel assembly to deliver continuous, uninterrupted protection against temperature fluctuations, energy loss, and moisture intrusion. By integrating insulation within the panel system itself, we help architects and owners meet stringent energy codes, enhance occupant comfort, and reduce long-term operational costs.

Types of Insulation

Our wall systems can accommodate a wide variety of insulation materials and assemblies based on project performance requirements and budget considerations, including:

- Polyisocyanurate (Polyiso) Boards: High R-value insulation offering excellent thermal resistance in a thin profile.

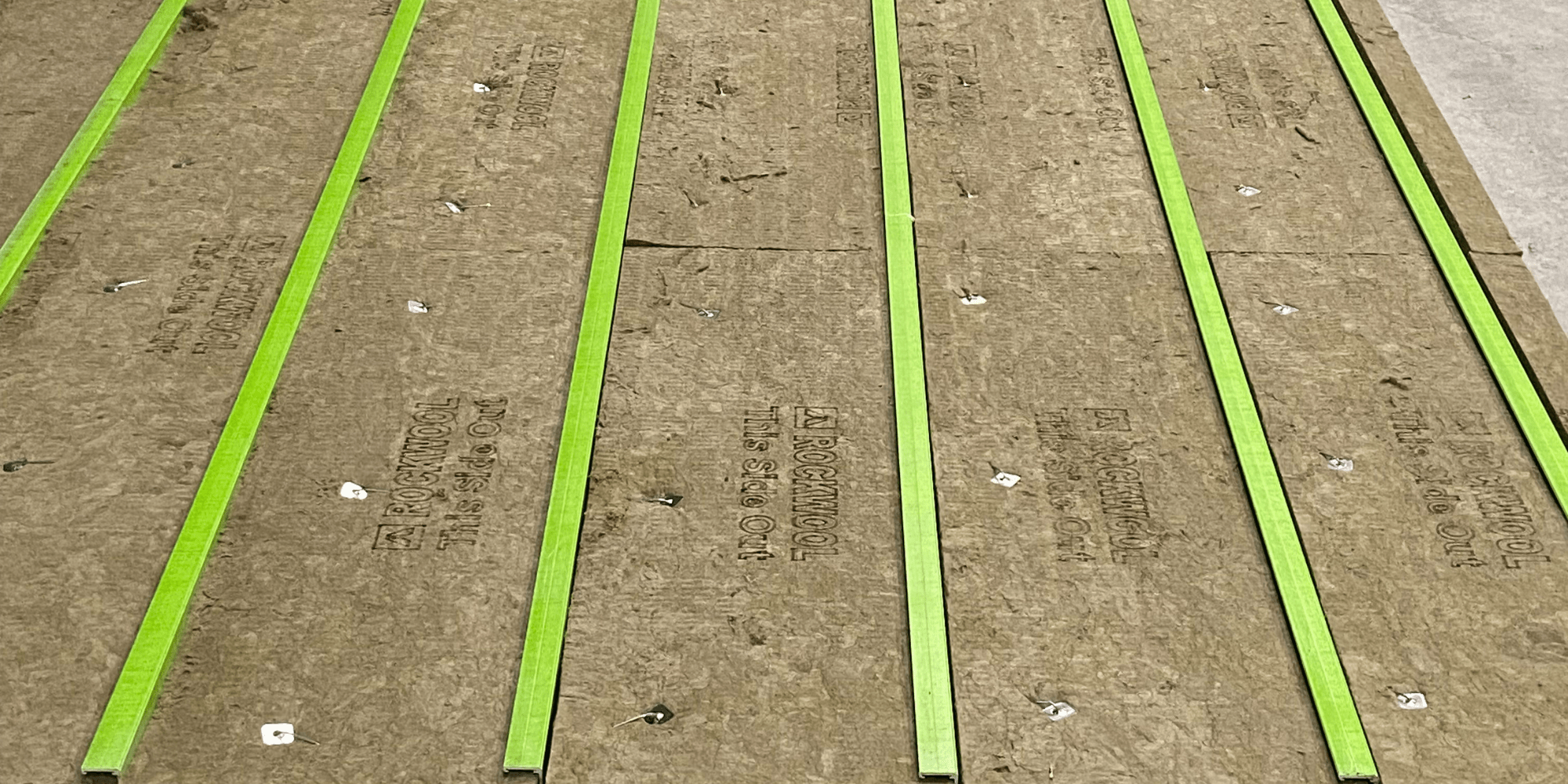

- Mineral Wool: Provides superior fire resistance, sound attenuation, and thermal performance.

