Terra Cotta

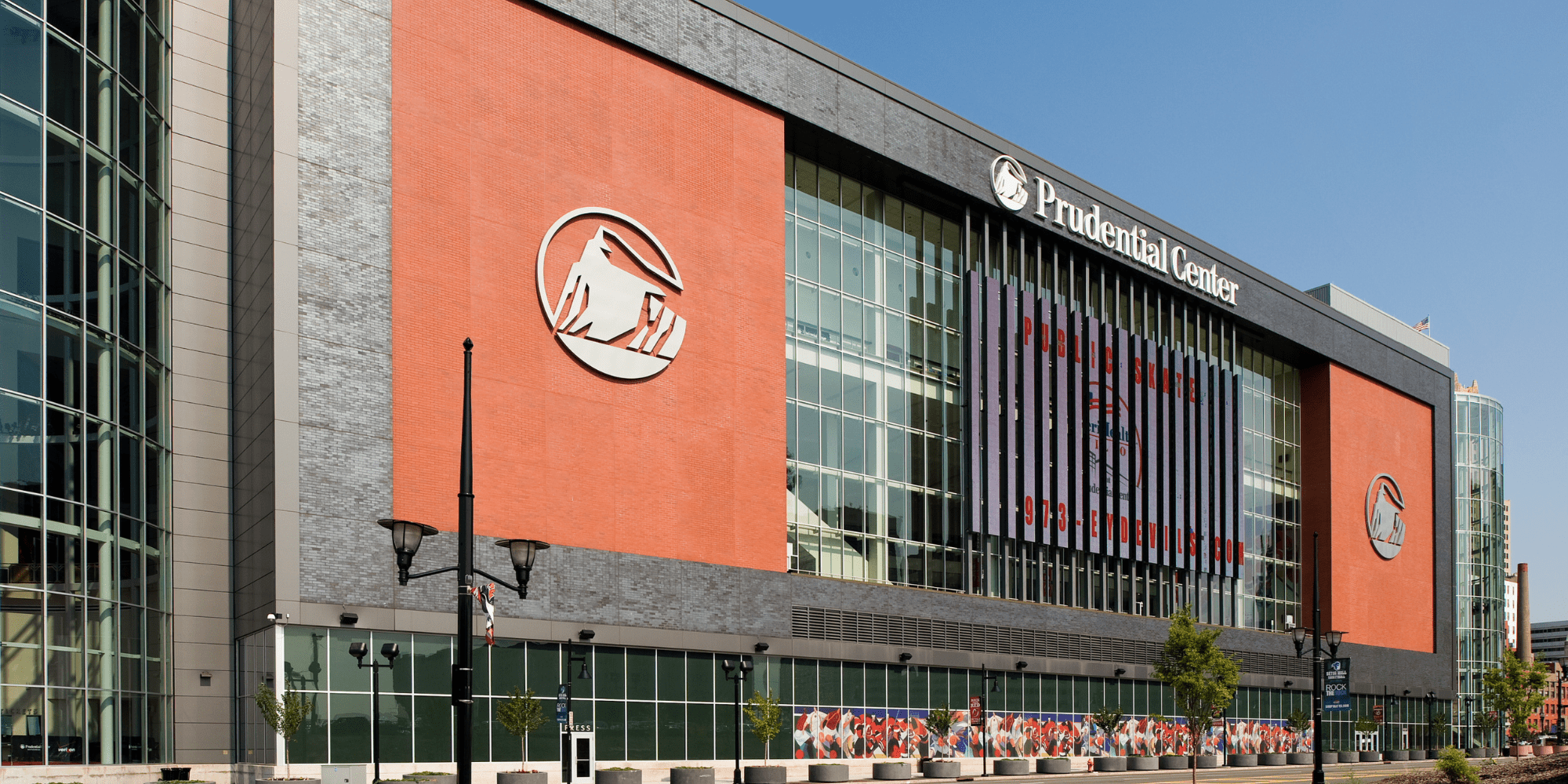

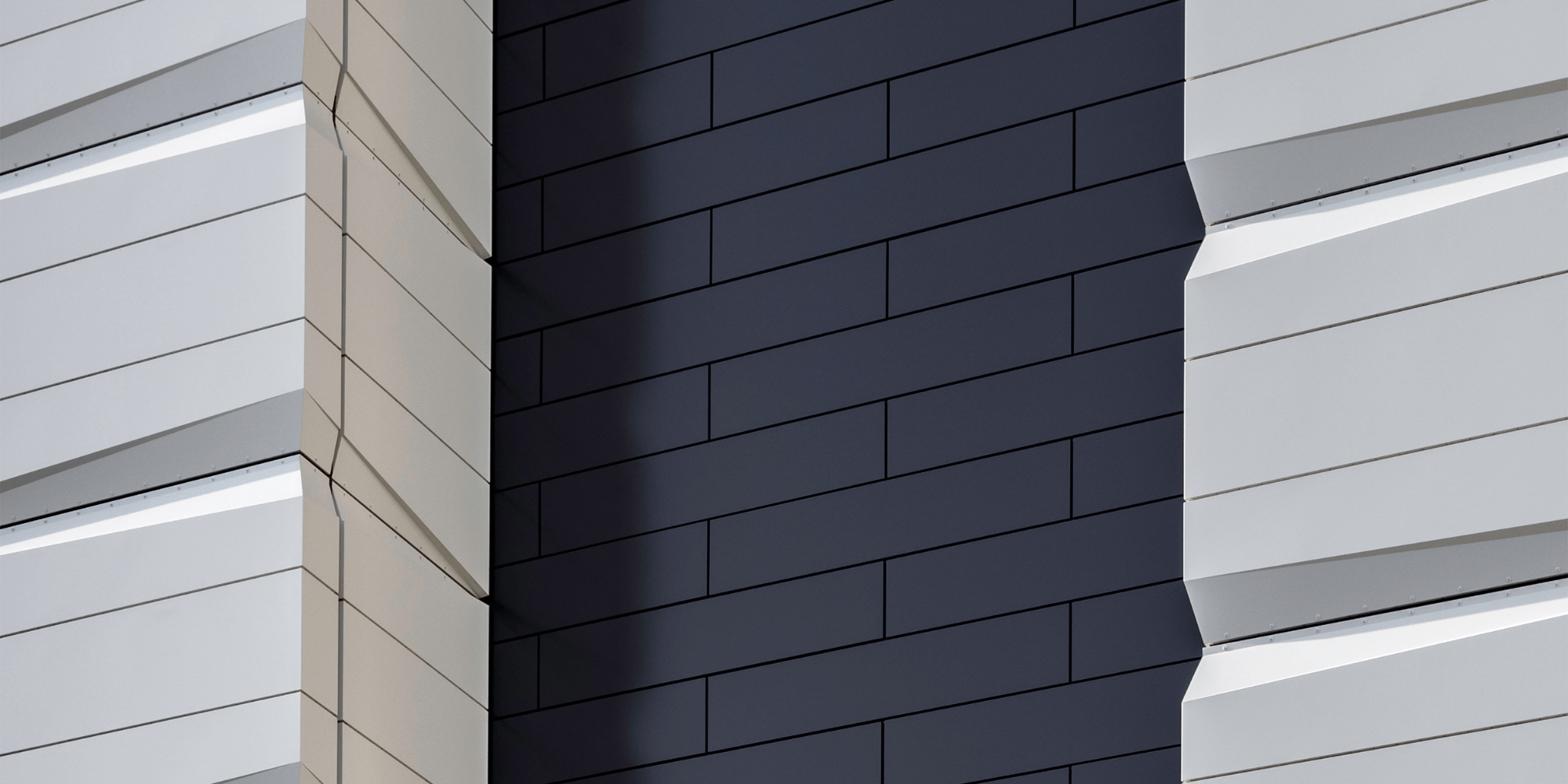

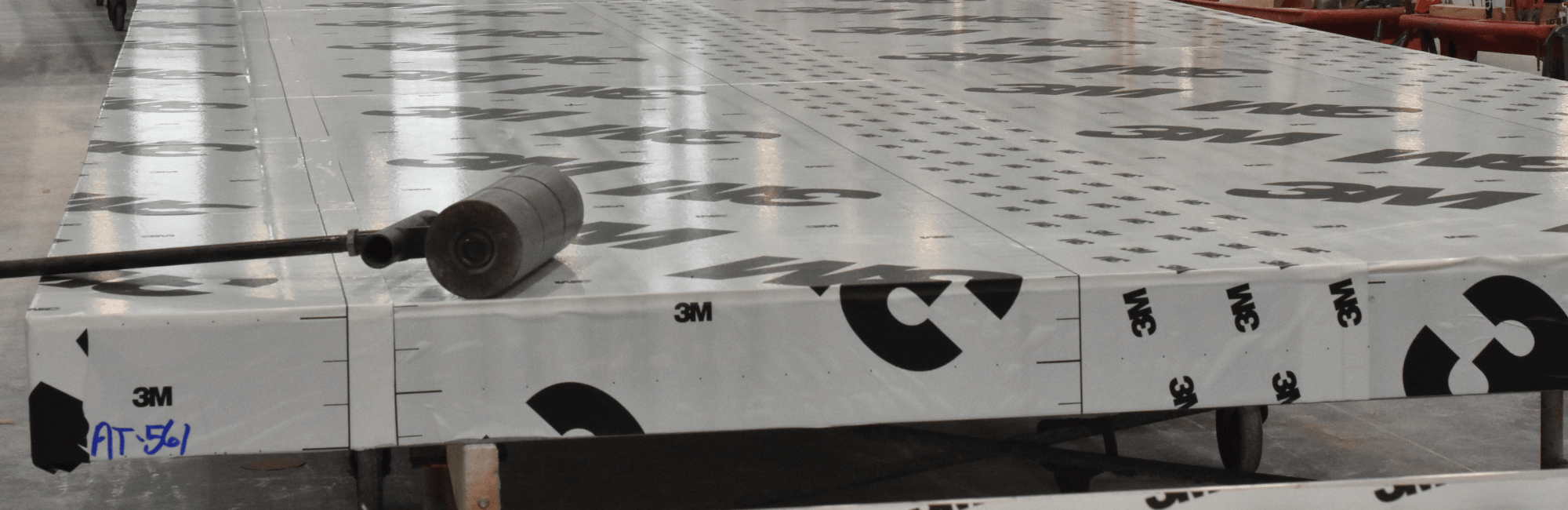

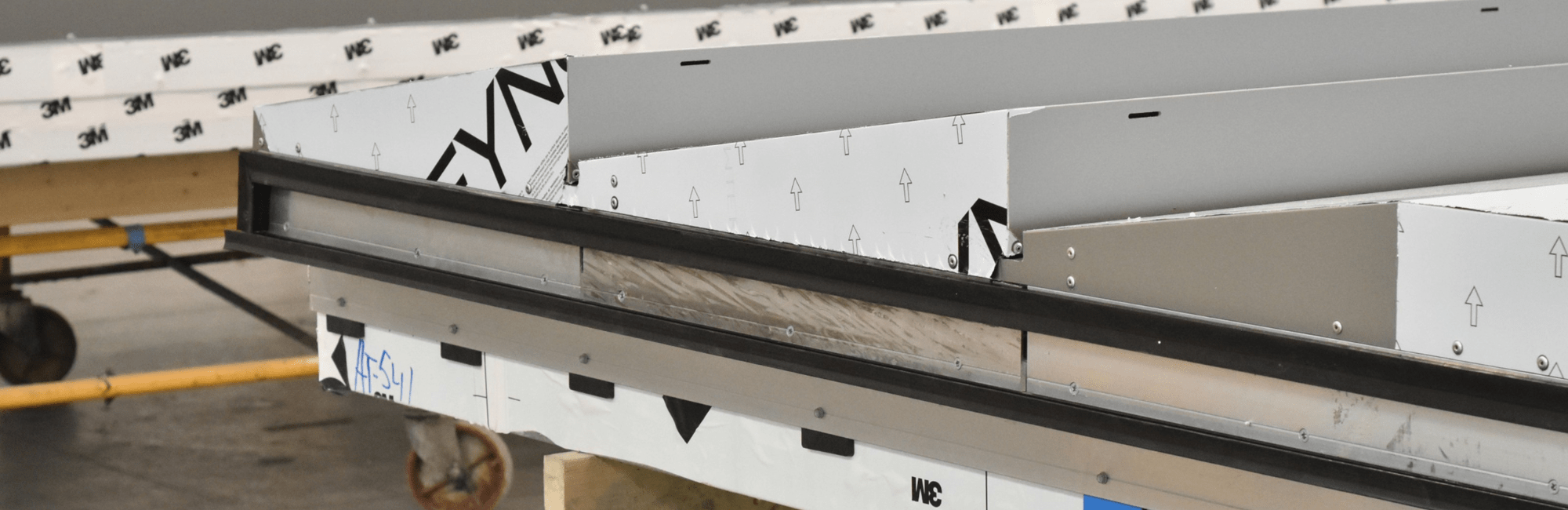

Terra cotta is a superior durable natural color-fast clay product available in both large and small formats of varying thickness depending on the application. EEWS engineers and fabricates the terra cotta systems using concealed aluminum or stainless steel girts, creating a ventilated pressure equalized rainscreen cavity preventing moisture from being drawn into the building. EEWS uses leading manufacturers including Shildan, Argeton, Boston Valley Terra Cotta, and Ludowici.

