1. Sustainable Composite Cladding Takes Center Stage

One of the most prominent trends for 2025 is the rise of sustainable composite materials in exterior wall panels. Builders and architects are increasingly turning to recycled and bio-based materials that reduce carbon footprints without compromising strength or aesthetics.

Popular sustainable composite options include:

- Wood-plastic composites (WPC): Combining wood fibers with plastic polymers for a natural look and enhanced durability

- Recycled aluminum panels: Made from post-consumer waste, reducing raw material use and energy consumption

- Bio-resins and natural fiber panels: Using flax, hemp, or rice husk for renewable, low-impact finishes

These new exterior wall panel cladding materials offer a high-end aesthetic with an eco-conscious edge, aligning with green building certifications like LEED, WELL, and BREEAM.

When integrated into prefabricated exterior wall systems, these composites allow for rapid assembly while supporting net-zero energy and sustainability goals.

2. Smart Coatings and Adaptive Surfaces

Imagine cladding that reacts to the environment—changing color based on sunlight, resisting dirt and pollutants, or even generating electricity. In 2025, this is no longer a futuristic vision; smart coatings and adaptive materials are becoming a reality in exterior wall design.

Key innovations include:

- Photocatalytic coatings: Break down pollutants and organic matter on the panel surface using UV light, reducing maintenance needs

- Thermochromic finishes: Shift color or reflectivity in response to temperature changes, enhancing thermal performance

- Self-healing materials: Microcapsules within the coating release resins that fill cracks automatically

- Solar-integrated cladding: Panels with built-in photovoltaic (PV) layers that generate clean energy while protecting the façade

These materials not only enhance the functionality of exterior wall panel cladding materials, but also add an extra layer of value to prefabricated exterior wall systems, where performance and innovation must go hand-in-hand.

3. Ultra-Durable and Low-Maintenance Finishes

Durability and ease of maintenance remain high priorities in 2025, especially for commercial, healthcare, and high-rise residential projects. The latest generation of exterior wall panel cladding materials is engineered to withstand harsh climates, UV exposure, corrosion, and impact.

Trending materials include:

- Fiber cement panels: Resistant to fire, moisture, and pests with virtually no maintenance required

- High-pressure laminates (HPL): Highly durable and customizable, now available with enhanced UV resistance

- Engineered stone panels: Offering the look of granite or marble with reduced weight and increased durability

- Powder-coated aluminum or steel: Long-lasting colors and finishes with low environmental impact

These materials are ideal for prefabricated exterior wall systems, where low-maintenance design is critical for long-term performance and life-cycle cost reduction.

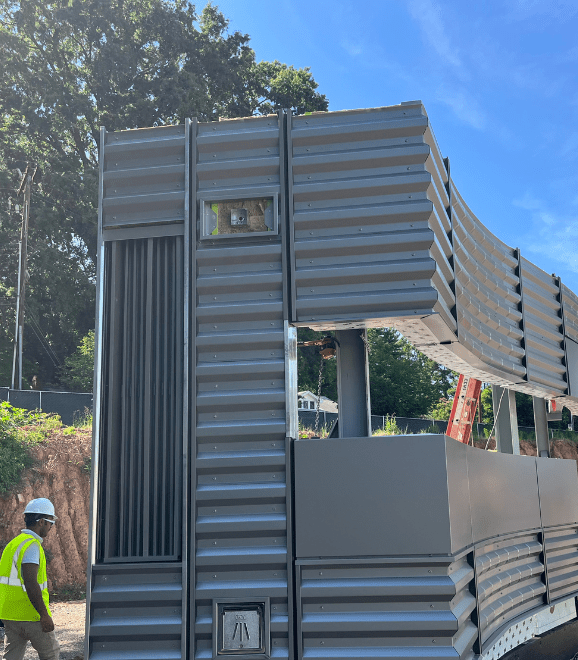

4. Textured and 3D Surface Designs

While minimalism still holds sway in some markets, 2025 is seeing a resurgence of texture, depth, and dimension in façade design. Architects are using exterior wall panel cladding materials not just to protect buildings—but to tell a story.