- Rigid Foam (XPS/EPS): Lightweight options with high compressive strength and moisture resistance.

- Hybrid Systems: Combining materials to achieve enhanced fire, moisture, and thermal ratings.

Benefits of Integrated Insulation

Including insulation within the wall panel system delivers several key benefits:

- Continuous Insulation (CI): Reduces thermal bridging, providing a consistent thermal barrier across the entire façade.

- Improved Energy Efficiency: Supports compliance with evolving energy codes such as IECC, ASHRAE 90.1, and LEED standards.

- Reduced Installation Time: Factory-installed insulation minimizes on-site work, speeding up the building enclosure process.

- Enhanced Building Performance: Improved thermal performance leads to more stable interior environments and lower HVAC operating costs.

- Moisture Management: Integrated vapor barriers and weather-resistive barriers help protect the wall assembly from water intrusion and condensation.

Testing & Quality Assurance

Every insulated panel system we produce is subject to rigorous testing, including thermal performance modeling and real-world testing through full-scale mockups. Thermal imaging and condensation resistance evaluations help validate system performance before panels are fabricated and shipped to the job site. We ensure that our insulated panels maintain their integrity through the full lifecycle of the building, helping owners and developers protect their investment over the long term.

Customization & R-Value Flexibility

EEWS understands that different projects call for different thermal performance targets. We offer flexible insulation configurations to meet required R-values, whether you're aiming for baseline code compliance or targeting Net Zero energy goals. From standard commercial office buildings to high-performance institutional projects, we can customize panel thickness, material type, and insulation layering to achieve project-specific energy performance benchmarks.

FAQ

What types of insulation does EEWS offer?

What types of insulation does EEWS offer?

EEWS provides Polyisocyanurate (Polyiso) boards, mineral wool, rigid foam (XPS/EPS), and hybrid systems, tailored to meet diverse thermal and fire performance needs.

Why choose integrated insulation in wall panels?

Why choose integrated insulation in wall panels?

Integrated insulation ensures continuous thermal protection, reduces thermal bridging, and enhances energy efficiency, leading to lower HVAC costs.

Can EEWS customize insulation for specific R-values?

Can EEWS customize insulation for specific R-values?

Yes, EEWS offers flexible insulation configurations to meet project-specific R-value requirements, from basic code compliance to Net Zero targets.

What are the benefits of factory-installed insulation panels?

What are the benefits of factory-installed insulation panels?

Factory-installed insulation reduces on-site labor, accelerates construction timelines, and ensures consistent quality and performance.

How does EEWS ensure the quality of its insulation systems?

How does EEWS ensure the quality of its insulation systems?

EEWS conducts rigorous testing, including thermal performance modeling and full-scale mockups, to validate system integrity before deployment.

