What Are Exterior Wall Panel Gaskets?

Exterior wall panel gaskets are elastomeric sealing components installed at the joints between prefabricated wall panels or between panels and other building elements (such as windows, doors, or structural framing). These gaskets are typically made from durable, weather-resistant materials such as EPDM rubber, silicone, or thermoplastic elastomers.

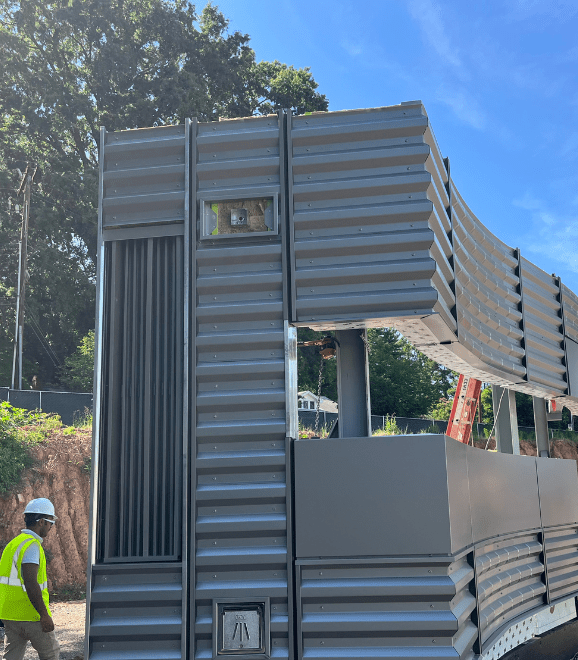

Unlike sealants, which are applied wet and require curing time, gaskets are pre-formed and installed dry, offering immediate sealing performance and reducing the risk of installation error. In prefabricated wall systems, gaskets are often pre-installed in the factory, ensuring a higher level of precision and quality control.

The Purpose of Gaskets in Prefabricated Wall Panels

Gaskets serve multiple purposes within exterior wall panel systems, all of which contribute to superior building envelope performance:

1. Air Sealing

Air leakage through joints in the building envelope can significantly degrade energy efficiency by allowing conditioned air to escape and unconditioned air to enter. Exterior wall panel gaskets create airtight seals at panel interfaces, helping to maintain consistent indoor temperatures and reduce HVAC energy consumption.

2. Water Resistance

Gaskets prevent rain, snow, and wind-driven moisture from entering the wall cavity, which can lead to mold, rot, and other forms of building degradation. When used alongside an Exterior Wall Panel Air & Vapor Barrier (AVB), they create a layered defense that ensures long-term water tightness.

3. Thermal Efficiency

By eliminating gaps and thermal leaks at joints, gaskets contribute to the continuity of the thermal envelope. This prevents thermal bridging and supports compliance with modern energy codes and green building certifications.

4. Noise and Vibration Control

In certain systems, gaskets can also serve as acoustic dampeners and vibration isolators, improving comfort in high-noise environments like urban settings or industrial zones.

Gaskets vs. Sealants: Why Gaskets Are Gaining Ground

While traditional wet-applied sealants still have a place in some construction applications, exterior wall panel gaskets offer significant advantages—especially in prefabricated systems where precision and durability are essential.

Advantages of Gaskets:

- Consistent thickness and compression across all joints

- Factory-installed for improved quality control

- No curing time—instant performance

- Resistant to shrinkage and cracking over time

- Easier to replace or maintain without damaging adjacent materials

With wet sealants, field conditions like temperature, humidity, and workmanship can all affect performance. Gaskets, on the other hand, are engineered and tested in controlled environments and perform reliably under a wide range of conditions.