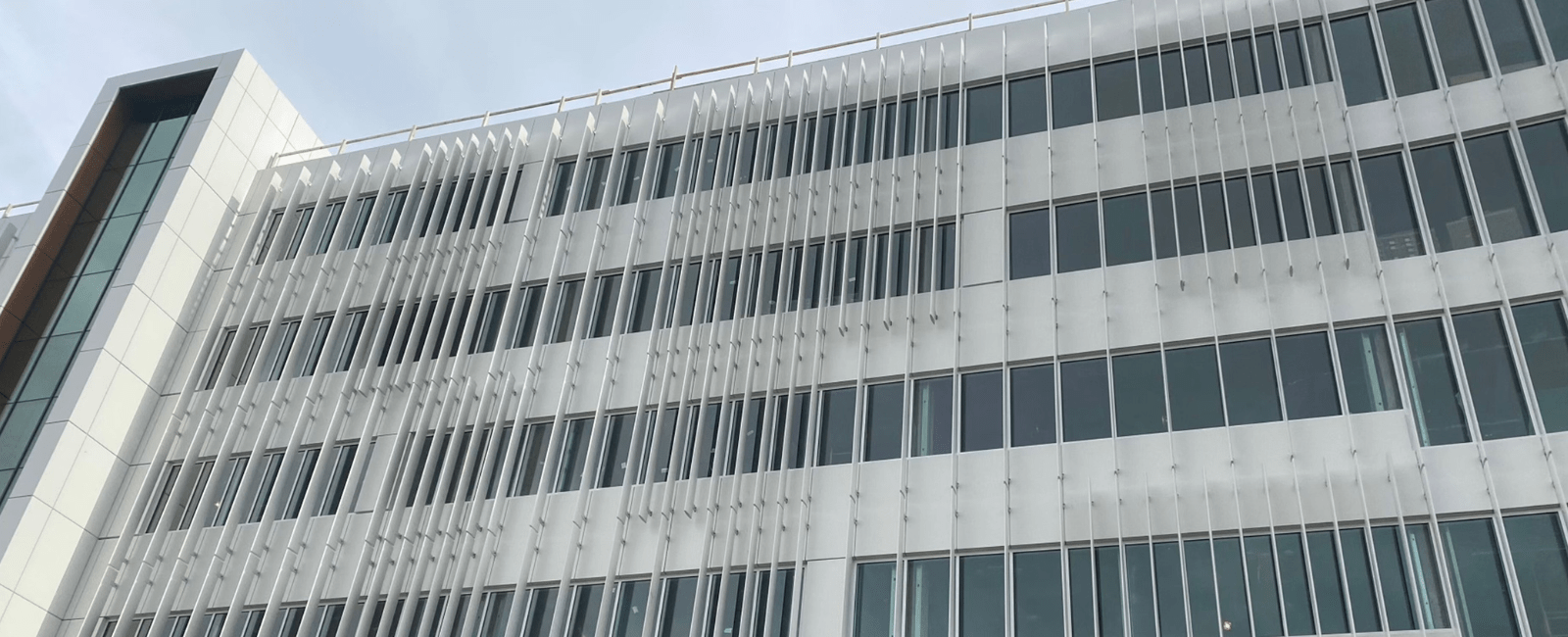

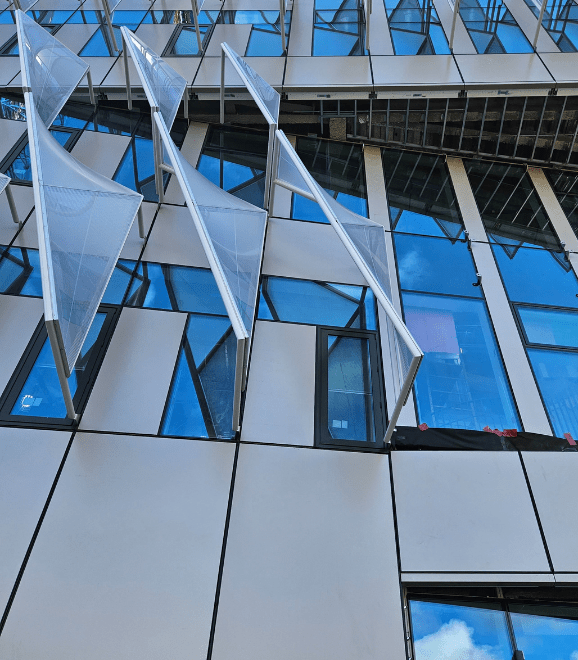

Pictured is the University of Pennsylvania, Philadelphia, PA ◊ 303 3rd Street, Cambridge, MA

FAQ

What is terra cotta cladding?

What is terra cotta cladding?

Terra cotta cladding is a façade system made from natural clay tiles. These tiles are fired to create a durable, colorfast exterior that enhances both modern and traditional architectural styles. They are known for their longevity and resistance to weathering.

How does the terra cotta rain-screen system work?

How does the terra cotta rain-screen system work?

The terra cotta rain-screen system functions as a pressure-equalized barrier. It prevents water intrusion by allowing air circulation behind the tiles, which aids in moisture management and thermal performance. This system is built on a galvanized steel frame with fiberglass-reinforced sheathing and an air/water barrier.

What are the benefits of using terra cotta tiles in building facades?

What are the benefits of using terra cotta tiles in building facades?

Terra cotta tiles offer several advantages:

Durability: Resistant to UV rays and weather conditions.

Aesthetic appeal: Provides a timeless and natural look.

Low maintenance: Requires minimal upkeep over time.

Sustainability: Made from natural clay, making it an eco-friendly choice.

Are terra cotta panels suitable for all climates?

Are terra cotta panels suitable for all climates?

Yes, terra cotta panels are designed to withstand various climatic conditions. Their thermal mass helps in energy efficiency, and the ventilated rain-screen system prevents moisture buildup, making them suitable for diverse environments.

How is the installation process of terra cotta cladding systems?

How is the installation process of terra cotta cladding systems?

Installation involves attaching the terra cotta tiles to a prefabricated panel system. The process includes:

Framing: Using light-gauge galvanized steel.

Sheathing: Applying fiberglass-reinforced panels.