Maximizing The benefits Of Prefabrication

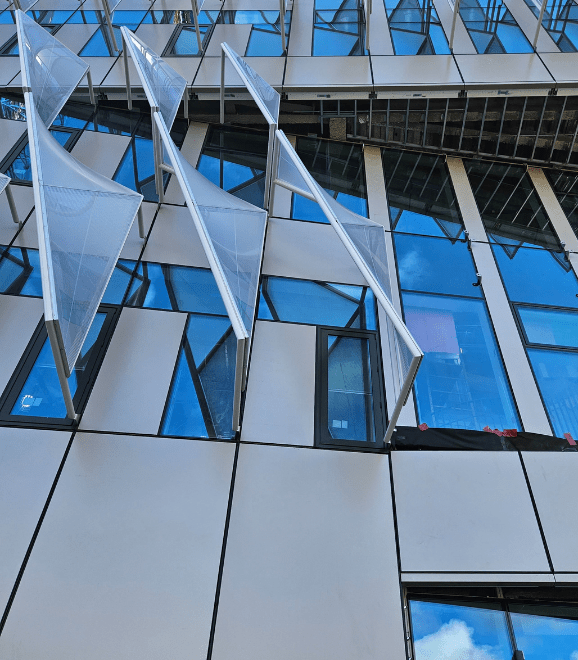

Design Assist

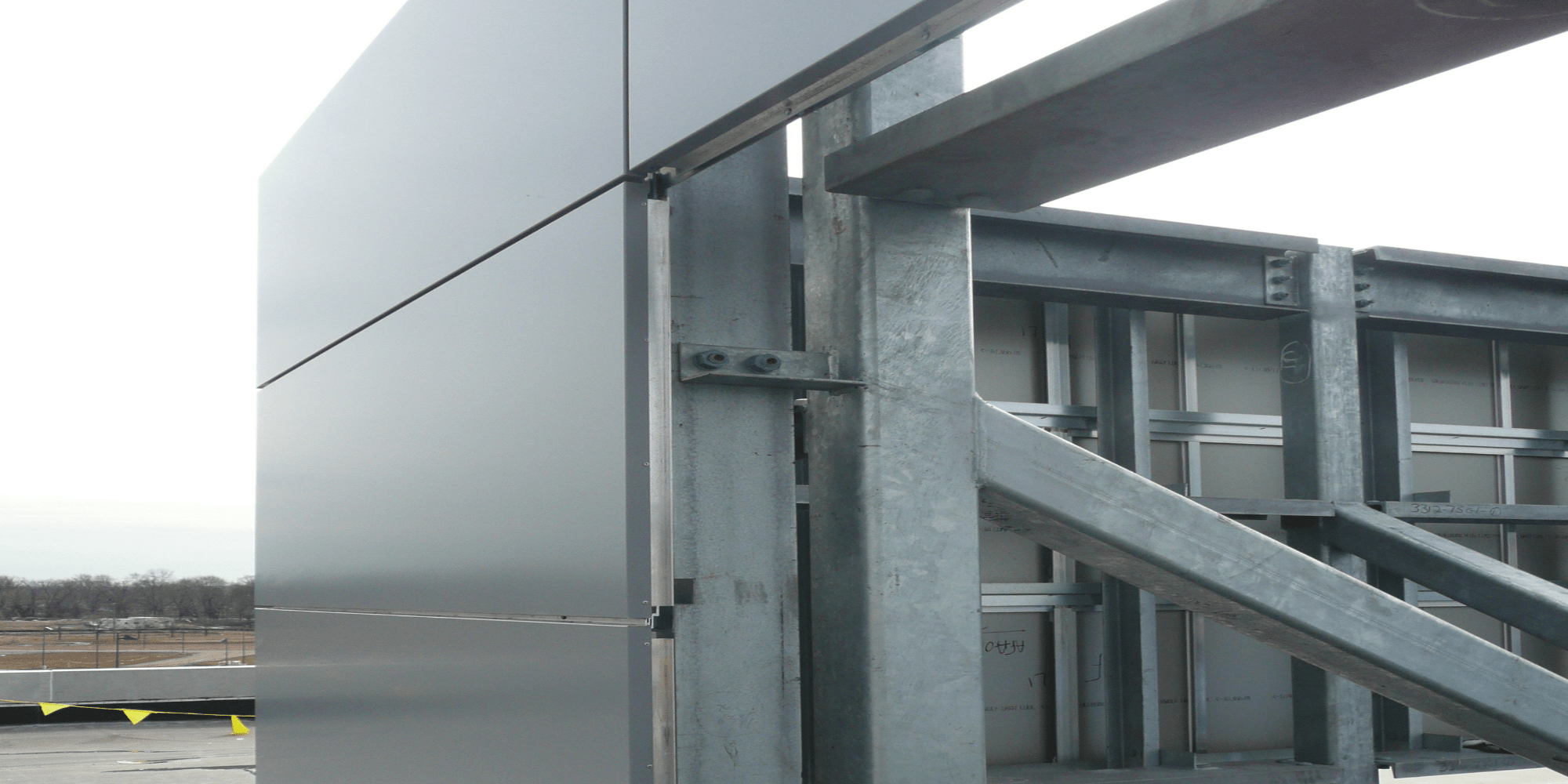

Our collaborative process unites one experienced team from design through installation. In-house Revit-certified designers ensure every detail is carefully planned and executed. Early alignment on goals and continuous design and budget feedback keep projects on track. This streamlined approach eliminates inefficiencies and delivers reliable, high-quality results.

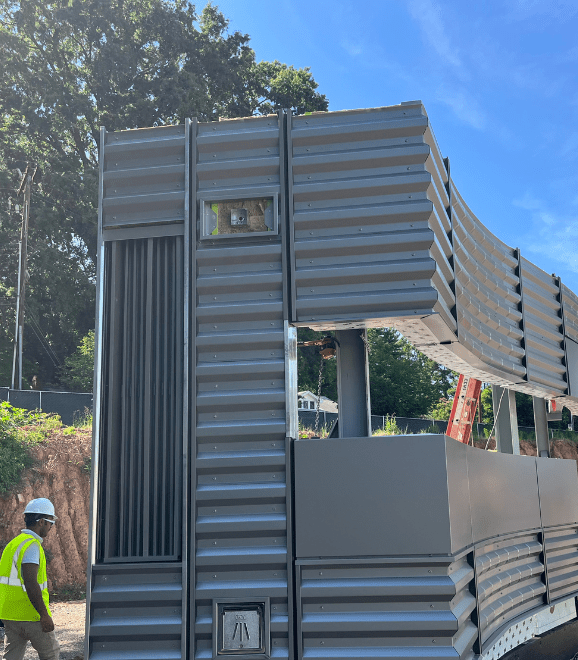

Safer Job Site

Our panelized enclosure system reduces on-site labor and shortens the project timeline, cutting labor costs. Pre-engineered and assembled off-site, it eliminates material storage, site congestion, and waste. Fewer trades are needed on-site, creating a cleaner, safer work environment. This streamlined process also lowers the risk of accidents and boosts site efficiency.

Quality Assurance

Our panelized systems provide superior thermal, moisture, and air performance through a continuous, high-quality enclosure. Assembled in a controlled facility, components like AVB, windows, and louvers are installed with precision. A single expert team handles multiple trades, reducing gaps and delays. This process also simplifies inspections and ensures consistent quality.

Building Enclosure Speed

Prefabricated panel systems greatly speed up the building enclosure process. Off-site fabrication in a controlled environment allows for faster dry-in and earlier interior work. This reduces weather delays and shortens the overall schedule. It’s an ideal solution for projects with tight timelines or phased occupancy.

Coordinated Engineered Interfaces Solutions

Our system features fully coordinated, engineered interfaces for seamless integration of all enclosure components. Key details are resolved during design and fabrication, avoiding on-site conflicts. This approach minimizes field adjustments and ensures consistent quality. The result is a unified, high-performing building envelope from day one.

Logistics

Prefabricated enclosure systems streamline logistics by reducing the volume of material delivered to and stored on-site. With just-in-time delivery and panels arriving in sequence, site congestion, waste, and handling are minimized. This controlled flow of materials supports cleaner, safer job sites and simplifies coordination among trades. The result is a more efficient, organized construction process that aligns with modern lean building practices.

Thermal Performance

When design allows, increasing opaque wall areas with prefabricated systems can greatly improve thermal performance. Fewer unitized joints enhance energy efficiency and air-tightness. These systems also offer broad cladding flexibility, giving architects more design freedom. In this case, the prefabricated enclosure is over four times more energy efficient than a traditional glass curtain wall.

Need Fabrication Services?

Need something custom for your fabrication project? Contact us to discuss your project details.

Material Options

From cladding, to integration, and components.