Popular design trends include:

- 3D profiles and geometries: Cladding panels with depth, angles, or curves that create movement and shadow

- Textured finishes: Stone, wood grain, concrete, or metal textures that add tactile and visual interest

- Parametric patterns: CNC-cut or laser-engraved designs that offer custom artistic expression

Digital fabrication techniques allow these features to be efficiently integrated into prefabricated exterior wall systems, expanding creative possibilities without adding cost or complexity on-site.

5. Natural and Raw Material Aesthetics

As biophilic design continues to gain momentum, 2025 sees a rise in demand for natural materials—or at least materials that look natural. The warmth and texture of wood, the rugged appeal of stone, and the raw elegance of concrete are all finding new expression in exterior wall panel cladding materials.

What’s trending:

- Thermally modified wood: Real wood treated for longevity and dimensional stability

- Stone veneers: Lightweight alternatives to full stone with the same timeless aesthetic

- Concrete-look panels: Fiber cement or GFRC (glass fiber reinforced concrete) with industrial appeal

- Weathered metal finishes: Corten steel or metal panels that develop a protective patina over time

These materials are frequently used in prefabricated exterior wall systems to create a natural, organic feel without compromising performance or constructability.

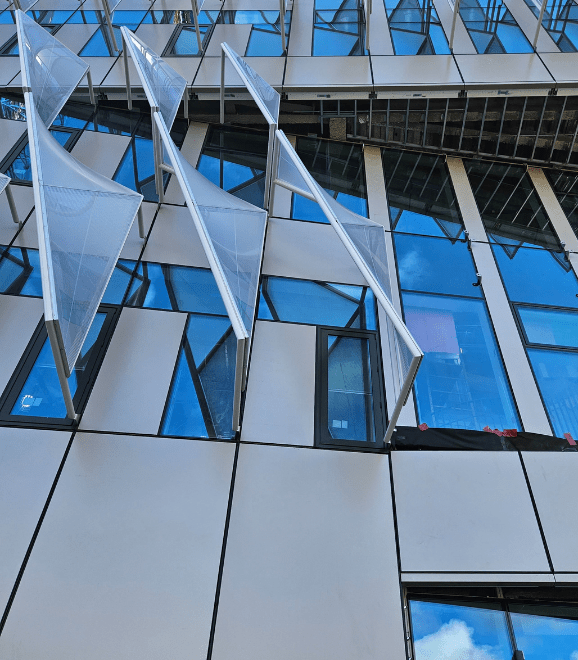

6. Mixed-Material Façades

In 2025, it’s not just about choosing one cladding material—it’s about how you combine multiple materials to create contrast, hierarchy, and depth. Designers are increasingly blending different textures and finishes to create visually dynamic façades.

Popular combinations:

- Metal with wood (warm + industrial)

- Glass with fiber cement (sleek + textured)

- Stone with aluminum (solid + modern)

- HPL with brick veneer (colorful + classic)

Prefabricated exterior wall systems excel at handling these mixed-material applications. By engineering transitions and interfaces in the factory, manufacturers ensure smooth installations and long-term durability while delivering bold architectural statements.

7. Customization and Digital Fabrication

Thanks to digital design tools and advanced manufacturing technologies, 2025 is the year of mass customization. Architects can now specify custom panel sizes, patterns, textures, and finishes—without the delays or cost premiums of the past.

Using CNC routers, robotic arms, and BIM-integrated workflows, manufacturers can produce exterior wall panel cladding materials that precisely match a designer’s vision. These panels can then be incorporated directly into prefabricated exterior wall systems, ensuring fast, flawless field installation.

This level of customization enables everything from company branding to cultural motifs to be embedded directly into the building skin—creating unique experiences for occupants and visitors alike.

Conclusion: A New Era for Exterior Cladding

As we move deeper into 2025, the cladding industry is no longer just about protecting a building—it’s about defining it. The most forward-thinking exterior wall panel cladding materials now offer a powerful combination of design freedom, sustainability, performance, and longevity.

And when paired with prefabricated exterior wall systems, these materials empower architects and builders to deliver projects that are faster, greener, and more innovative than ever before.

Whether you’re focused on net-zero performance, distinctive design, or long-term durability, staying ahead of cladding trends will ensure your next project stands out—in all the right ways.