Air/Water Barrier: Ensuring a sealed envelope.

Tile Attachment: Using concealed aluminum clips for a clean finish.

Can terra cotta cladding be customized for specific designs?

Can terra cotta cladding be customized for specific designs?

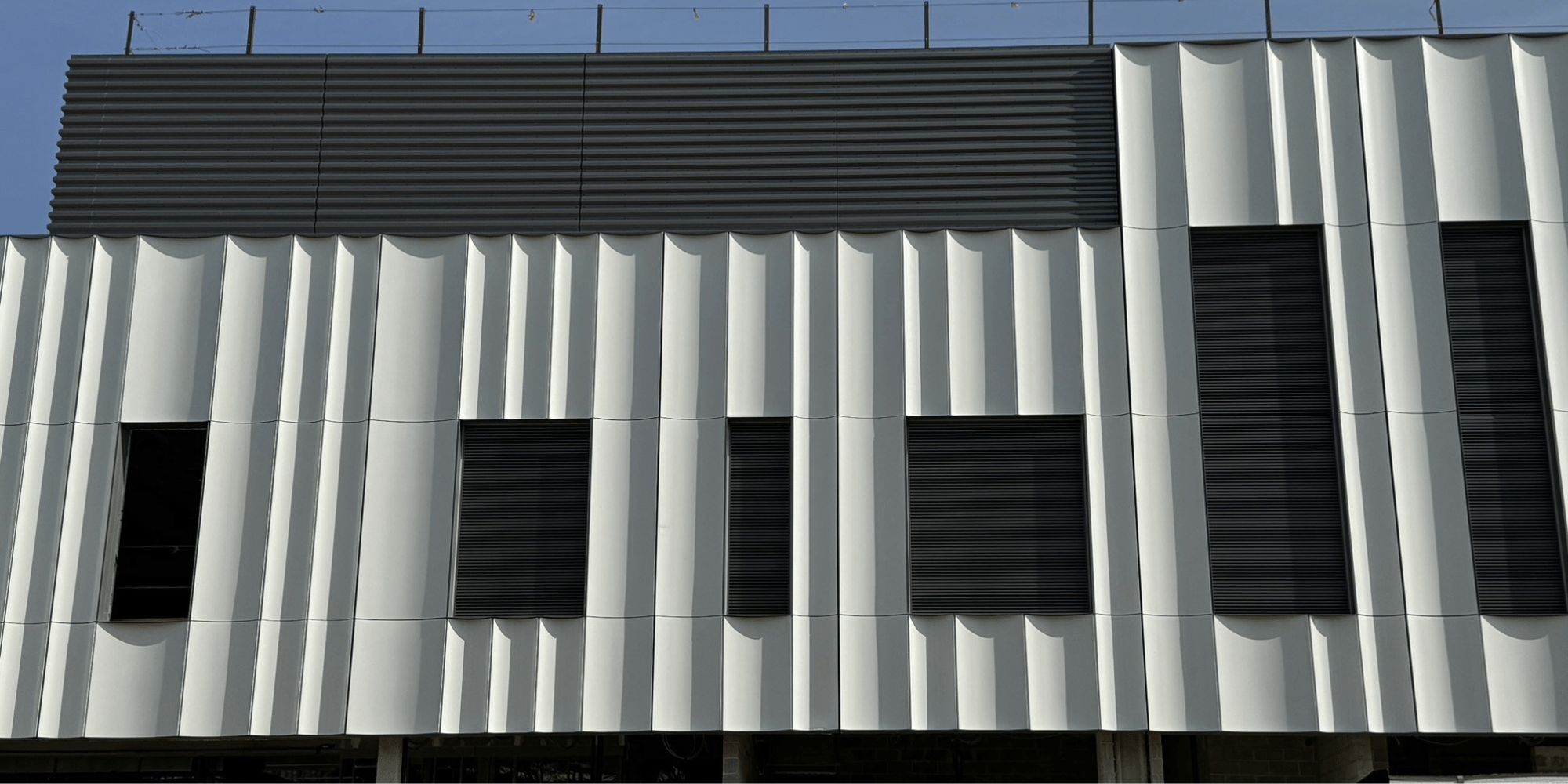

Absolutely. Terra cotta tiles can be manufactured in various shapes, sizes, and colors to meet specific architectural requirements, allowing for a high degree of customization in façade design.