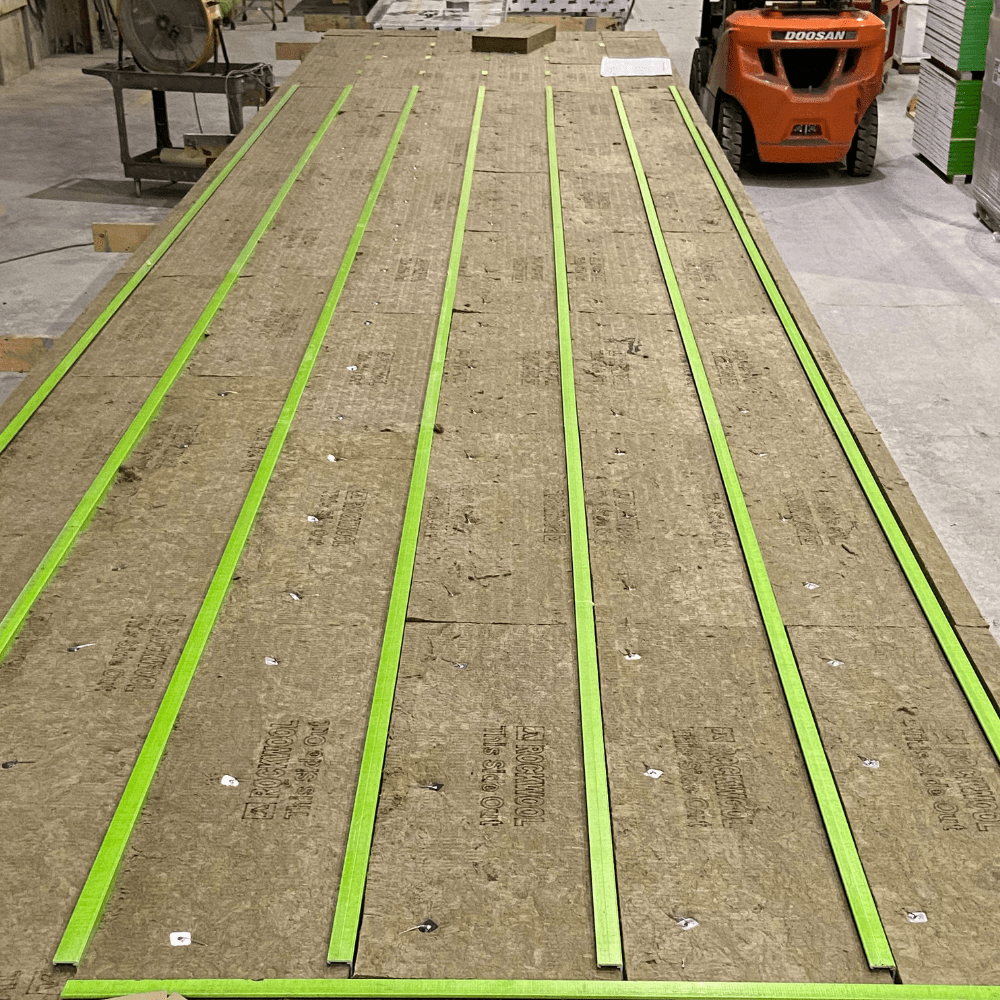

The Role of Gaskets in AVB Systems

An Exterior Wall Panel Air & Vapor Barrier (AVB) is a critical part of the building envelope, managing airflow, moisture migration, and vapor diffusion across the wall system. For an AVB system to be fully effective, it must be continuous across the entire façade—especially at joints between prefabricated panels.

This is where exterior wall panel gaskets become essential. They serve as the connective tissue between AVB layers, maintaining airtight and watertight continuity even as the building moves or settles over time.

Integration Strategies:

- Pre-applied gaskets embedded in panel edges align precisely with adjacent panels

- Compression gaskets ensure a tight seal with minimal clamping pressure

- Dual-seal configurations may include both a gasket and a sealant for redundancy

Gaskets are especially valuable in dynamic joints that experience thermal expansion, wind pressure, or structural deflection. Their flexibility and resilience allow them to maintain seal integrity without tearing or losing adhesion.

