What Is Exterior Wall Panel Sheathing?

Exterior wall panel sheathing is the rigid panel material installed between the structural framing and the outer cladding of a building. It serves several key purposes:

- Structural support

- Wind and seismic load resistance

- Nailing base for cladding and finishes

- Surface for air and water barrier applications

- Improved insulation and energy performance

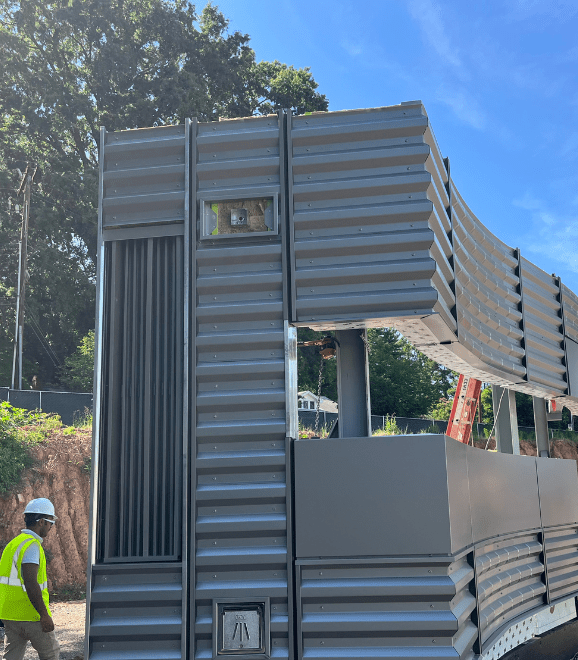

In the context of prefabricated exterior wall systems, sheathing is typically applied in the factory as part of the complete wall assembly. This integration not only improves quality control but also accelerates onsite construction by eliminating the need for additional sheathing installation.

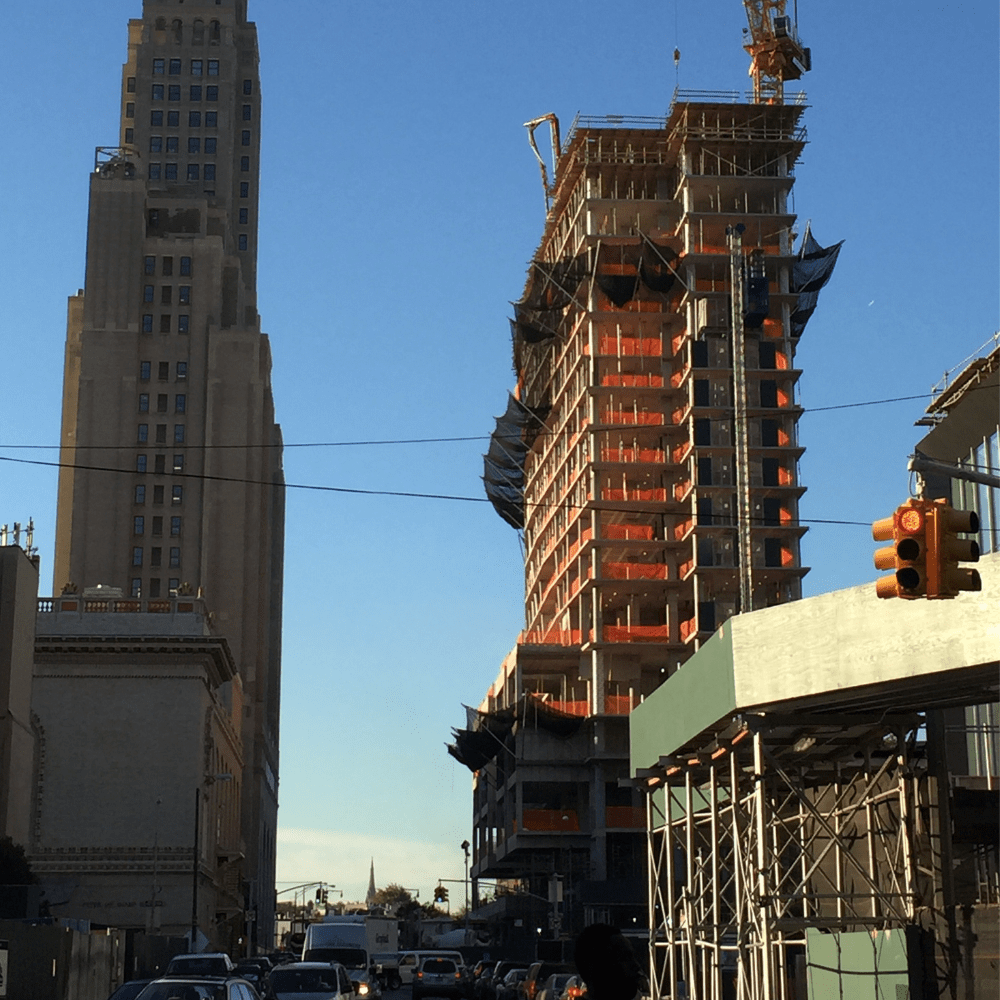

The Role of Sheathing in Prefabricated Wall Systems

In prefabricated exterior wall systems, wall panels are manufactured off-site in a controlled environment and shipped to the construction site for quick assembly. Within these panels, exterior wall panel sheathing plays a critical role in providing the structural rigidity needed to transport, lift, and install the panels safely.

Furthermore, because prefabrication allows for tight tolerances and uniform production, the use of sheathing ensures a flat, stable surface for applying other building envelope layers, such as vapor barriers, insulation, or cladding. It also helps panels meet or exceed building code requirements for wind loads and seismic forces.

Common Sheathing Materials: Comparison and Benefits

Selecting the right sheathing material is essential for achieving the desired performance characteristics. Each sheathing type has distinct strengths, and the choice depends on factors like climate, structural requirements, cost, and project type.