Maximizing The benefits Of Prefabrication

Design Assist

Our collaborative process unites one experienced team from design through installation. In-house Revit-certified designers ensure every detail is carefully planned and executed. Early alignment on goals and continuous design and budget feedback keep projects on track. This streamlined approach eliminates inefficiencies and delivers reliable, high-quality results.

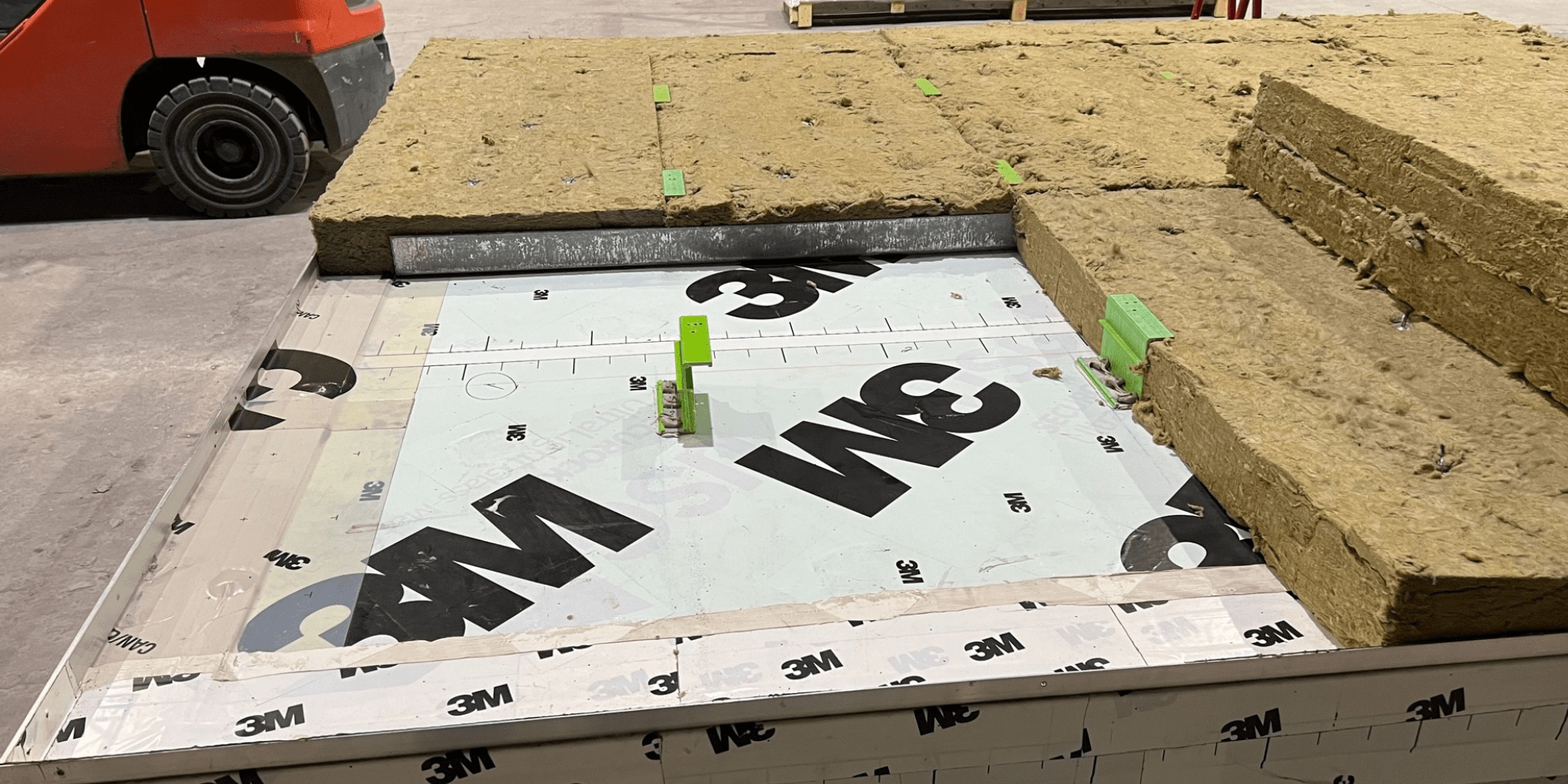

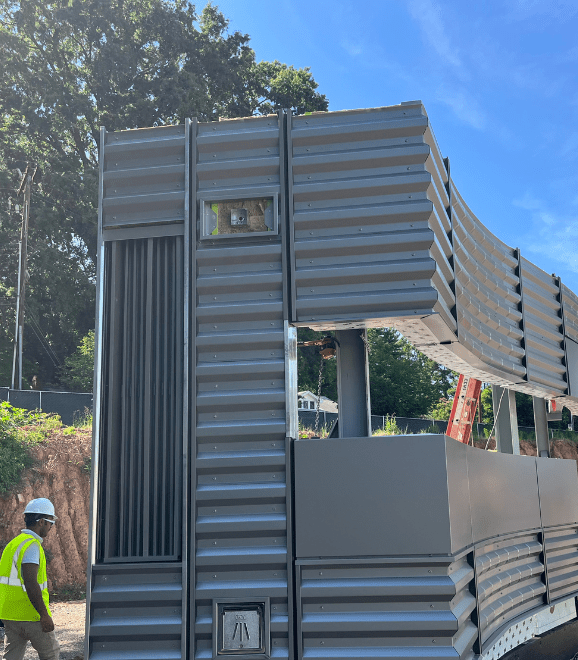

Safer Job Site

Our panelized enclosure system reduces on-site labor and shortens the project timeline, cutting labor costs. Pre-engineered and assembled off-site, it eliminates material storage, site congestion, and waste. Fewer trades are needed on-site, creating a cleaner, safer work environment. This streamlined process also lowers the risk of accidents and boosts site efficiency.

Quality Assurance

Our panelized systems provide superior thermal, moisture, and air performance through a continuous, high-quality enclosure. Assembled in a controlled facility, components like AVB, windows, and louvers are installed with precision. A single expert team handles multiple trades, reducing gaps and delays. This process also simplifies inspections and ensures consistent quality.

Building Enclosure Speed

Prefabricated panel systems greatly speed up the building enclosure process. Off-site fabrication in a controlled environment allows for faster dry-in and earlier interior work. This reduces weather delays and shortens the overall schedule. It’s an ideal solution for projects with tight timelines or phased occupancy.

Coordinated Engineered Interfaces Solutions

Our system features fully coordinated, engineered interfaces for seamless integration of all enclosure components. Key details are resolved during design and fabrication, avoiding on-site conflicts. This approach minimizes field adjustments and ensures consistent quality. The result is a unified, high-performing building envelope from day one.

Logistics

Prefabricated enclosure systems streamline logistics by reducing the volume of material delivered to and stored on-site. With just-in-time delivery and panels arriving in sequence, site congestion, waste, and handling are minimized. This controlled flow of materials supports cleaner, safer job sites and simplifies coordination among trades. The result is a more efficient, organized construction process that aligns with modern lean building practices.

Thermal Performance

When design allows, increasing opaque wall areas with prefabricated systems can greatly improve thermal performance. Fewer unitized joints enhance energy efficiency and air-tightness. These systems also offer broad cladding flexibility, giving architects more design freedom. In this case, the prefabricated enclosure is over four times more energy efficient than a traditional glass curtain wall.

Contact Us To Learn More

Need something custom for your fabrication project? Contact us to discuss your project details.

Material Options

From cladding, to integration, and components.