Gasket Placement in Prefabricated Wall Systems

In prefabricated exterior wall panels, gaskets can be strategically located at:

- Vertical and horizontal panel joints

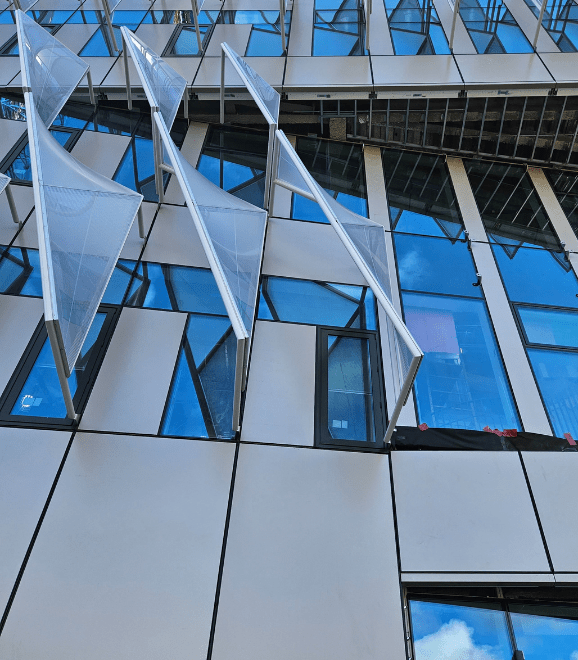

- Transitions between different materials (e.g., glass-to-metal)

- Panel-to-frame connections

- Perimeter joints around windows and doors

Gaskets are designed with specific shapes and compression profiles to match the geometry of the panel interface. Common profiles include bulb, blade, and D-shaped gaskets, each tailored to meet different sealing and movement requirements.

Durability and Maintenance of Gasket Systems

One of the greatest benefits of using exterior wall panel gaskets is their long-term durability. When properly installed, high-quality gaskets can last for decades without the need for reapplication, unlike sealants which may degrade or require re-caulking every few years.

Key Features of Durable Gasket Materials:

- UV resistance for sun-exposed façades

- Temperature flexibility to handle seasonal expansion and contraction

- Ozone and chemical resistance to withstand pollution and cleaning agents

- Compression set resistance to maintain shape and sealing force over time

Although gaskets are low-maintenance, they should still be inspected periodically—especially in areas with extreme environmental exposure or movement. Because gaskets are modular, replacing damaged sections is simple and cost-effective.

Meeting Energy and Code Requirements

Building codes and energy standards like IECC, ASHRAE 90.1, and LEED increasingly demand airtight building envelopes. Air leakage is not only a performance issue but a code compliance concern.

Exterior wall panel gaskets, when paired with a high-performance Exterior Wall Panel Air & Vapor Barrier (AVB), help meet or exceed these standards by:

- Sealing all envelope penetrations and joints

- Supporting blower door testing performance

- Enhancing envelope airtightness and moisture control

- Reducing energy consumption and improving thermal comfort

For developers and designers pursuing energy-efficient or passive building designs, gasketed panel systems provide an effective path toward envelope compliance and certification.

Conclusion

In an era where high-performance buildings must balance energy efficiency, moisture management, and aesthetic appeal, the smallest components often have the biggest impact. Exterior wall panel gaskets may be hidden behind cladding and finishes, but their role in weatherproofing is nothing short of essential.

By ensuring a continuous, flexible, and reliable seal between prefabricated exterior wall panels, gaskets enhance both the integrity and efficiency of the building envelope. When paired with a well-designed Exterior Wall Panel Air & Vapor Barrier (AVB), they form a comprehensive defense against the elements—delivering long-term performance, durability, and comfort.

Whether you’re building a high-rise, a healthcare facility, or a modular housing development, don’t overlook the importance of gaskets. In the quest for resilient, sustainable construction, they’re a small investment with big returns.