1. Oriented Strand Board (OSB)

Strength: ★★★★☆

Moisture Resistance: ★★★☆☆

Cost-Effectiveness: ★★★★★

OSB is one of the most widely used exterior wall panel sheathing materials, known for its affordability and structural performance. Manufactured from compressed wood strands and resin, OSB provides good shear strength, making it suitable for both residential and commercial wall panels.

Pros:

- Cost-effective and widely available

- Uniform strength and stiffness

- Suitable for structural bracing

- Compatible with vapor barriers and weather-resistive barriers (WRBs)

Cons:

- Vulnerable to moisture swelling if not properly sealed

- Heavier than plywood

Best for: Budget-conscious projects that require strong structural support within prefabricated exterior wall systems.

2. Plywood

Strength: ★★★★★

Moisture Resistance: ★★★★☆

Cost-Effectiveness: ★★★☆☆

Plywood has long been a trusted material in construction due to its strength and durability. Composed of cross-laminated veneer layers, plywood offers excellent resistance to cracking and warping under load.

Pros:

- Excellent nail and screw holding capacity

- Stronger in shear and better impact resistance than OSB

- Performs well in humid or high-moisture climates

Cons:

- More expensive than OSB

- Limited availability in some markets

Best for: Projects requiring high structural performance or located in wet climates where durability is paramount.

3. Glass-Mat Gypsum Sheathing

Strength: ★★★☆☆

Moisture Resistance: ★★★★★

Cost-Effectiveness: ★★★★☆

Glass-mat gypsum sheathing is increasingly common in commercial prefabricated exterior wall systems, especially in projects that prioritize fire resistance and moisture control. Composed of a moisture-resistant gypsum core faced with fiberglass mats, it offers excellent mold and mildew resistance.

Pros:

- Non-combustible and fire-rated

- High resistance to mold and moisture

- Lightweight and easy to handle

- Ideal substrate for air/vapor barriers

Cons:

- Lower structural strength—typically used in non-load-bearing walls or with supplemental bracing

- Requires careful handling to prevent edge damage

Best for: Hospitals, schools, multifamily housing, and other commercial buildings that demand non-combustible components and robust moisture protection.

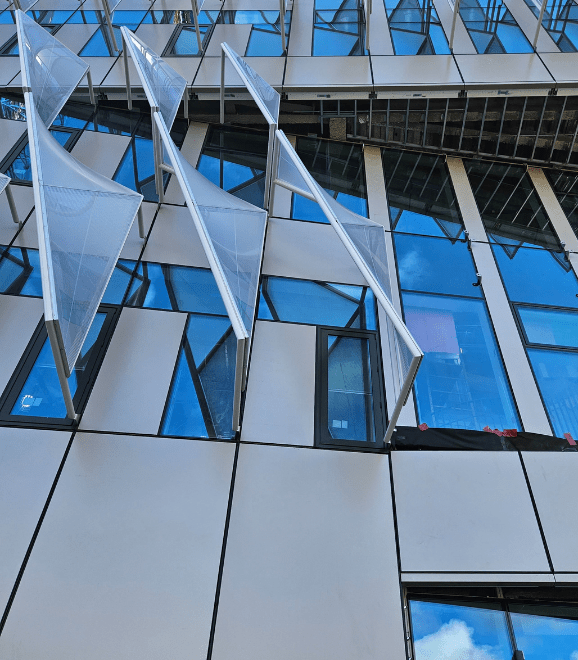

Sheathing and Weather Resistance

One of the key functions of exterior wall panel sheathing is to serve as a base for air and moisture control layers. Some sheathing products even come with integrated water-resistant barriers (WRBs) to simplify installation and reduce labor.

In prefabricated exterior wall systems, WRB-integrated sheathing helps streamline construction by minimizing the need for field-applied membranes. This reduces weather delays and improves long-term building performance by ensuring a more reliable moisture barrier.

Whether applied separately or integrated into the panel, the weather-resistive layer must be compatible with the sheathing material to maintain effective protection against wind-driven rain and vapor intrusion.

Sheathing and Structural Performance

In addition to weather resistance, exterior wall panel sheathing provides shear resistance to lateral loads, helping buildings withstand wind and seismic forces. Panels are typically fastened to framing with nails or screws at specified intervals to meet code-mandated shear values.

For shear wall applications, OSB and plywood remain the go-to choices, with plywood often favored in high-load scenarios due to its superior structural properties. Gypsum sheathing, while not structurally strong on its own, may be used alongside metal framing and bracing systems in non-structural panel applications.

Sustainability Considerations

As sustainability becomes a central theme in construction, the choice of sheathing material can influence a project’s environmental impact. Many prefabricated exterior wall systems now incorporate materials that meet green building standards, such as:

- FSC-certified plywood and OSB from responsibly managed forests

- Recycled content in gypsum-based panels

- VOC-compliant adhesives and coatings

- Energy-efficient panel design that reduces thermal bridging and improves envelope performance

Selecting the right exterior wall panel sheathing not only contributes to energy code compliance but also supports LEED and other green building certifications.

Conclusion

While it may go unnoticed beneath layers of cladding and insulation, exterior wall panel sheathing is one of the most important components in any wall system—especially in prefabricated exterior wall systems, where structural precision and moisture control are critical to performance.

By understanding the roles and benefits of different sheathing materials—OSB, plywood, and gypsum—you can make informed decisions that enhance a building’s durability, energy efficiency, and code compliance. The right sheathing ensures that your prefabricated panels are more than just quick-to-install—they’re built to last, protect, and perform.

Whether you’re designing a high-rise tower or a low-rise residential complex, sheathing matters. Choose wisely, and your building envelope will thank you for years to come.